A high-temperature acid flue gas deacidification device installed in a garbage incinerator

A technology of waste incinerator and incinerator, which is applied in gas treatment, separation method, dispersed particle separation, etc., can solve the problems of coking of heat exchange pipes, erosion and wear of heat exchange pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below.

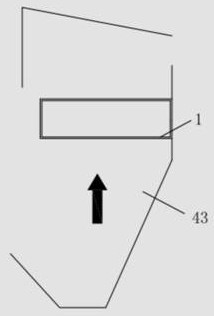

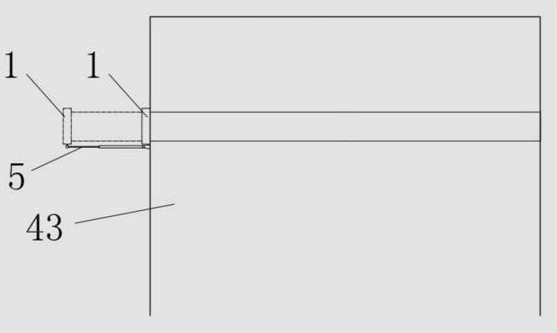

[0046] see Figure 14 , is a schematic diagram of the route of high-temperature acid flue gas flowing from the furnace 44 through the horizontal flue 45 . The high-temperature acid flue gas flows from the furnace 44 through the first channel 41, the second channel 42, the third channel 43, and the horizontal flue 45, and then flows to the reaction tower. There are several heat exchange pipes 451 in the horizontal flue 45 .

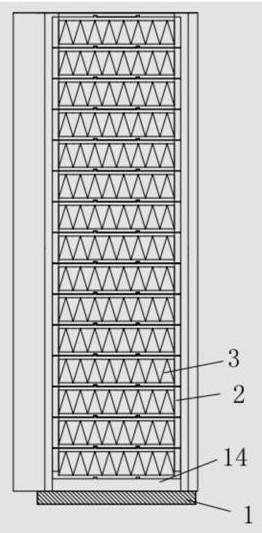

[0047] Such as Figure 1 ~ Figure 3 As shown, a high-temperature acid flue gas deacidification device installed in a garbage incinerator includes a base 1, which is slidably arranged on the upper part of the three-channel 43 in the incinerator, and can slide out from the upper part of the three-channel 43 to the outside of the incinerator Or slide into the upper part of the three channels 43 from the outside of the incinerator, the middle part of the base 1 is provided with a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com