Pressing type make-up pen cap and manufacturing method thereof

A manufacturing method and a cosmetic pen technology are applied in the directions of packaging cosmetics, cosmetic powder containers, dressing containers, etc., which can solve problems such as adverse effects of long-term storage of cosmetics, bacterial contamination, poor sealing, etc., and achieve inhibition of bacterial growth and processing efficiency. High, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

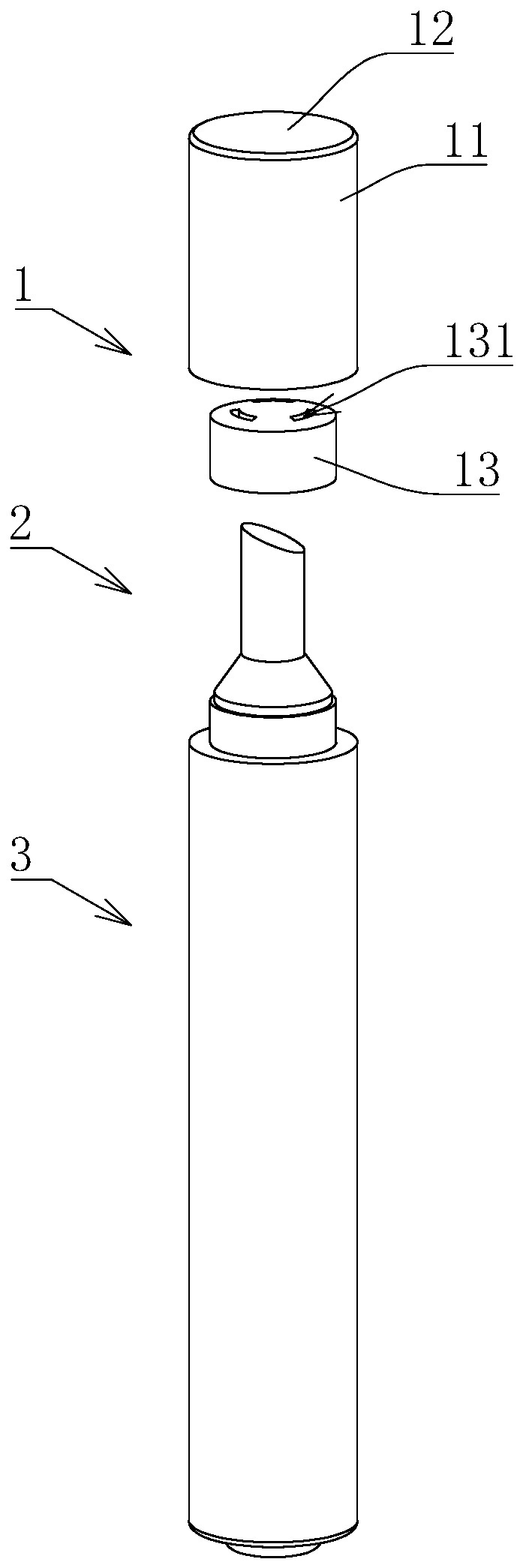

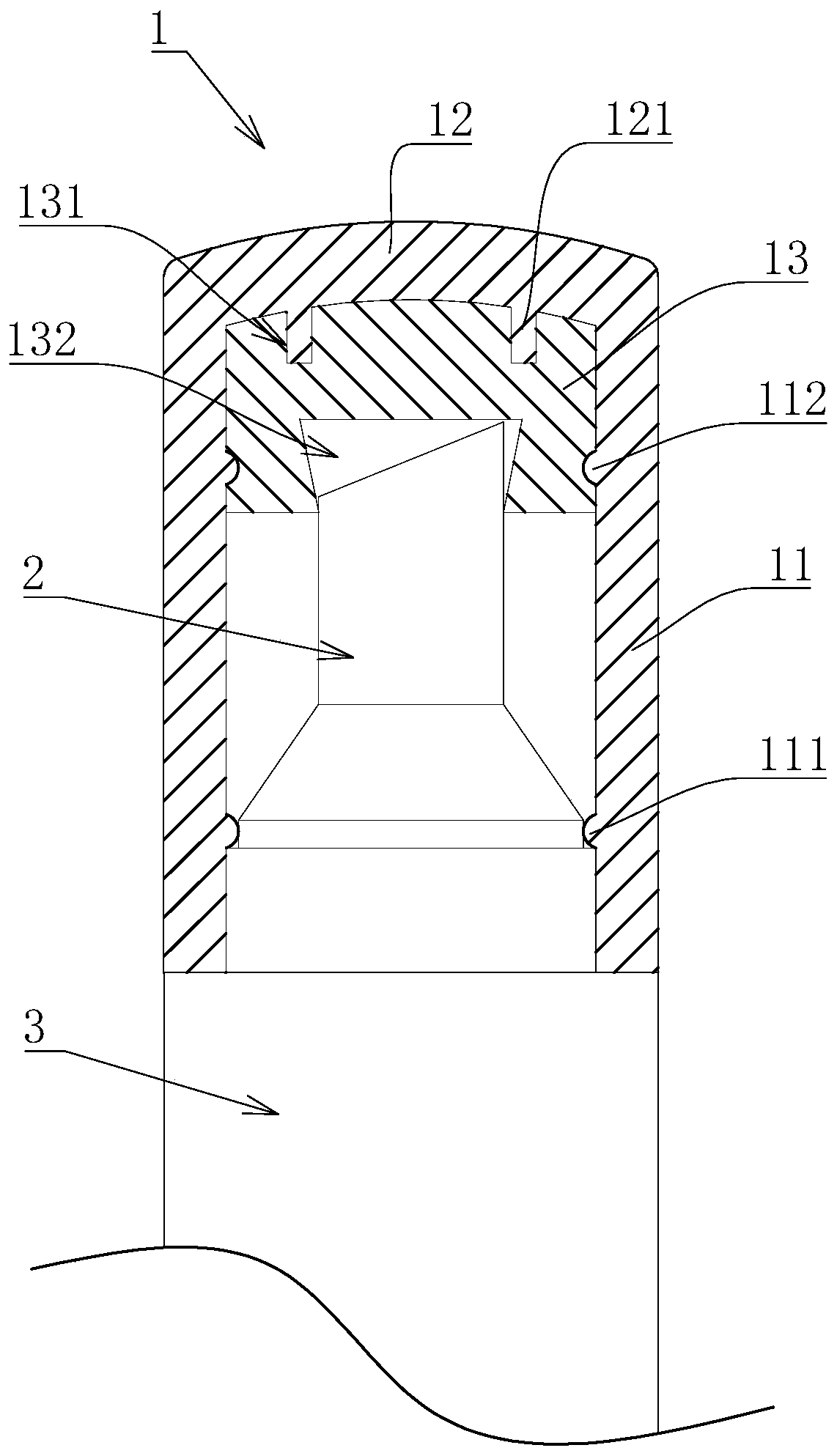

[0052] A push-type makeup pen cap, refer to figure 1 and figure 2 , which includes a body 11 for cooperating with the cosmetic pen holder 3 to protect the nib 2 at the end of the pen holder 3 , the body 11 is in the shape of a hollow tube, and one end of the body 11 is provided with an end plate 12 . The end plate 12 is an arc-shaped plate concaved away from the opening of the main body 11 .

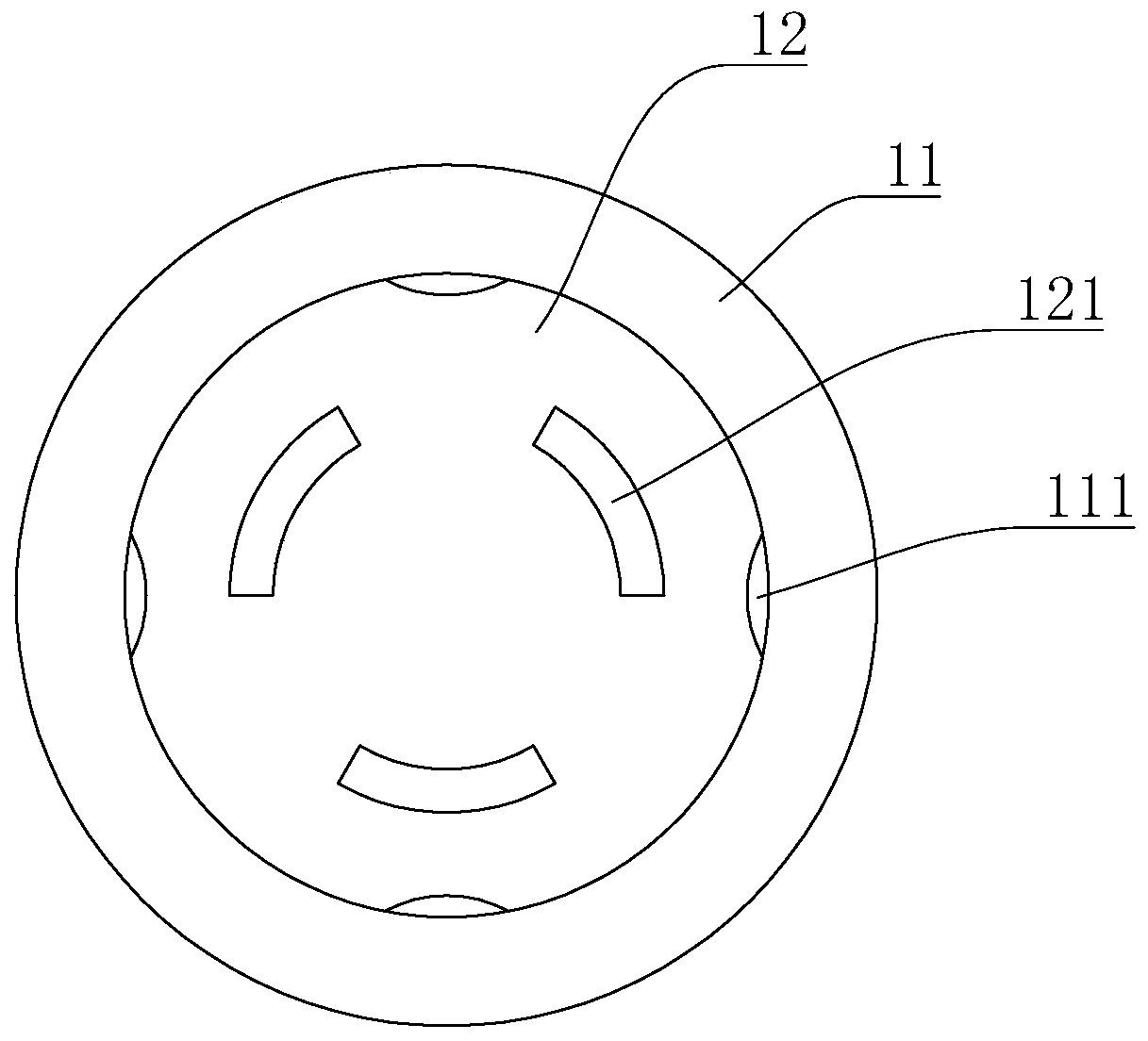

[0053] refer to figure 2 and image 3 , the end plate 12 is provided with several positioning blocks 121 , and the positioning blocks 121 are located in the cavity of the main body 11 . In this embodiment, the positioning blocks 121 are arc-shaped blocks with a rounded angle of 60°, and there are three positioning blocks at equal intervals around the axis of the body 11 .

[0054] refer to figure 1 and figure 2 , the body 11 is provided with an elastic cork 13 attached to the end plate 12, and the elastic cork 13 is made of food-grade silicone rubber, which is soft and non-toxic...

Embodiment 2

[0071] A push-type cosmetic pencil cap, the difference between this embodiment and embodiment 1 is only:

[0072] During the molding process of the pen cap, 2wt% of 600-mesh tourmaline powder was added to the molten injection plastic; in the hot-pressing step, the hot-pressing temperature was 160°C, the hot-pressing pressure was 8 MPa, and the hot-pressing time was 7 minutes.

Embodiment 3

[0074] A push-type cosmetic pencil cap, the difference between this embodiment and embodiment 1 is only:

[0075] During the molding process of the pen cap, 3wt% of 325-mesh tourmaline powder was added to the molten injection plastic; in the hot-pressing step, the hot-pressing temperature was 180°C, the hot-pressing pressure was 10MPa, and the hot-pressing time was 5min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com