A kind of synthetic method of 2,6-dichloropyridine

A technology for dichloropyridine and a synthesis method, applied in the field of chemistry, can solve problems such as unsatisfactory selectivity of 2,6-dichloropyridine, and achieve the effects of prolonged reaction time, reduced speed and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 227 grams of 2-chloropyridine (2.0 moles) in a four-mouth jacketed glass reactor equipped with a reflux condenser, an air guide tube, a thermowell and a mechanical stirrer. Heating to 160°C, under the irradiation of 40W ultraviolet lamp, passing chlorine gas at a rate of 0.22mol / h for about 10 hours under normal pressure to react,

[0023] In the meantime, by Petite The oil bath circulation system realizes the temperature program of the reactor, so that the internal temperature of the reaction bottle gradually rises to 190°C. After the introduction of chlorine gas, the reaction solution was cooled to room temperature under a nitrogen atmosphere, and samples were taken for quantitative analysis by HPLC (the analysis results are shown in Table 1).

Embodiment 2

[0025] The reaction conditions were exactly the same as in Example 1, except that a 40W blue light was used as the light source (reaction results are shown in Table 1).

Embodiment 3

[0027] The reaction conditions are exactly the same as in Example 1, except that a 40W fluorescent lamp is used as the light source (reaction results are shown in Table 1).

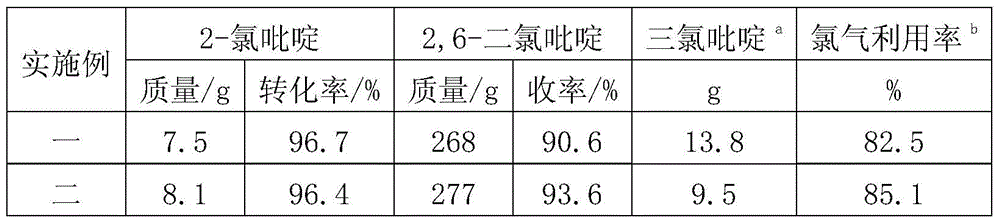

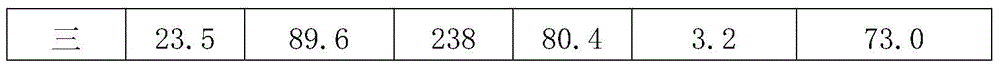

[0028] Table 1. Chlorination reaction results using different light sources

[0029]

[0030]

[0031] a Trichloropyridine is a mixture of 2,3,6-trichloropyridine and 2,4,6-trichloropyridine; b Chlorine gas utilization refers to the ratio of the amount of chlorine gas consumed to generate 2,6-dichloropyridine to the total amount of chlorine gas introduced

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com