Material parameter acquisition method based on DIC technology

A material parameter and acquisition method technology, applied in the direction of analyzing materials, applying stable tension/pressure to test material strength, electrical digital data processing, etc., can solve the problem of inaccurate material parameters, incomplete deformation, and residual stress on the surface of samples And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

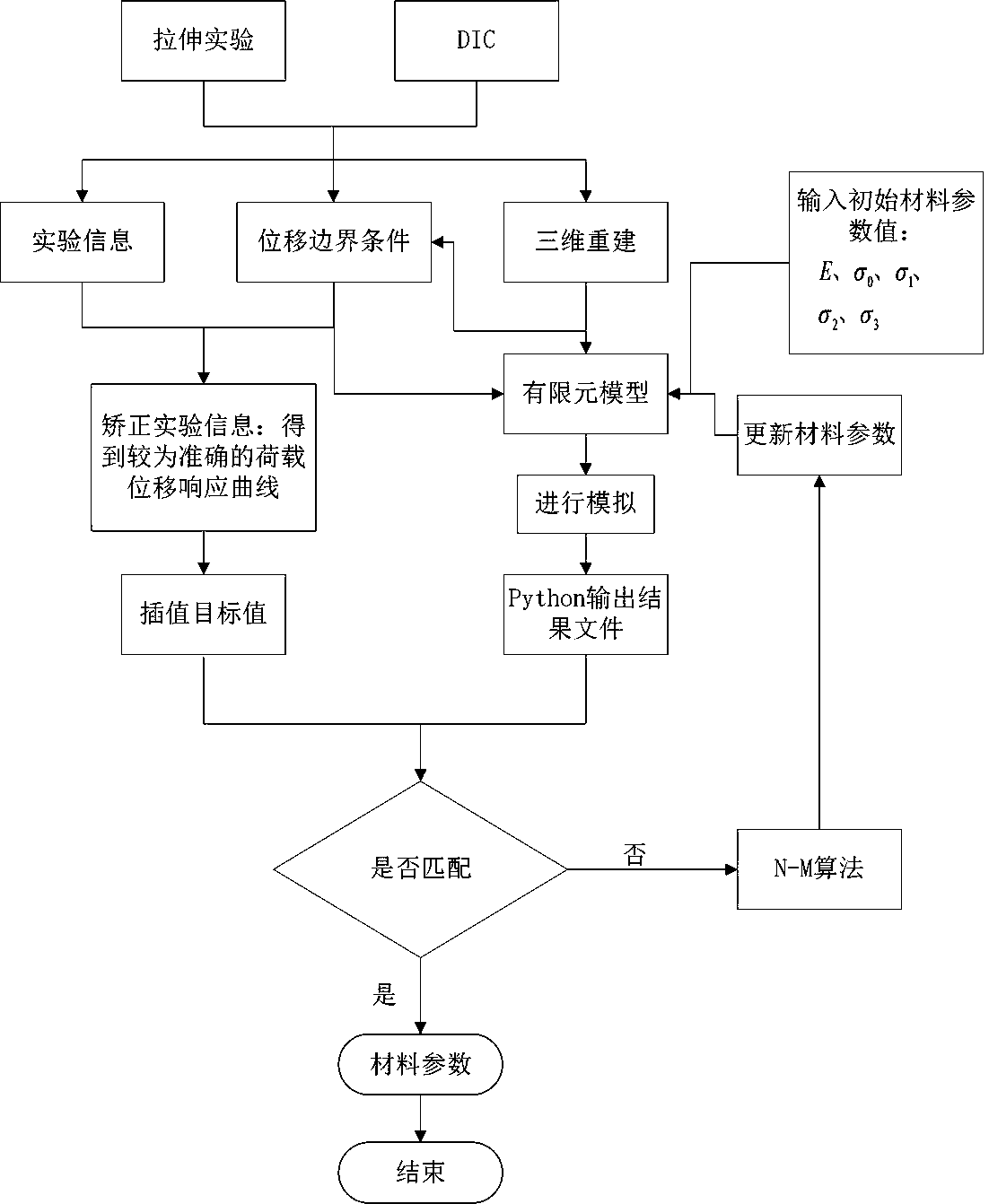

[0047] The method of obtaining material parameters based on DIC technology:

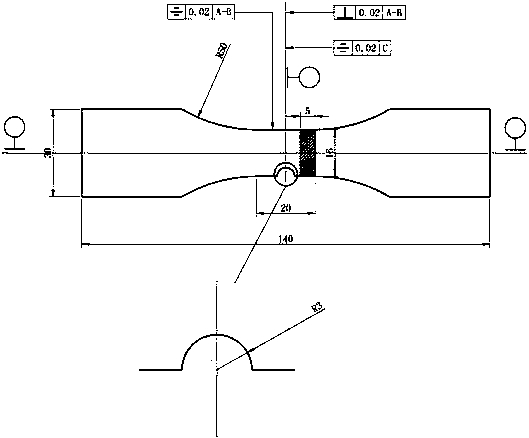

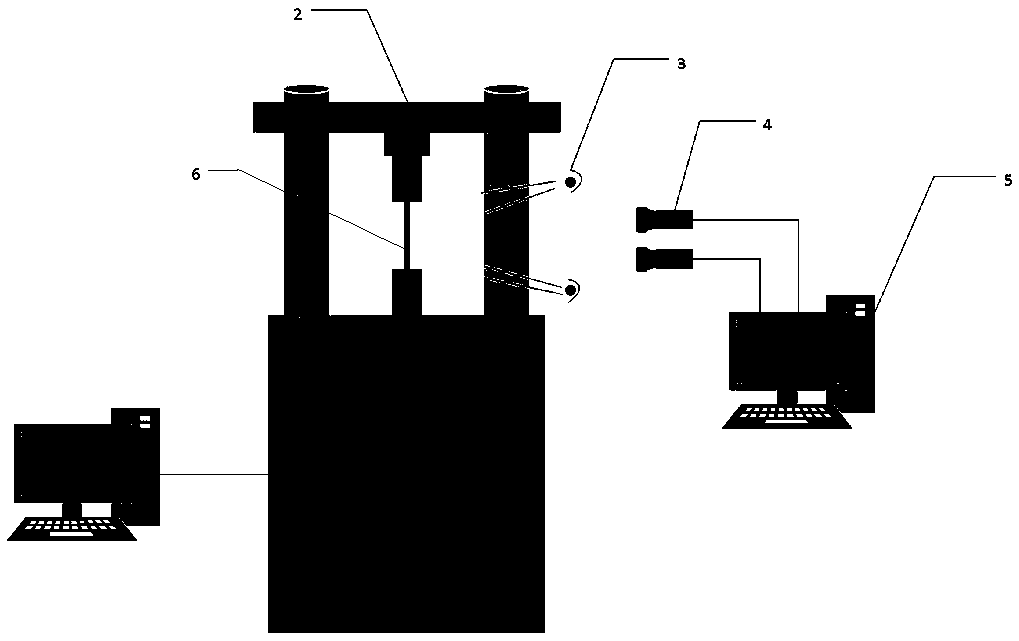

[0048] Step 1. Conduct a unilateral notch tensile test. The material is copper T2. The length of the gauge section is 20mm, the thickness is 5mm, and the width is 16mm. The enlarged picture of the notch on the right shows that the notch radius is 3mm. Tensile experiments were performed on an Instron 8872 electro-hydraulic servo testing machine. During the experiment, the digital image correlation method was used to observe and measure the gap area. The digital image correlation method is called Digital Image Correlation in English, referred to as DIC, and the DIC system includes: hardware equipment and software equipment. Hardware equipment includes: a pair of German Schneider Xenoplan1.4 / 23 lenses, a pair of Canadian PointGrey GRAS-20S4 / MCCCD digit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com