Electromechanical integrated combined type quick switch

A fast switching and combined technology, applied in the field of switching, can solve the problems of useless energy consumption, unsatisfactory requirements, loud noise, etc., and achieve the effect of strong flow capacity and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

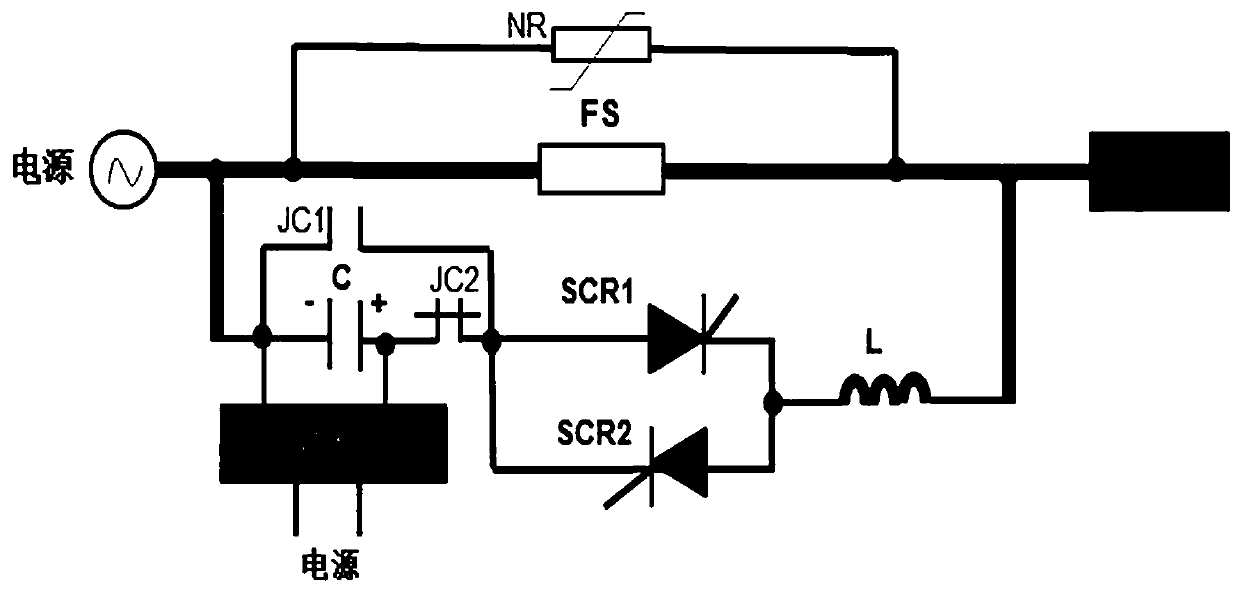

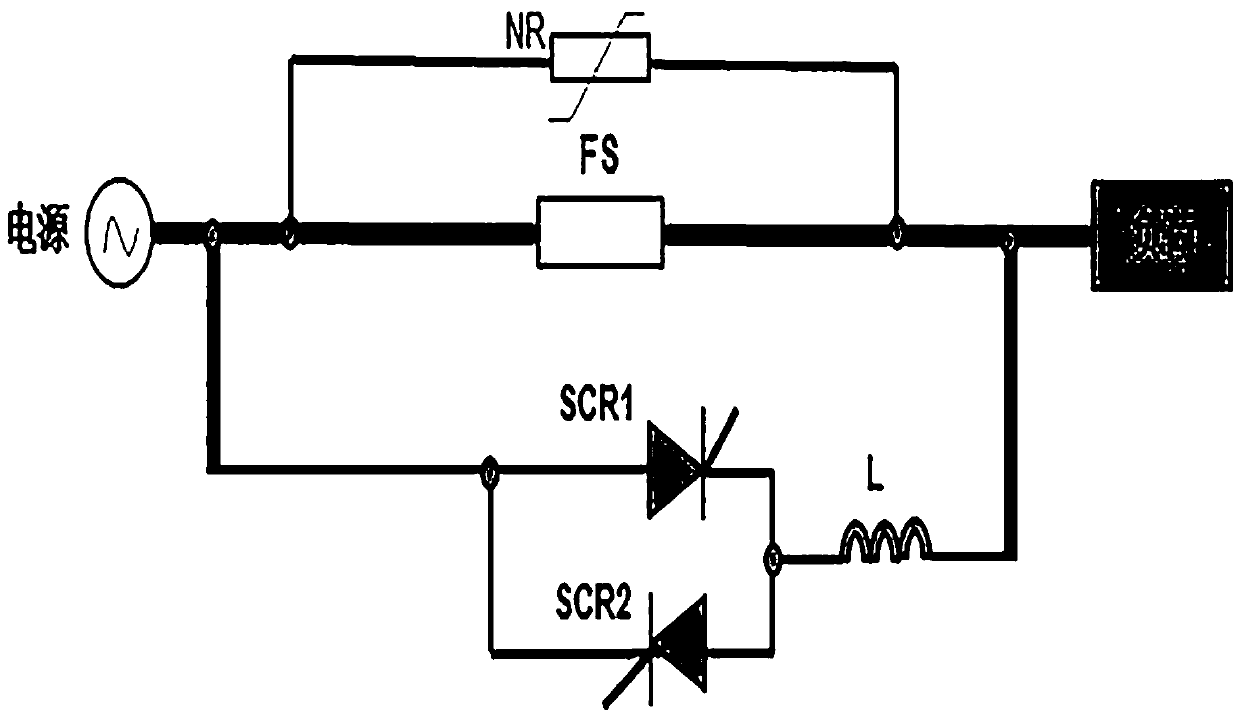

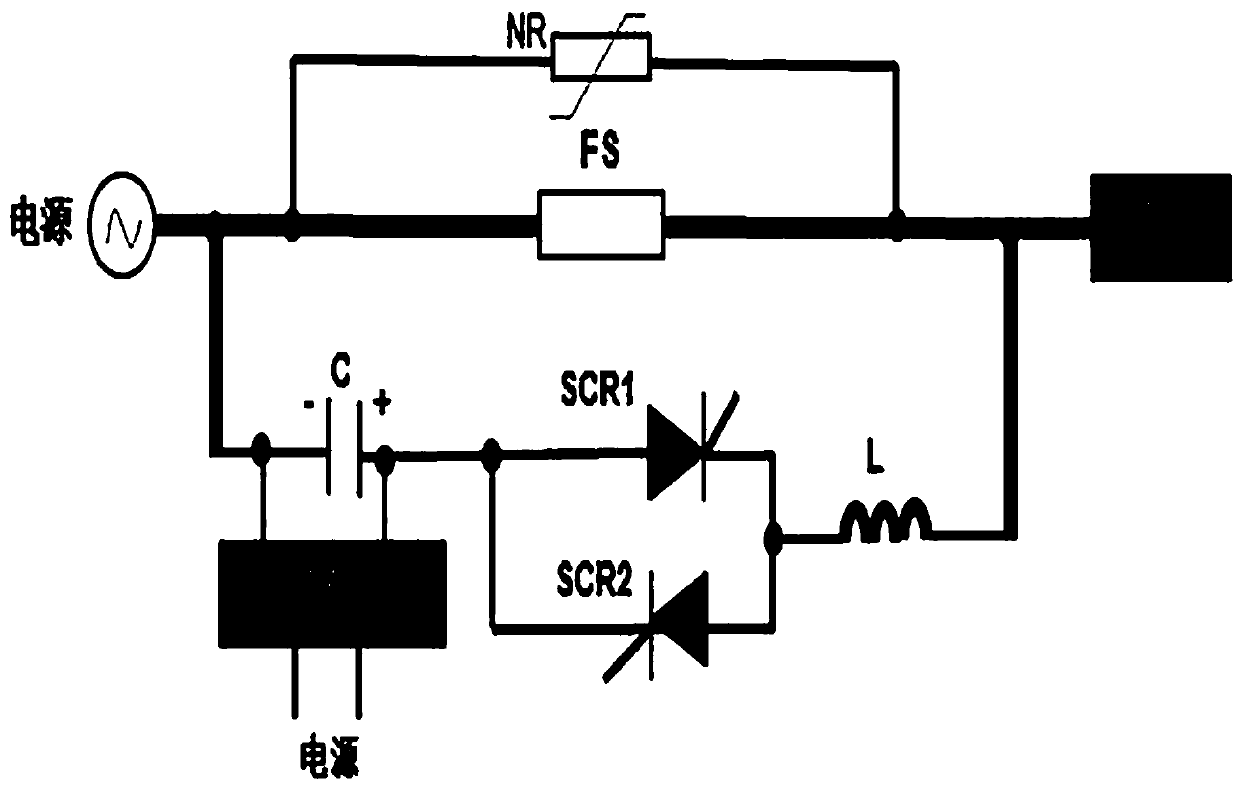

[0012] Such as figure 1 As shown, in this embodiment, the electromechanical combined fast switch is mainly composed of mechanical eddy current driven vacuum fast switch, power electronic switch, artificial zero-crossing arc extinguishing unit, switching unit and other parts. figure 1 shown. in,

[0013] FS: mechanical eddy current driven vacuum fast switch, main switch;

[0014] SCR1, SCR2: Power electronic switches, used to assist the main switch to turn on and turn off quickly;

[0015] C: Energy storage capacitor, used to generate artificial zero-crossing current, and assist the main switch to turn off quickly;

[0016] L: Current-limiting reactor, used to limit the rate of change of current in the circuit (di / dt);

[0017] JC1∼2: AC contactor switching main contact, used to switch the working mode of power electronic switch;

[0018] NR: Zinc oxide nonlinear resistor, overvoltage protection;

[0019] CDD: charging unit, used to charge the energy storage capacitor.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com