Multi-frequency hybrid wireless data read-write transmission device for heavy diesel engine machining production line

A heavy-duty diesel, wireless data technology, applied in instruments, sequence/logic controllers, program control, control/regulation systems, etc. problems with reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

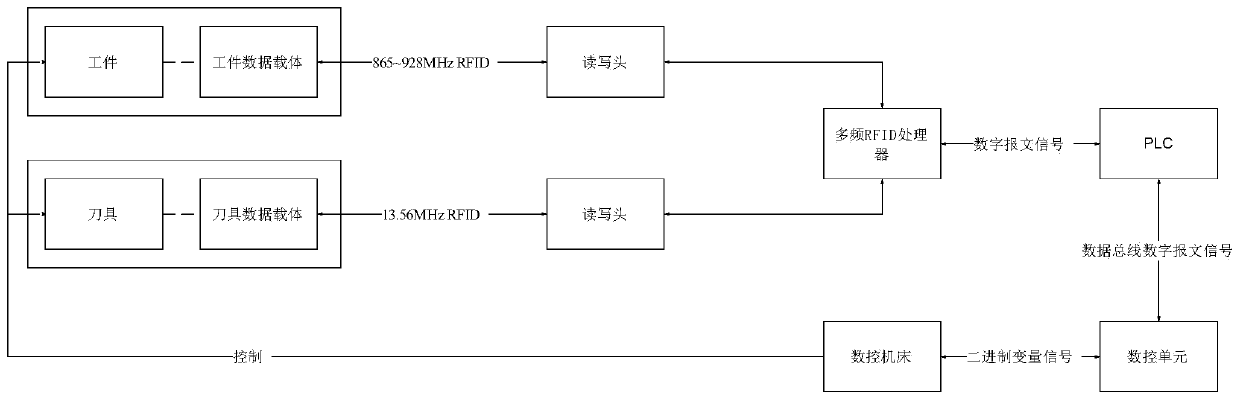

[0021] In this embodiment, a heavy-duty diesel engine machine plus production line multi-frequency hybrid wireless data read-write transmission device such as figure 1 As shown, the device consists of a CNC machine tool, a CNC unit, a PLC, a multi-frequency RFID processor, a read-write head and a data carrier;

[0022] The data carrier is installed on the workpiece or the cutting tool, and the coding information of the workpiece and the cutting tool is sent out in real time in the form of radio frequency signals of different frequencies; the read-write head installed on the station is used to receive the radio frequency signal of the workpiece data carrier , the read-write head installed on the machine tool is used to receive the radio frequency signal of the tool data carrier;

[0023] Among them, the radio frequency signal sent by the workpiece data carrier is 865MHZ-928MHZ, and the radio frequency signal sent by the tool data carrier is 13.56MHZ; the frequency of the read-w...

Embodiment 2

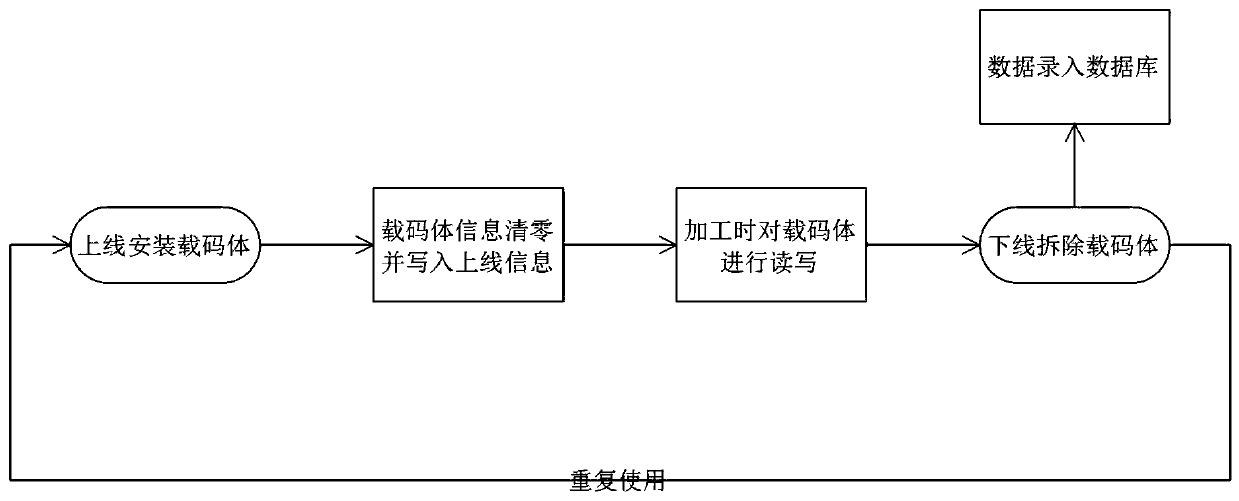

[0027] Such as figure 2 Before the workpiece goes online, it is necessary to install the screw-type data carrier on the workpiece, clear the information of the tag, and write the online information such as product model, serial number, date and time, equipment number and operator number.

[0028] When the workpiece enters the first machine tool, the UHF read-write head reads the code-carrying information of the workpiece and transmits it to the multi-frequency RFID processor. The multi-frequency RFID processor converts the radio frequency signal received by the read-write head into a digital message Signal, the PLC converts the digital message signal sent by the multi-frequency RFID processor into a bus digital message signal flow, and the numerical control unit converts the bus digital message signal flow transmitted by the PLC into a binary variable signal. The received binary variable signal associates the workpiece with the processing program, and calls the program to per...

Embodiment 3

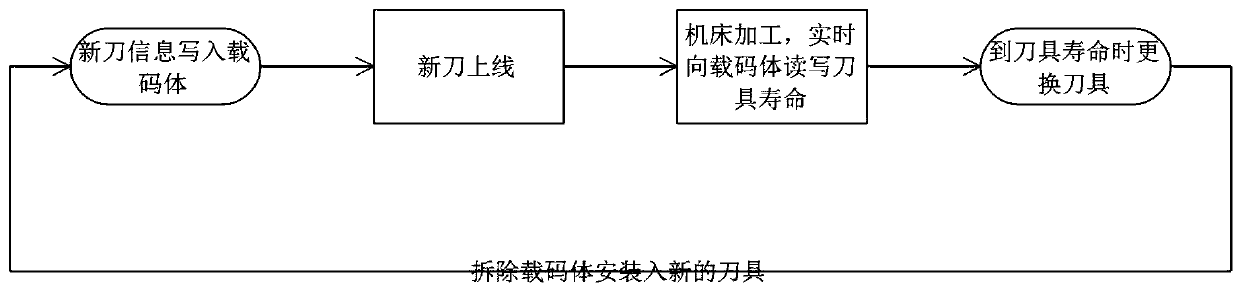

[0032] Such as image 3 Before the new tool goes online, it is necessary to install the φ10 data chip on the tool, clear the data information, and write the tool life, tool length and tool compensation information.

[0033] When a new tool enters the machine tool, the low-frequency read-write head reads the tool data chip information and transmits it to the multi-frequency RFID processor. The multi-frequency RFID processor converts the radio frequency signal received by the read-write head into a digital message signal, and the PLC will The digital message signal sent by the multi-frequency RFID processor is converted into a bus digital message signal flow, and the numerical control unit converts the bus digital message signal flow transmitted by the PLC into a binary variable signal. The signal adjusts the processing program variables according to the life, tool length and tool compensation information in the signal to carry out processing operations; the CNC unit automatical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com