Miniature double-vacuum furnace tube and use method thereof

A dual vacuum and furnace tube technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of large size, easy damage, low gas content, etc., and achieve cost reduction, good air tightness, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

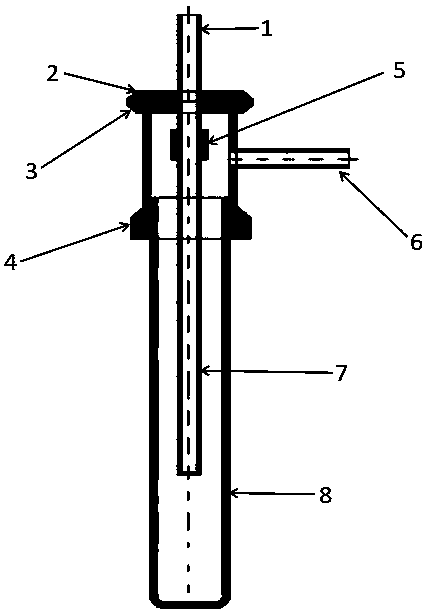

[0042] Example 1 as figure 1 Shown, a kind of miniature double vacuum furnace tube, it comprises stainless steel through pipe 1, stainless steel bypass pipe 6, tool high vacuum or ultra-high vacuum airtight blind tube 7 and tool vacuum airtight outer tube 8. One end of the outer tube 8 is open, and the other end is closed; the open end of the outer tube 8 is connected with a vacuum joint 4, and the vacuum joint 4 is provided with a KF type flange 3 and a stainless steel bypass pipe 6.

[0043] The KF-type flange 3 is connected with the KF-type pipe-through flange 2, and the center of the KF-type pipe-through flange 2 is provided with a stainless steel through-pipe 1; corresponding to the stainless steel through-pipe 1 on the outside of the KF-type pipe-through flange 2, the port is connected to the instrument Equipment interface; Corresponding to the stainless steel through-pipe 1 port inside the KF-type through-pipe flange 2, there is a high-vacuum or ultra-high-vacuum air-ti...

Embodiment 2

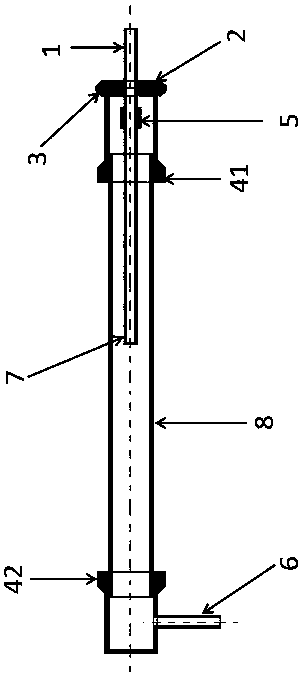

[0055] Example 2 as figure 2 Shown, a kind of miniature double vacuum furnace tube, it comprises stainless steel through pipe 1, stainless steel bypass pipe 6, tool high vacuum or ultra-high vacuum airtight blind tube 7 and tool vacuum airtight outer tube 8. Both ends of the outer tube 8 are open; one open end of the outer tube 8 is connected with a first vacuum joint 41, and the other open end is connected with a second vacuum joint 42; the first vacuum joint 41 is provided with a KF type flange 3; The second vacuum joint 42 is provided with a stainless steel bypass pipe 6 .

[0056]The KF-type flange 3 is connected with the KF-type pipe-through flange 2, and the center of the KF-type pipe-through flange 2 is provided with a stainless steel through-pipe 1; corresponding to the stainless steel through-pipe 1 on the outside of the KF-type pipe-through flange 2, the port is connected to the instrument Equipment interface; Corresponding to the stainless steel through-pipe 1 por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com