A system and method for improving the utilization rate of cracking ethylene raw materials

A cracking technology for ethylene production and utilization rate, which is applied in organic chemistry, hydrocarbon oil treatment products, hydrocarbon oil treatment, etc., can solve the problems of inability to split furnace cracking, difficulty in setting optimal cracking reaction temperature, optimal cracking residence time, Problems such as low ethylene yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] This embodiment is an exemplary embodiment of the present invention.

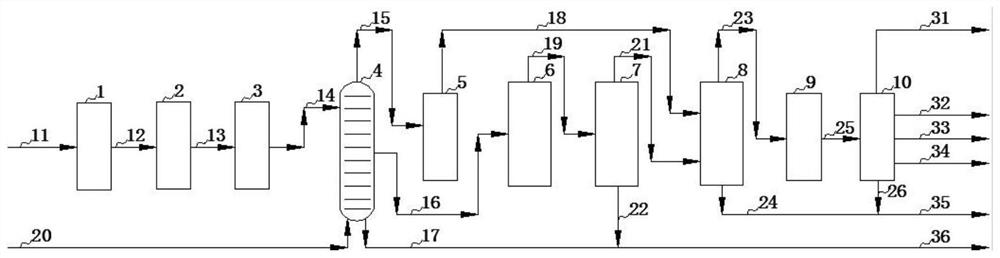

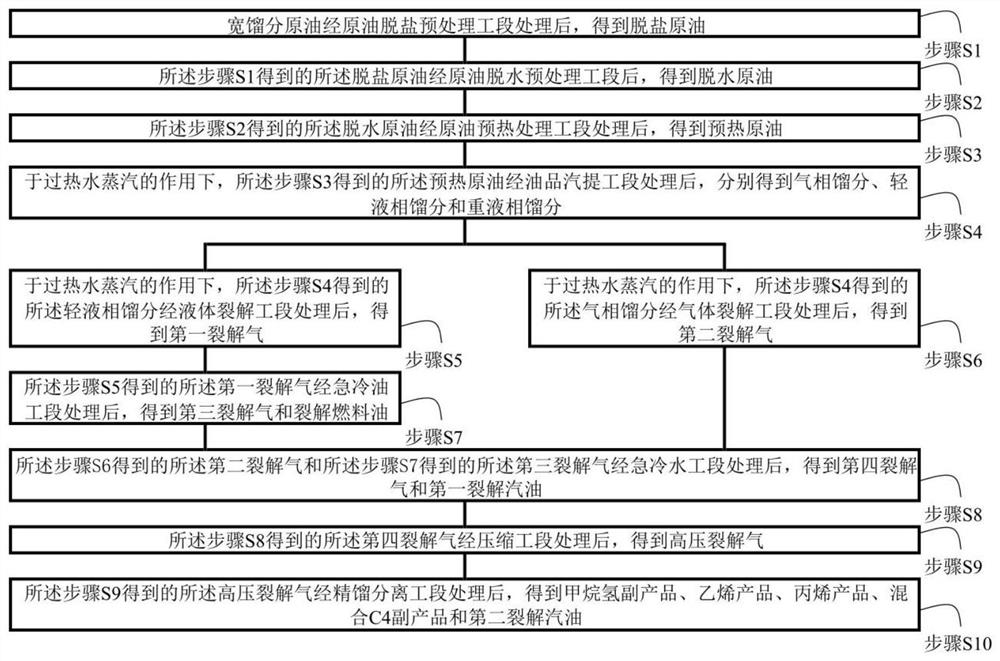

[0079] Such as figure 1 As shown, a system for improving the utilization rate of cracking ethylene raw materials, including crude oil desalination pretreatment section 1, crude oil dehydration pretreatment section 2, crude oil preheating treatment section 3, oil stripping section 4, gas cracking section 5, liquid Cracking Section 6, Quenching Oil Section 7, Quenching Water Section 8, Compression Section 9, Distillation and Separation Section 10, Crude Oil Desalting Pretreatment Section 1, Crude Oil Dehydration Pretreatment Section 2, Crude Oil Preheating Section 3 and Oil Stripping Section 4 is connected through pipelines, the gas cracking section 5 is connected with the oil stripping section 4 and the quenching water section 8 respectively through pipelines, the liquid cracking section 6 is connected with the oil stripping section 4 and the quenching oil section 7 respectively through pipelines, and...

Embodiment 2

[0136] In order to verify the reliability of the above-mentioned system and method for improving the utilization rate of cracking ethylene raw materials, the inventors have carried out a group of control experiments, as follows:

[0137] Experimental group 1

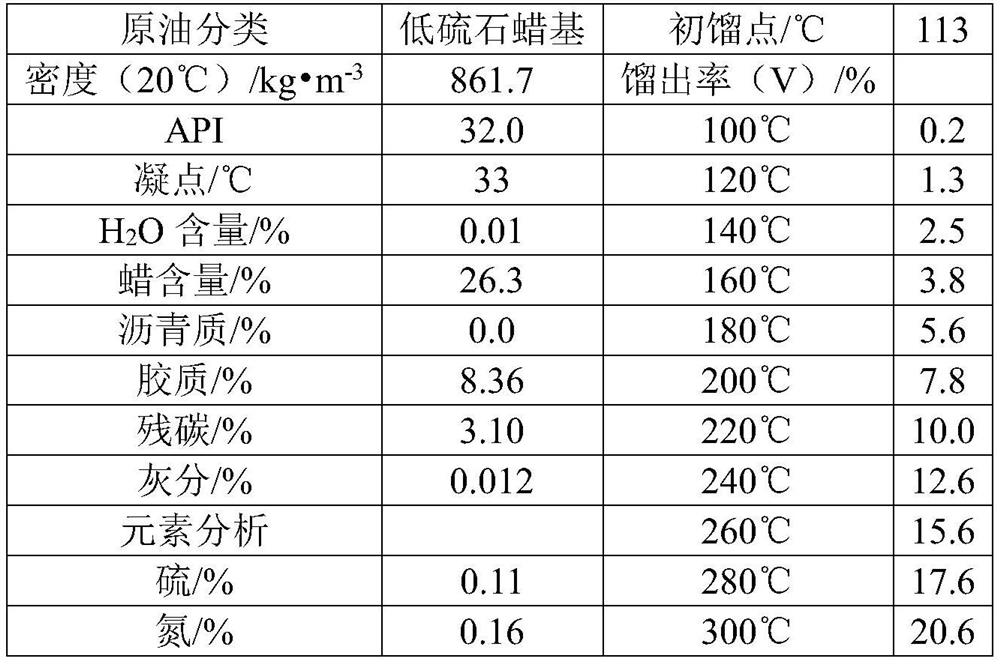

[0138] A petroleum factory that adopts the system and method for improving the utilization rate of cracking ethylene raw materials of the present invention has an ethylene production scale of 1 million tons / year, and the wide-cut crude oil is Daqing crude oil. The main properties of this crude oil are as follows:

[0139]

[0140]

[0141] Its pyrolysis ethylene method is with embodiment 1, and concrete process parameter is as follows:

[0142] Crude oil desalting pretreatment section 1:

[0143] Inlet: The operating pressure is 0.48MPaA, and the operating temperature is 27°C;

[0144] Outlet: The operating pressure is 0.43MPaA, and the operating temperature is 27°C;

[0145] The desalination rate is 99.0%;

[...

Embodiment 3

[0175] Experimental group 2

[0176] A petroleum factory that adopts the system and method for improving the utilization rate of cracking ethylene raw materials of the present invention has an ethylene production scale of 1,000,000 tons / year, and the wide-cut crude oil is Shengli crude oil. The main properties of this crude oil are as follows:

[0177] Crude oil classification Sulfur intermediate Initial boiling point / ℃ 108 Density(20℃) / kg·m -3

923.6 Distillation rate (V) / % APIs 21.1 100℃ 0.91 Freezing point / ℃ 14 120℃ 1.05 h 2 O content / %

2.50 140℃ 2.21 Wax content / % 9.1 160℃ 3.19 Asphaltenes / % 1.42 180℃ 4.60 Colloid / % 19.90 200℃ 5.82 Carbon residue / % 7.22 220℃ 7.06 Ash / % 0.040 240℃ 8.16 Elemental analysis 260℃ 9.29 sulfur / % 1.03 280℃ 11.55 nitrogen / % 0.37 300℃ 13.82 Nickel / μg·g -1

26.38 400℃ 29.70 Vanadium / μg·g -1

1.61 500℃ 47.30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com