Three-combined supply system capable of achieving heat recovery

A technology of triple power supply and heat recovery, which is applied to compressors with reversible cycles, lighting and heating equipment, and damage protection. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

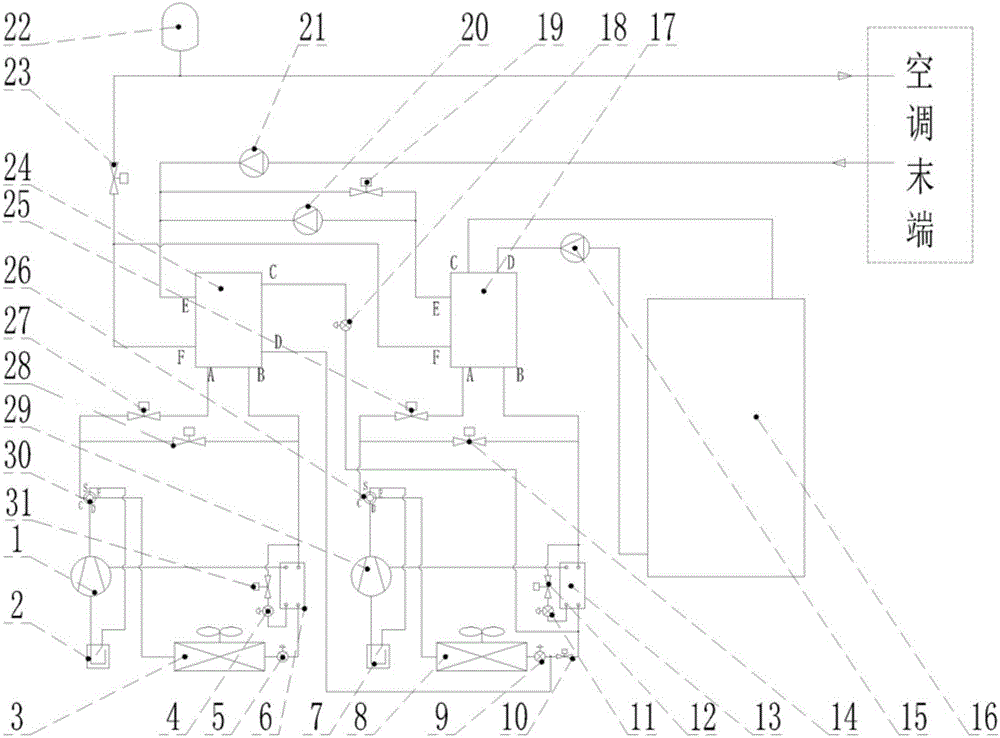

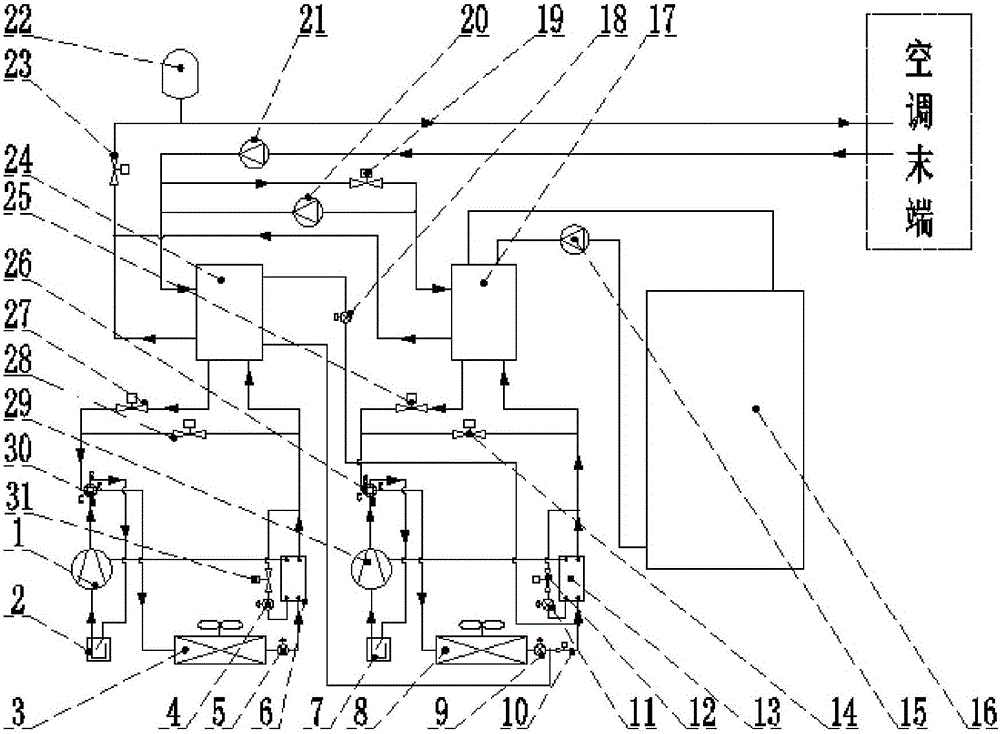

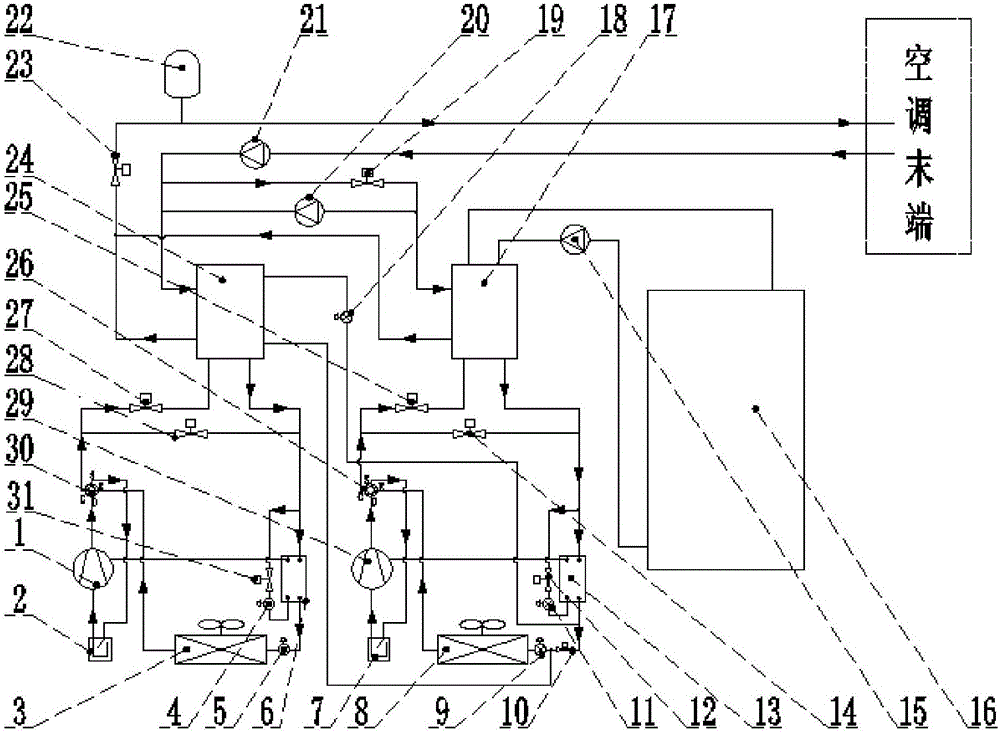

[0044] The present invention will be further described below in conjunction with the accompanying drawings. Wherein, the direction indicated by the arrow in the figure is the fluid flow direction in the channel.

[0045] Such as figure 1 , Figure 9 and Figure 10 As shown, the triple supply system that can realize heat recovery includes a first compressor 29, a first four-way valve 26, a first gas-liquid separator 7, a first evaporator 8, a first shut-off valve 25, and a second shut-off valve 14. The first throttling component 9 (using an expansion valve), the third stop valve 12, the second throttling component 11, the first economizer 13, the first heat exchanger 17, the hot water tank 16 and the first water pump 21, The first compressor 29 is connected to the first interface D of the first four-way valve 26, the second interface C of the first four-way valve 26 is connected to the first cut-off valve 25, and the first cut-off valve The valve 25 is connected to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com