Biomass gasifier flue gas self-purification device

A biomass gas and biomass technology, applied in the direction of combustible gas purification, combustible gas purification/transformation, gasification process, etc., can solve the problems of ineffective filtration of gas, unbalanced feed, etc., to reduce the dust content of the gas, Guaranteed output and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawings and specific use.

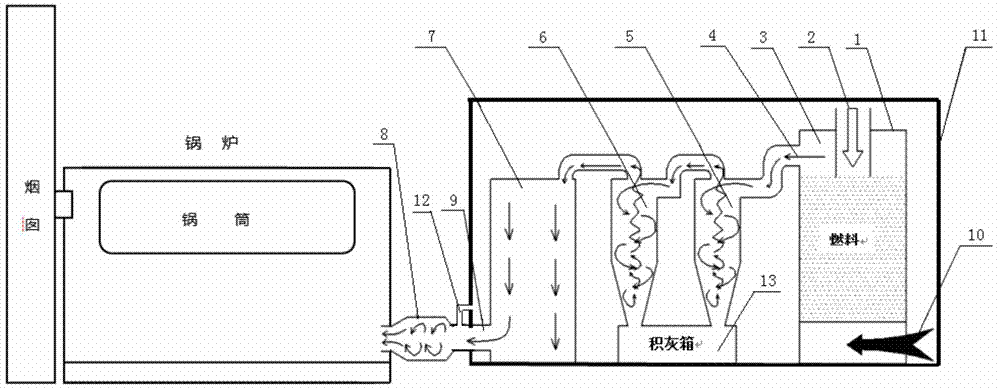

[0022] The structure of the flue gas self-purification device of the biomass gasification furnace of the present invention is as follows figure 1 as shown,

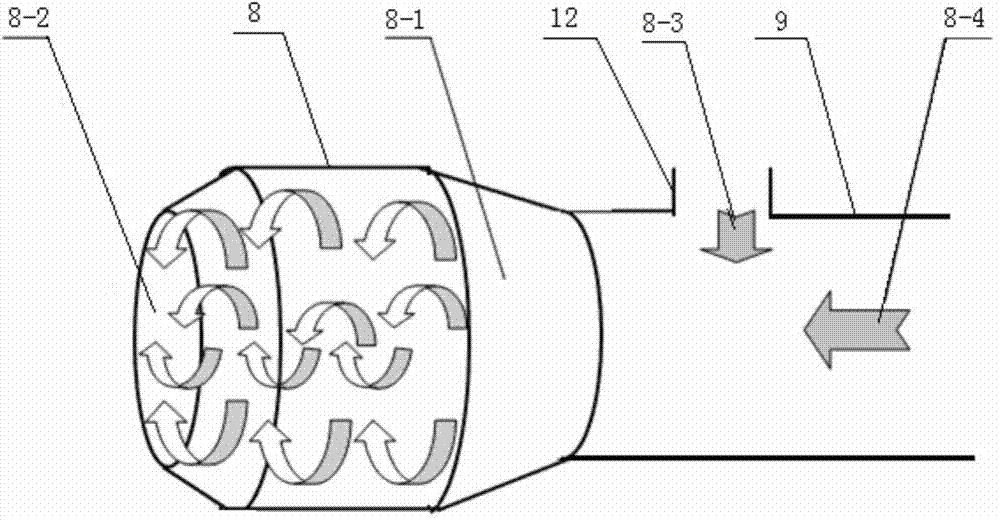

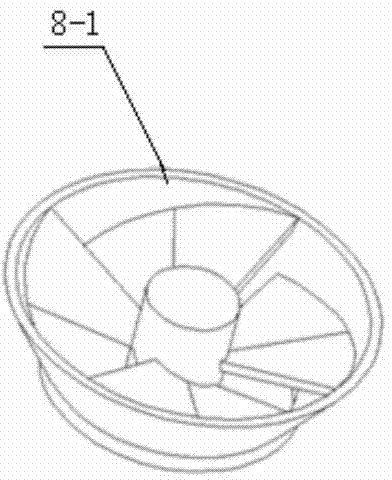

[0023] Biomass gasification furnace flue gas self-purification system device consists of biomass gasification furnace 1, first cyclone separator 5, second cyclone separator 6, settling chamber 7, burner head 8, ash accumulation box 13 and insulation layer 11 constitute. The biomass gasification furnace 1 , the first cyclone separator 5 , the second cyclone separator 6 , the settling chamber 7 , and the ash accumulation box 13 are arranged in the insulation layer 11 .

[0024] The biomass gasifier 1 is provided with a feed pipe 2 , a biomass gas outlet 4 , a settling zone 3 and an air inlet 10 . The first cyclone separator 5 and the second cyclone separator 6 are respectively provided with a biomass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com