Heat exchange method and structure for fluid and heat recovery system for waste water

A heat exchange structure and heat method technology, applied in the field of heat exchange, can solve the problems of ineffective heat exchange, fouling of corrugated grooves, affecting heat exchange efficiency, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

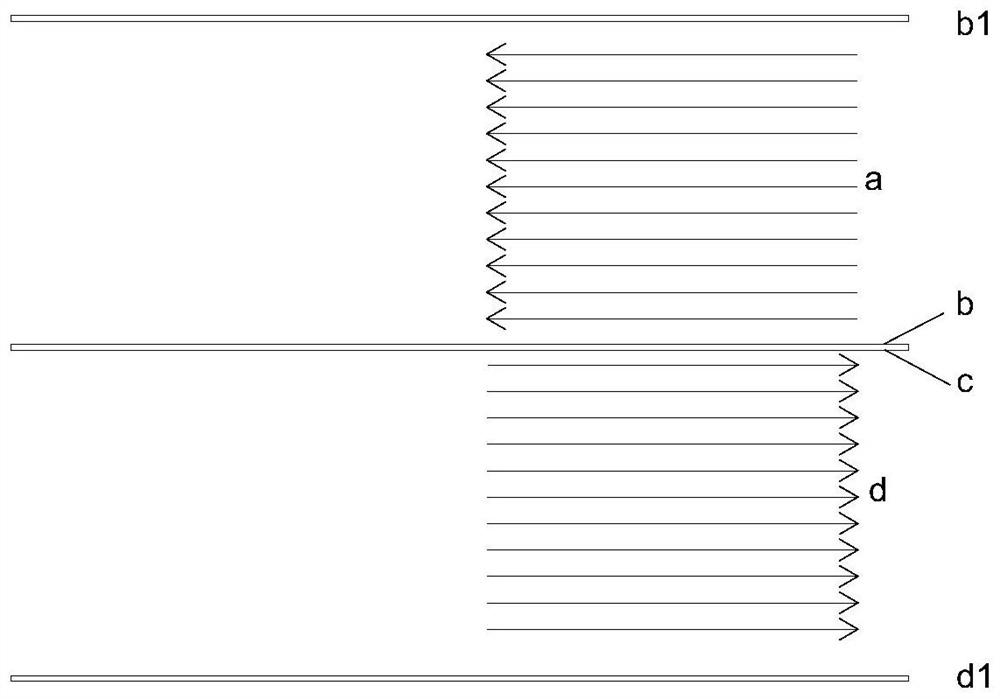

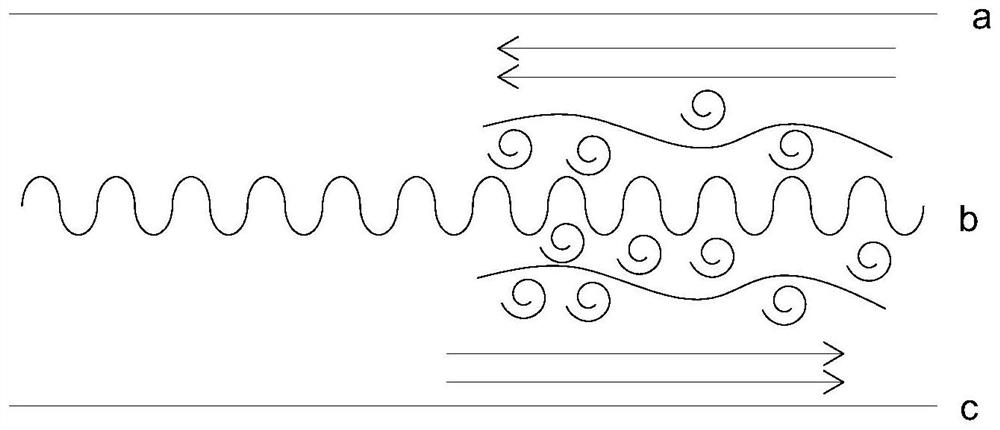

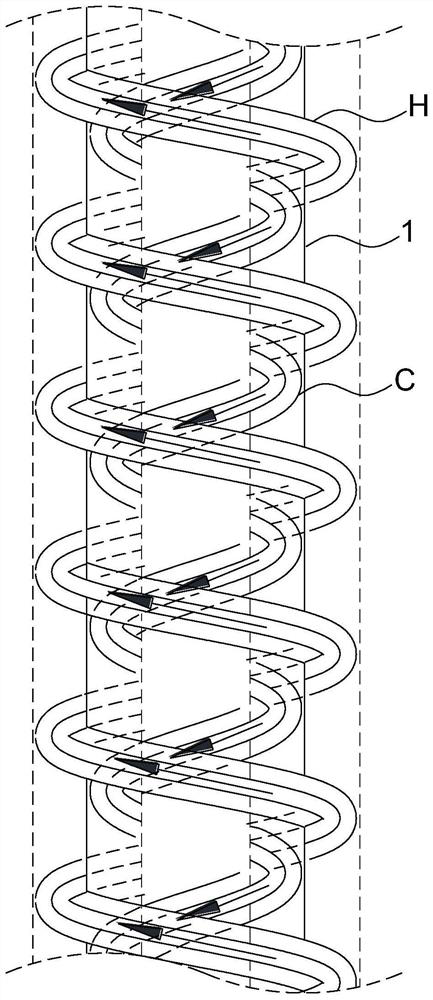

[0041] Embodiment 1 of the present application provides a heat exchange method for fluids, please refer to image 3 , specifically includes: heat exchange partition 1, cold flow C and heat flow H are separated by heat exchange partition 1, and heat exchange partition 1 is a thin-walled cylindrical structure extending axially; cold flow C and heat flow H, one of which is along the axis of the cylinder While rising up, it continues to rotate around the axis of the cylinder, while the other continues to rotate around the axis of the cylinder while going down the axis of the cylinder, and heat exchange is achieved through the heat exchange partition 1 .

[0042] The technical solution of the present application makes the cold flow C and the heat flow H do reverse spiral convection motion. Compared with the simple linear reverse convection heat transfer method, the heat exchange efficiency is significantly improved; on the other hand, compared with the linear convection heat transf...

Embodiment 2

[0051] Embodiment 2 of the present application provides a heat exchange structure for fluids, please refer to Figure 5 , including the heat exchange partition wall 2, the heat exchange partition wall 2 has an axially extending thin-walled cylindrical structure, the first flow channel 2a and the second flow channel 2b separated by the heat exchange partition wall 2, the cold flow and the heat flow, one of which is in the first flow channel. 2a spirally rises along the axial direction of the cylinder, and the other spirals downward along the axial direction of the cylinder in the second flow channel 2b, and the heat exchange is realized through the heat exchange partition 2 .

[0052] It should be noted that the heat exchange partition wall 2 can be a thin-walled cylinder, or it can be an elliptical column, prism and other axially extending structural forms extending in the axial direction. The cross-sectional dimension of the heat exchange partition wall 1 can be along the axis...

Embodiment 3

[0065] Embodiment 3 of the present application provides a waste water heat recovery system, please refer to Image 6 , including a heat exchanger 14, wherein the heat exchanger 14 adopts the heat exchange structure described in Embodiment 2.

[0066] The waste water, as a hot flow, is introduced into the first fluid inlet 7 by the flow control device 22 through the pipeline 13, spirals up rapidly in the first flow channel 2a, and then exits through the first fluid outlet 5, and the cold flow enters through the second fluid inlet 4 , spiral downward in the second flow channel 2b, and pass out from the second fluid outlet 6, use the waste heat of the waste water to heat the cold flow, and realize the waste heat recovery of the waste water.

[0067] In some possible implementations, the waste water heat recovery system of this embodiment further includes a fouling cleaning device.

[0068] Illustratively, see Image 6 , the dirt cleaning device may include a cleaning agent storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com