A kind of reinforced concrete nano admixture, preparation method and application thereof

A concrete and admixture technology, applied in the field of preparation and reinforced concrete nano-admixture, can solve the problems of insufficient strength and high dosage of the admixture, and achieve the effects of excellent performance, excellent performance and controllable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A reinforced concrete nano admixture, comprising the following components, calculated in parts by weight:

[0047] 80 parts of nano-scale silicon dioxide, 0.1 part of synthetic polymer viscosifying material, 1.5 parts of sodium thiocyanate, 1 part of powder polycarboxylate high-performance water reducer, 0.5 part of carbonamide, 0.1 part of sodium nitrite, nitric acid 0.5 part of sodium, 1 part of potassium aluminum sulfate dodecahydrate, 0.1 part of powder defoamer.

[0048] Preparation method of reinforced concrete nano admixture

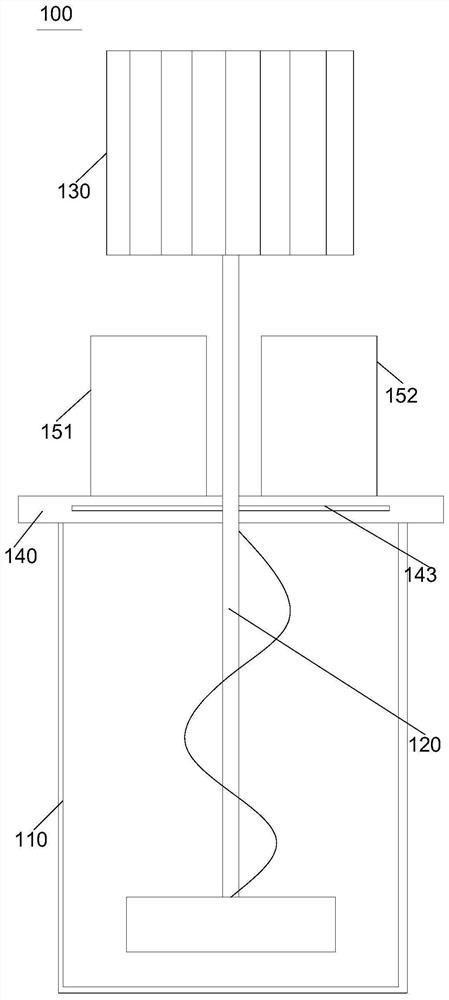

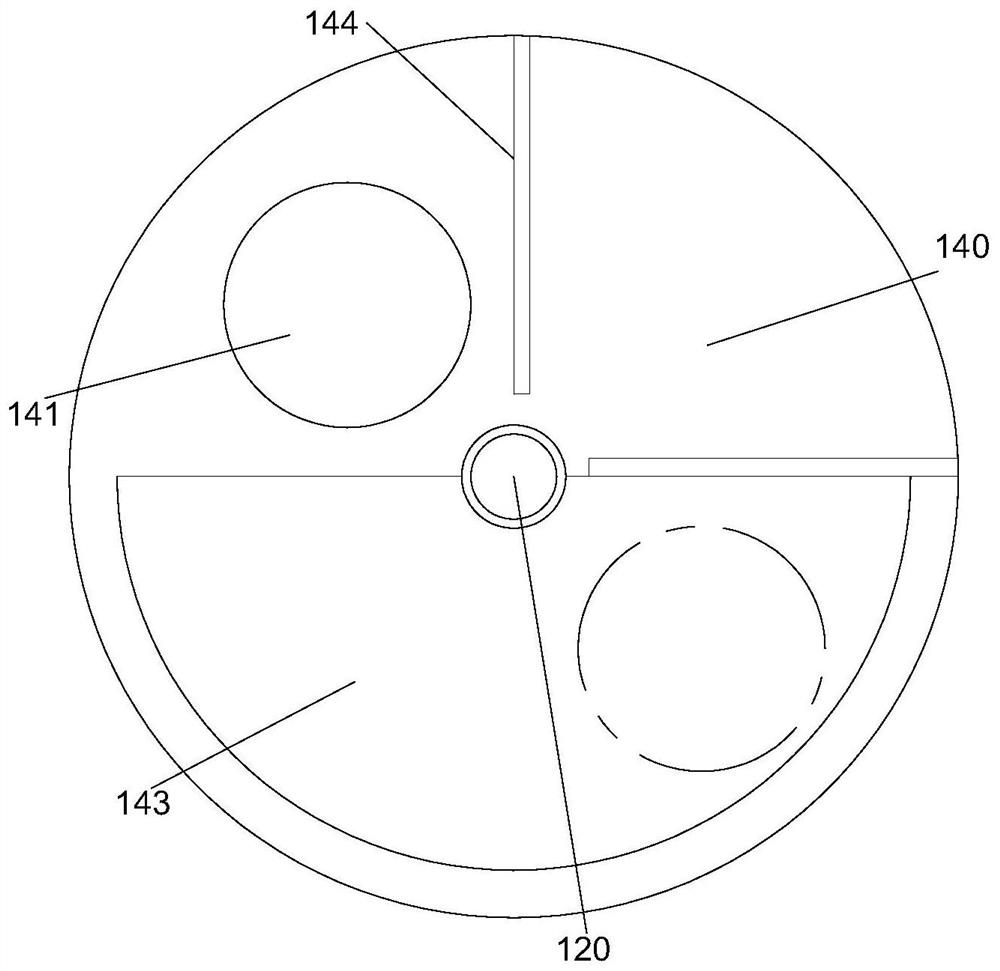

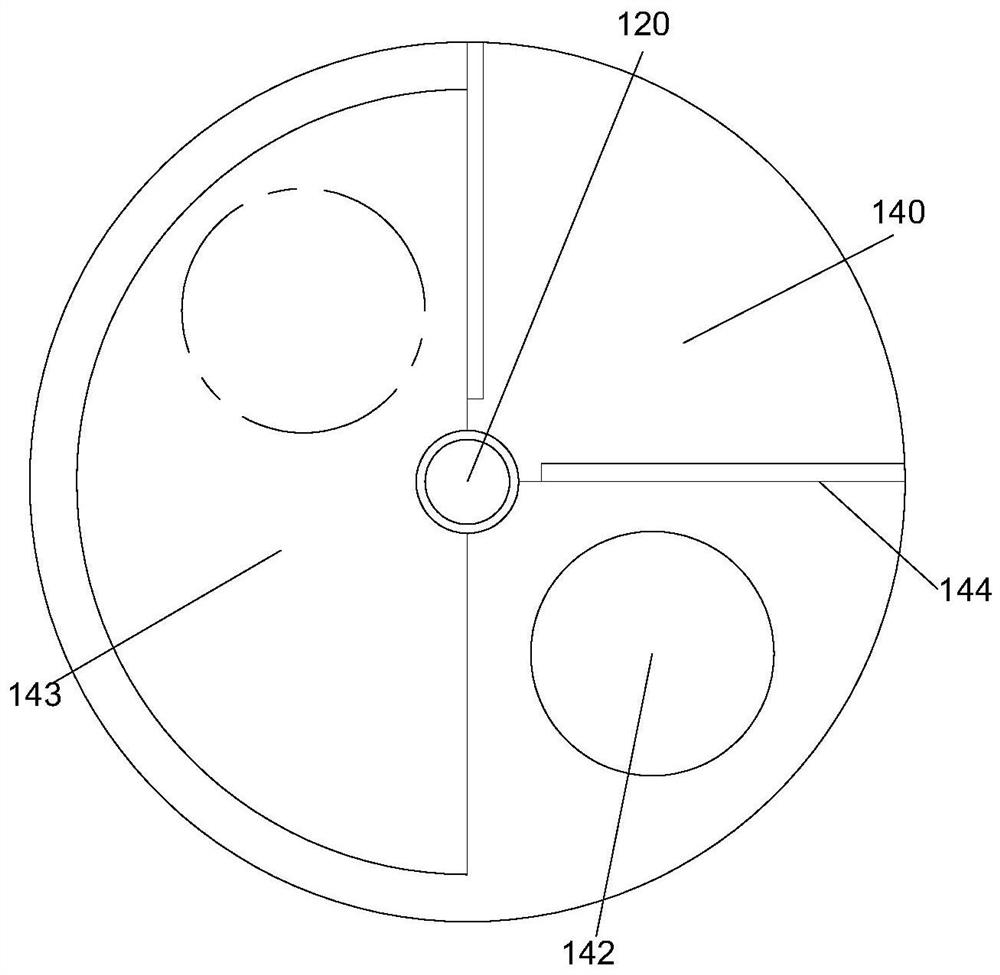

[0049] S1: Put nano-scale silica, synthetic polymer viscosifying material and powder polycarboxylate high-performance water reducer into the mixing tank 110, and carry out the first mixing under the forward rotation of the driving motor 130. Stir and mix, the stirring reaction time is 10 minutes, the stirring speed is 100 r / min, and the first mixed powder is obtained.

[0050] S2: After step S1 reacts to obtain the first mixed powder, put...

Embodiment 2

[0054] A reinforced concrete nano admixture, 89 parts of nano-scale silicon dioxide, 0.2 parts of synthetic polymer viscosifying material, 1.0 part of sodium thiocyanate, 2 parts of powder polycarboxylate high-performance water reducer, 1.2 parts of carbonamide 0.5 parts of sodium nitrite, 1.2 parts of sodium nitrate, 2 parts of potassium aluminum sulfate dodecahydrate, and 0.1 part of powder defoamer.

[0055] Preparation method of reinforced concrete nano admixture

[0056] S1: Put nano-scale silica, synthetic polymer viscosifying material and powder polycarboxylate high-performance water reducer into the mixing tank 110, and carry out the first mixing under the forward rotation of the driving motor 130. Stir and mix, the stirring reaction time is 12 minutes, the stirring speed is 120 r / min, and the first mixed powder is obtained.

[0057] S2: After step S1 reacts to obtain the first mixed powder, put the potassium aluminum sulfate dodecahydrate and powder defoamer into the...

Embodiment 3

[0061] A reinforced concrete nano admixture, 88.5 parts of nano-scale silicon dioxide, 0.3 parts of synthetic polymer viscosifying material, 1.2 parts of sodium thiocyanate, 4 parts of powder polycarboxylate high-performance water reducer, 1 carbonamide 0.8 parts of sodium nitrite, 1 part of sodium nitrate, 3 parts of potassium aluminum sulfate dodecahydrate, and 0.2 parts of powder defoamer.

[0062] Preparation method of reinforced concrete nano admixture

[0063] S1: Put nano-scale silica, synthetic polymer viscosifying material and powder polycarboxylate high-performance water reducer into the mixing tank 110, and carry out the first mixing under the forward rotation of the drive motor 130. Stir and mix, the stirring reaction time is 15 minutes, the stirring speed is 150 r / min, and the first mixed powder is obtained.

[0064] S2: After step S1 reacts to obtain the first mixed powder, put the potassium aluminum sulfate dodecahydrate and powder defoamer into the first stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com