Quick-disassembly flexible large-diameter annular seam welding tool

A tooling and ring welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as poor stability, low assembly efficiency, and difficult movement, and achieve good stability, stable overall structure, and high repeatable assembly accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

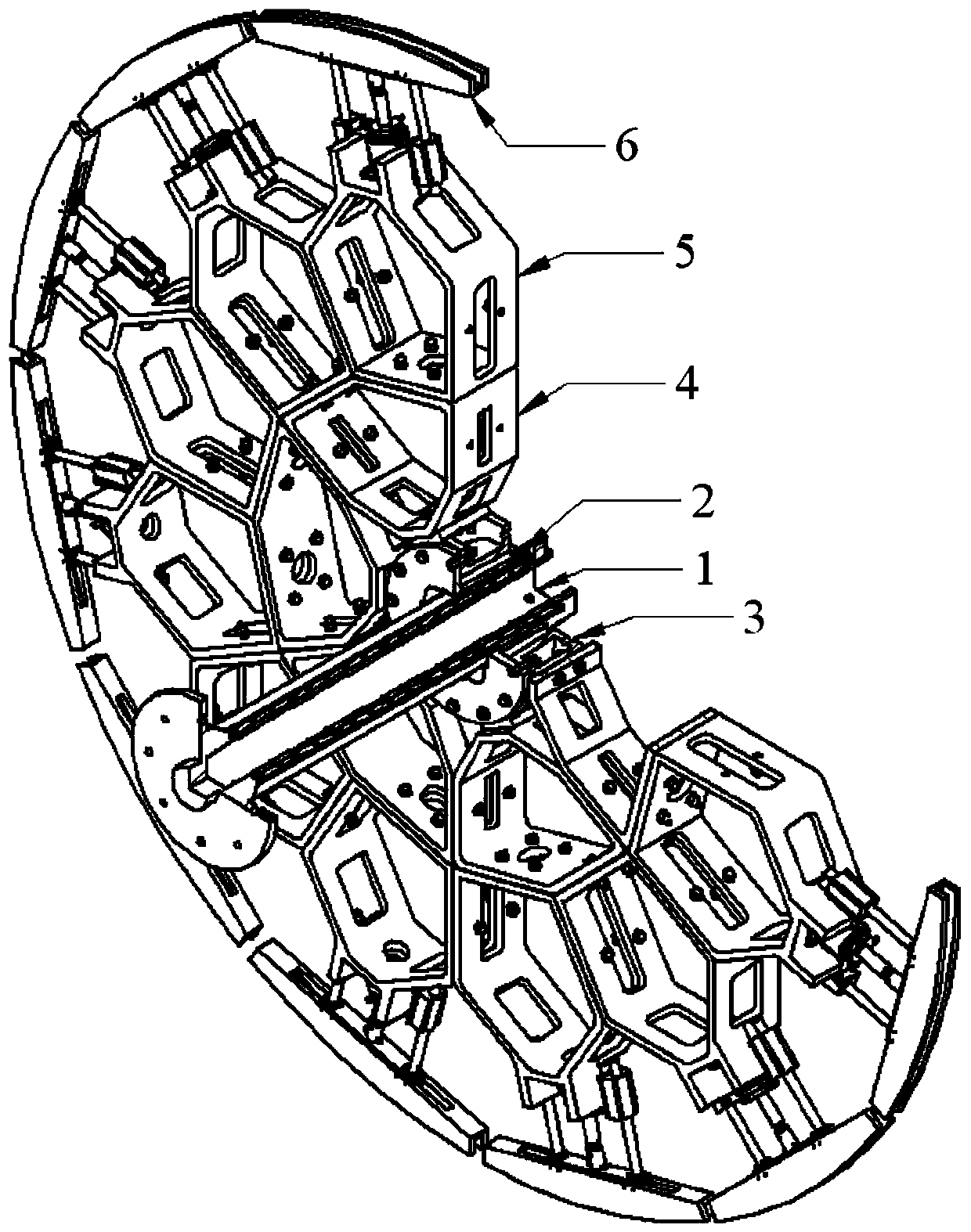

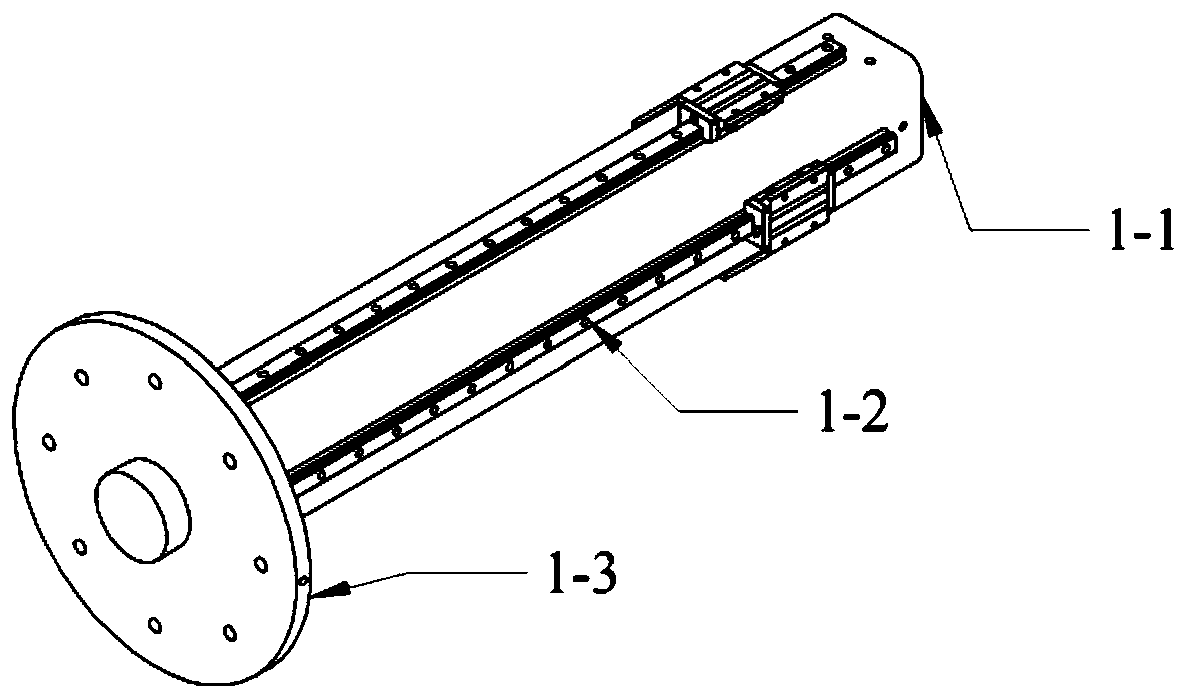

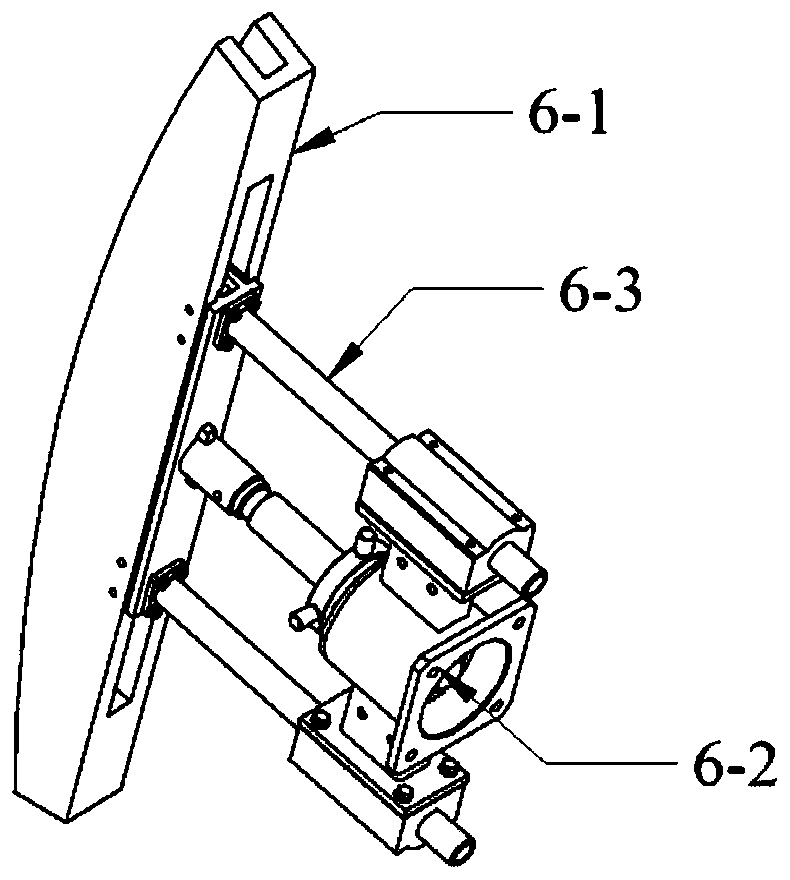

[0028] The present invention is a guide rail type large-scale cabin column girth welding tooling, which includes a square shaft 1, a fixed flange 2, a shaft sleeve flange 3, an inner frame 4, an outer frame 5 and an outer supporting arc block assembly 6; Detachable circumferential uniform structure, from the inside to the outside are square shafts, including square shaft 1, fixed flange 2, bushing flange 3, inner frame 4, outer frame 5 and outer support arc block assembly 6; the square shaft 1 is located The center position of the entire tooling; either end of the square shaft 1 is welded with a connecting flange to achieve assembly and fixation with the positioner of the welding system. There are four parallel linear guides on all sides to smoothly move the entire tooling along the axis; fixed Four sliding blocks are arranged on the inner side of flange 2 to realize the connection with the linear guide on the square shaft 1 and move smoothly along the axial direction; the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com