Method for separating and purifying byproduct isopropyl hydrazine produced in preparation of hydrazine hydrate from ketazine

A technology of ketazine hydrazine hydrate and isopropylhydrazine, which is applied in the field of separation and purification of by-products of ketazine hydrazine hydrate, can solve the problems of cumbersome operation process, many steps in the preparation method, and high parameter requirements, so as to improve economic benefits, effect of problem solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

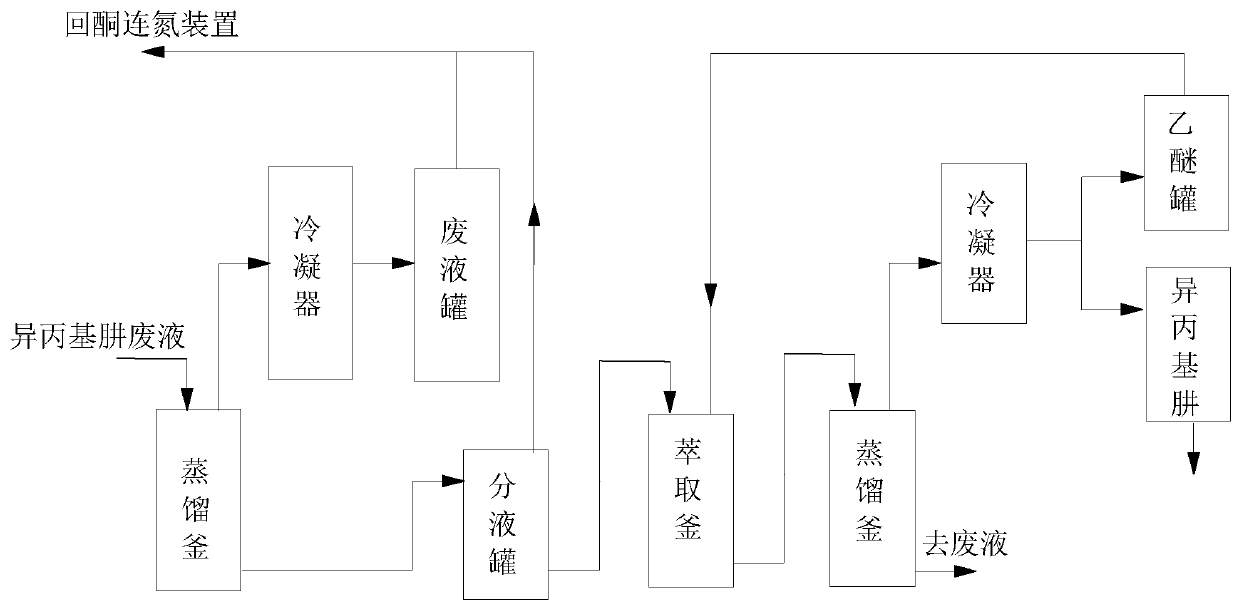

Method used

Image

Examples

Embodiment 1

[0029] Add 500 kg of a solution containing 10.30% isopropylhydrazine into the distillation still, heat to carry out distillation, control the temperature of the still still at 100-105°C, control the distillation temperature at 95-98°C, and the concentration of isopropylhydrazine after distillation is 78.25% , standing for stratification, standing for 0.5h, there is an obvious phase interface, the stratification is over, add the oil phase to the extraction kettle, add 300kg ether for extraction three times each time, combine the extracts into the distillation kettle, distill out the ether, and collect at 750mmHg 49.95kg of isopropylhydrazine was obtained from the fraction at 106-108°C, the content of which was analyzed to be 95.52%, and the calculated yield was 92.64%.

Embodiment 2

[0031]Add 500 kg of a solution containing 10.05% isopropylhydrazine into the still, heat to carry out distillation, control the temperature of the still still at 100-108°C, control the distillation temperature at 95-100°C, and the concentration of isopropylhydrazine after distillation is 80.5% , standing for stratification, standing for 1h, there is an obvious phase interface, the stratification is over, add the oil phase to the extraction kettle, add 350kg ether for extraction three times each time, combine the extracts into the distillation kettle, distill out the ether, and collect at 750mmHg 46.96kg of isopropylhydrazine was obtained from the fraction at 106-108°C, the content of which was analyzed to be 98.84%, and the calculated yield was 94.55%.

Embodiment 3

[0033] Add 500 kg of a solution containing 11.3% isopropylhydrazine into the distillation still, heat to carry out distillation, control the temperature of the still still at 101-108°C, control the distillation temperature at 95-100°C, and the concentration of isopropylhydrazine after distillation is 81.62% , standing for stratification, standing for 0.5h, there is an obvious phase interface, the stratification is over, add the oil phase to the extraction kettle, add 300kg ether for extraction three times each time, combine the extracts into the distillation kettle, distill out the ether, and collect at 750mmHg 53.0kg of isopropylhydrazine was obtained from the fraction at 106-108°C, the content of which was analyzed to be 98.50%, and the calculated yield was 92.39%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com