Water treatment equipment for construction site

A water treatment equipment and construction site technology, which is applied in the field of engineering management and water circulation, can solve the problems of miniaturization, integration and high efficiency, large footprint, and complex layout, etc., to achieve small footprint and simple layout , the effect of smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

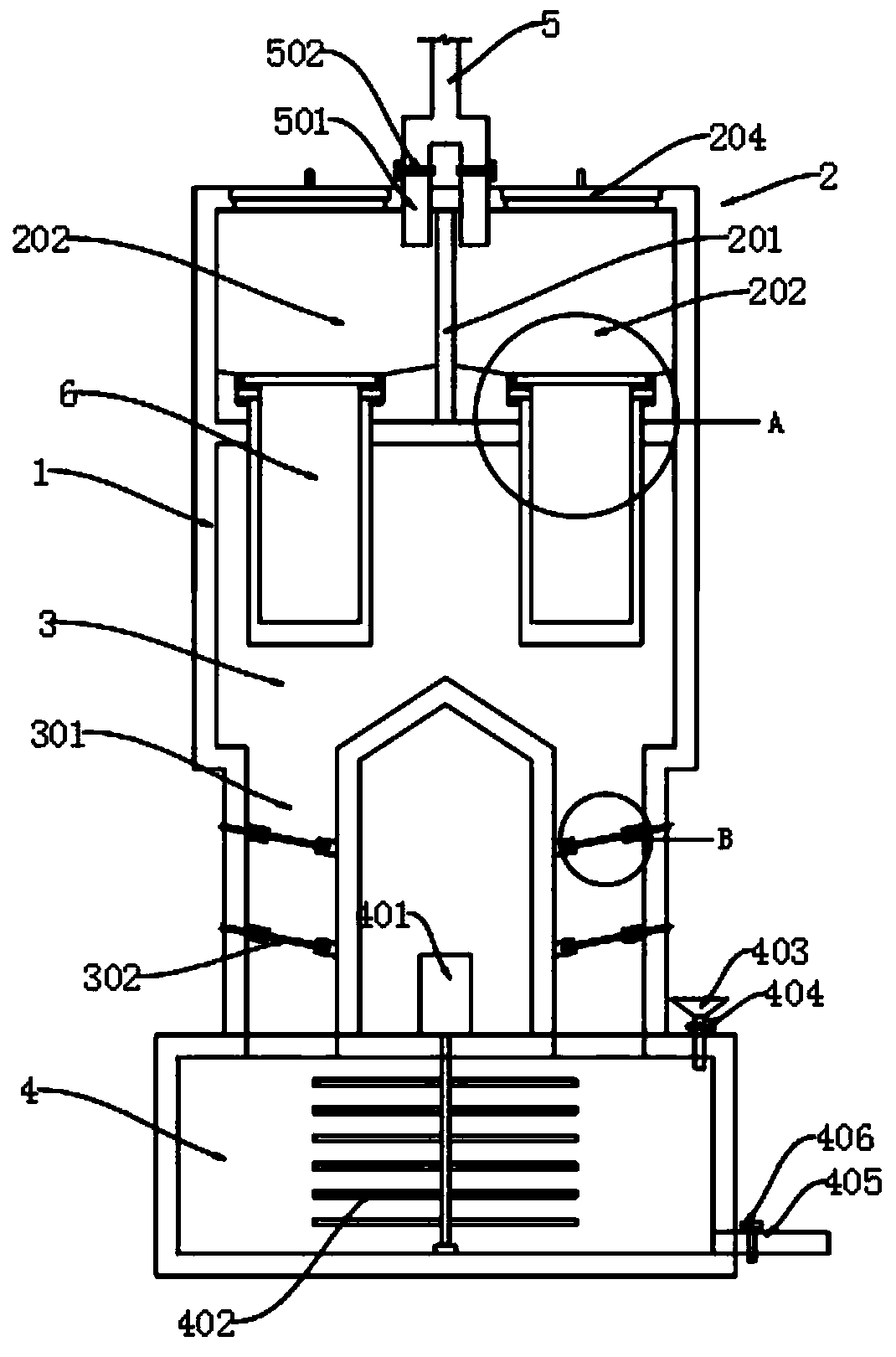

[0037] as attached figure 1 to attach Figure 8 Shown:

[0038] The construction site water treatment equipment of the present invention includes a housing 1 and a water inlet main pipe 5; the housing 1 includes an upper filter chamber 2, a lower filter chamber 3 and a clean room 4, and the upper filter room 2, the lower filter room 3 and the clean room 4 Connected sequentially from top to bottom, the water inlet main pipe 5 is installed on the top of the upper filter chamber 2 and inserted into the upper filter chamber 2, and the first-stage filter mechanism 6 is clamped on the bottom of the upper filter chamber 2 and inserted into the lower filter chamber 3 middle.

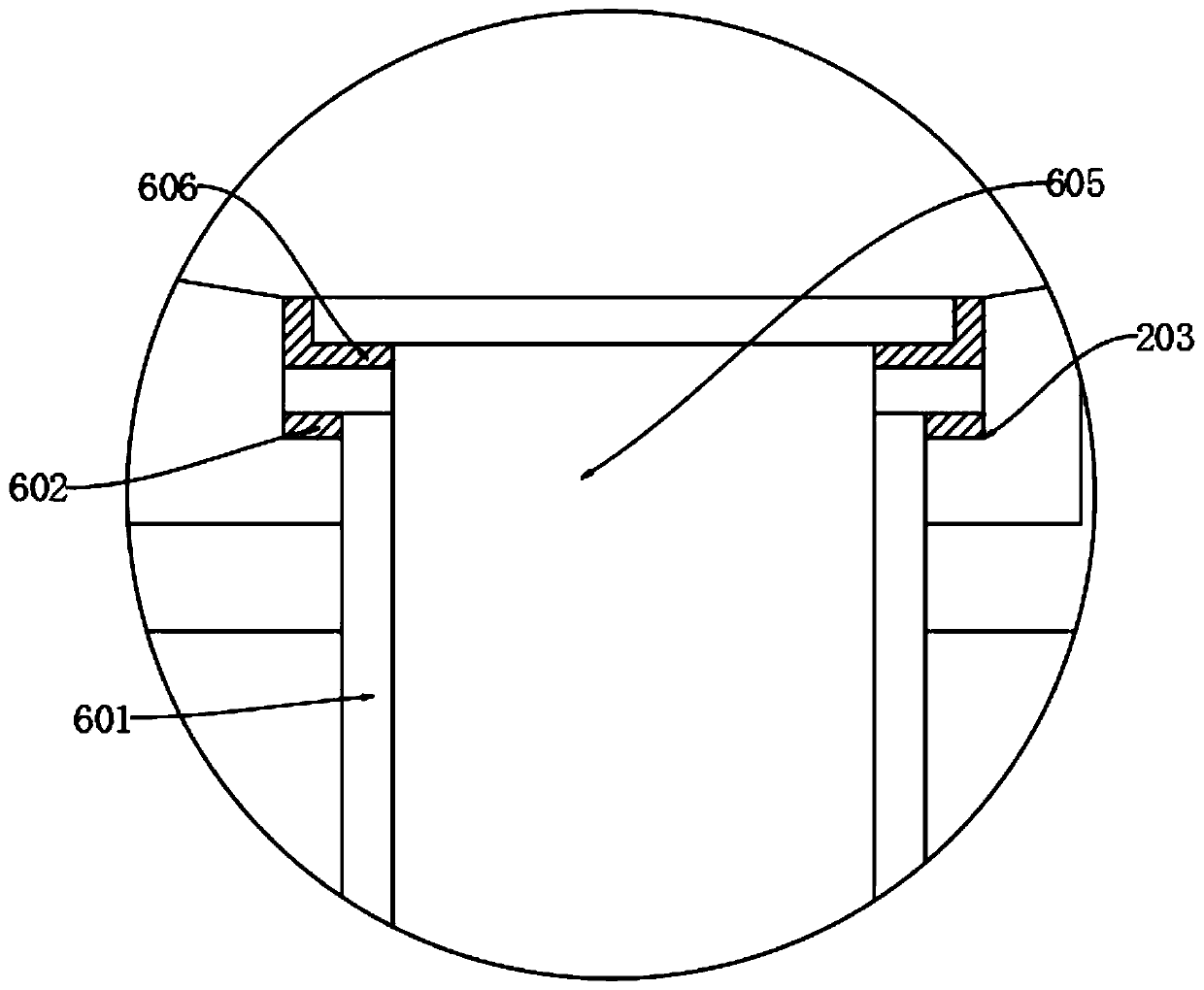

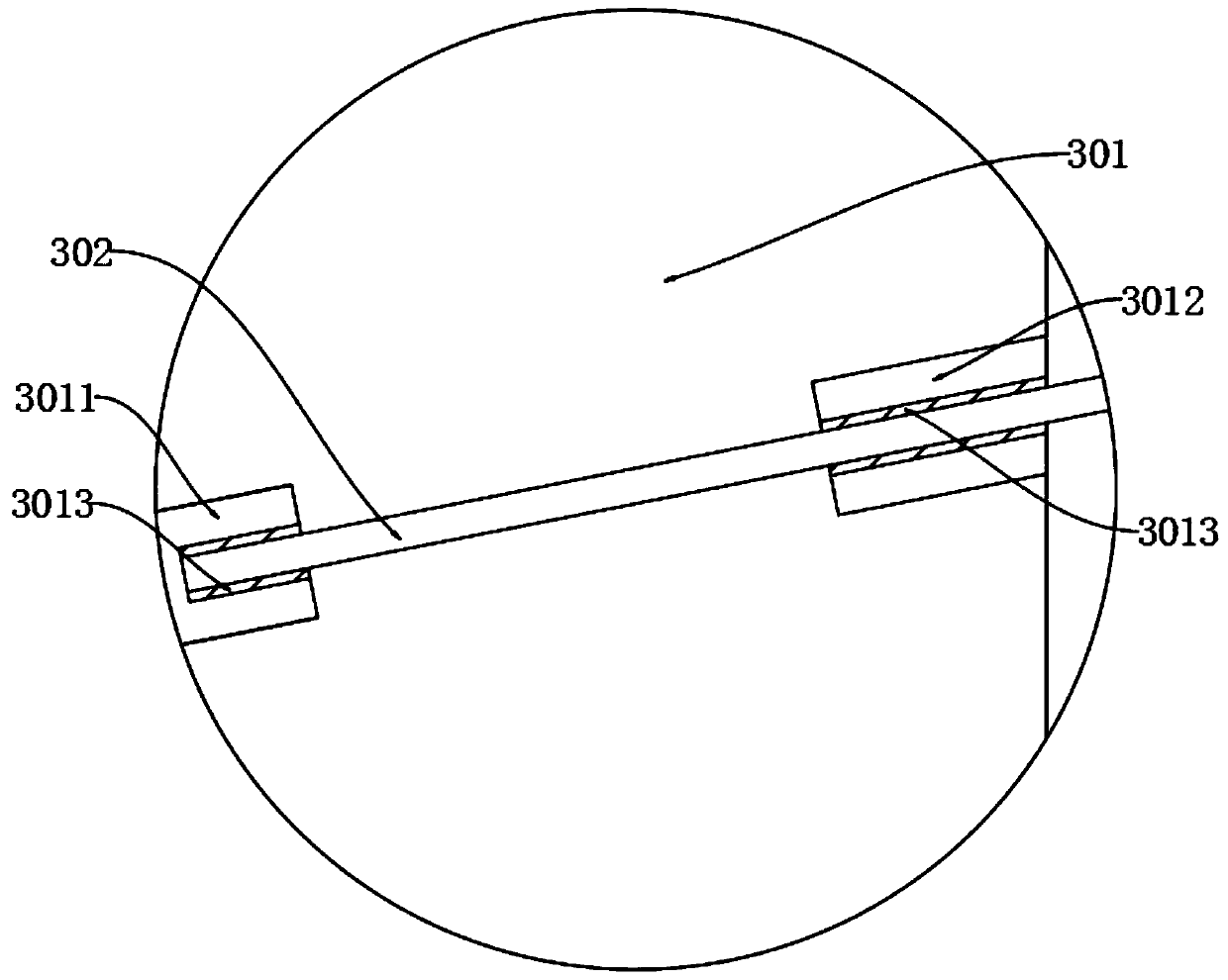

[0039] Wherein, the upper filter chamber 2 includes a partition 201, a sub-filter chamber 202, a stepped perforation 203, a circular buckle groove 204 and a buckle cover 205, and the inner middle of the upper filter chamber 2 is provided with a partition 201 and is separated into two groups of filters. Cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com