Gas turbine heat recovery device

A technology of heat recovery device and gas turbine, which is applied in the direction of gas turbine device, steam engine device, jet propulsion device, etc., which can solve the problems of environmental pollution, heat energy loss, high exhaust gas temperature of gas turbine, etc., to avoid air pollution, reduce consumption, and increase exposure area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

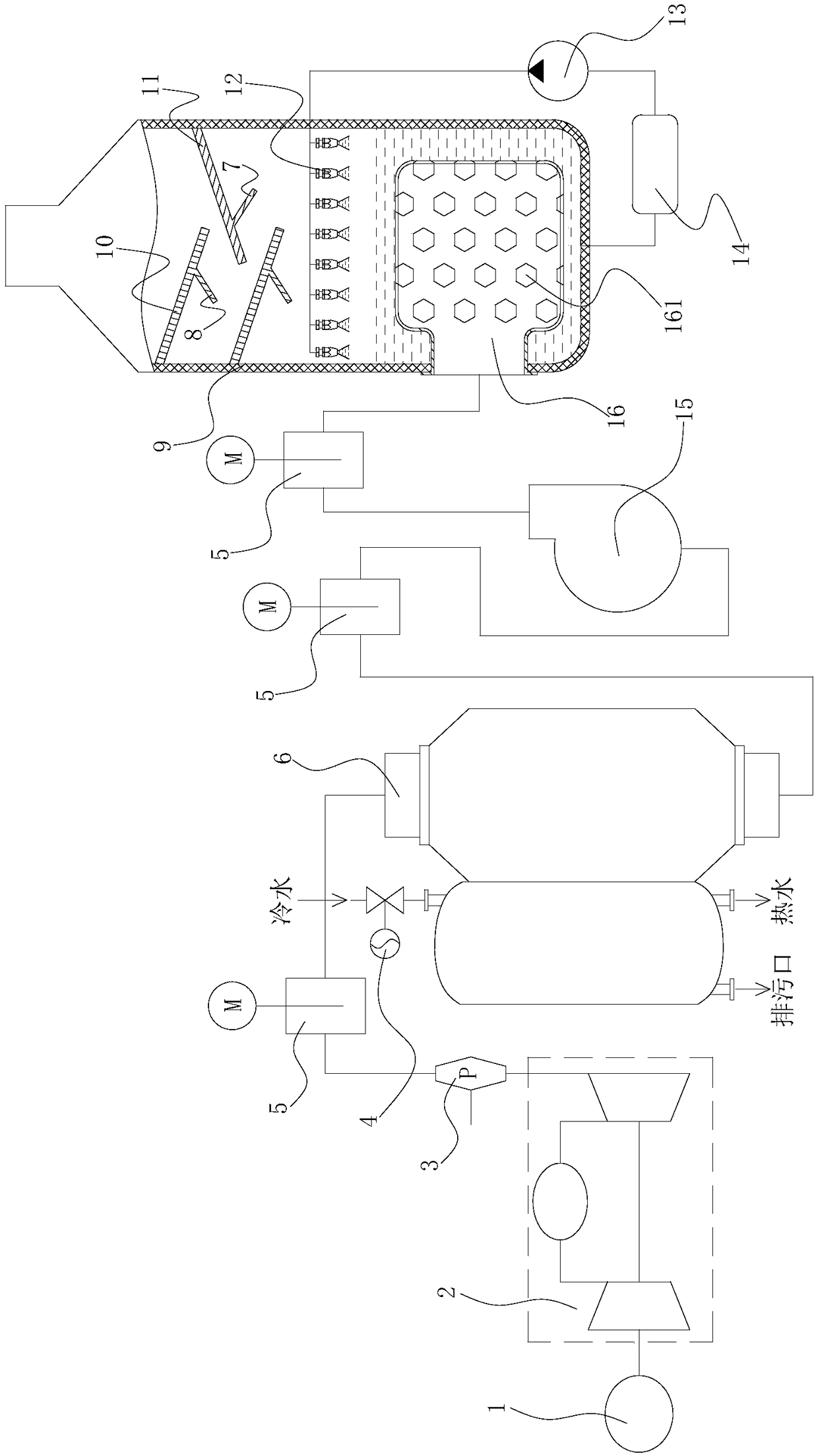

[0020] like figure 1 As shown, the present embodiment provides a gas turbine heat recovery device, including a gas turbine 2, a waste heat hot water boiler 6, a fan 15, and an exhaust discharge tower 9; the output shaft of the gas turbine 2 is connected to a working machine, such as a generator; The exhaust port is connected to the flue gas inlet of the waste heat hot water boiler 6; the flue gas outlet of the waste heat hot water boiler 6 is connected to the air inlet of the fan 15; A recovery area, a spray area, and an exhaust gas treatment area are arranged sequentially from top to bottom; a lye pool is arranged in the tail gas treatment area. 2 The exhausted tail gas is reacted to remove the acid gas in the tail gas. A gas dispersion box 16 is arranged in the lye pool; the gas dispersal box 16 is connected to the air outlet of the fan 15, and the wall of the gas dispersal box 16 is provided with a plurality of through holes communicating with the lye pool 161; through th...

Embodiment 2

[0022] like figure 1As shown, in this embodiment, on the basis of Embodiment 1, a first back hook plate 8 is fixed on the side of the first baffle plate 10 facing the second baffle plate 11; The inner wall direction of the tail gas discharge tower 9 extends; the second back hook plate 7 is fixed on the side of the second baffle plate 11 towards the first baffle plate 10; The inner wall direction of 9 extends. By setting the back hook plate, the collision time between the exhaust gas and the baffle is increased, so as to increase the amount of alkaline solution recovered and avoid the waste of alkaline solution.

Embodiment 3

[0024] Present embodiment is on the basis of embodiment 1 or 2, as figure 1 As shown, a filter device 14 is arranged between the lye pool and the circulating pump 13; the filter device 14 is located outside the tail gas discharge tower 9. Filtering device 14 is set to filter impurities such as dust in the alkaline solution to avoid clogging of circulation pump 13, and filtering device 14 is arranged outside exhaust gas discharge tower 9, which greatly facilitates the replacement of filtering device 14. In this embodiment, the filter device 14 is an activated carbon filter device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com