Modular automatic cell culture system and method

A culture system and culture method technology, applied in tissue cell/virus culture devices, biochemical equipment and methods, biochemical instruments, etc., can solve the problems of high use cost, limited production scale benefit, long cycle, etc., to reduce the cost of facilities Effects of construction cost, effective cost optimization, and industrial scale expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

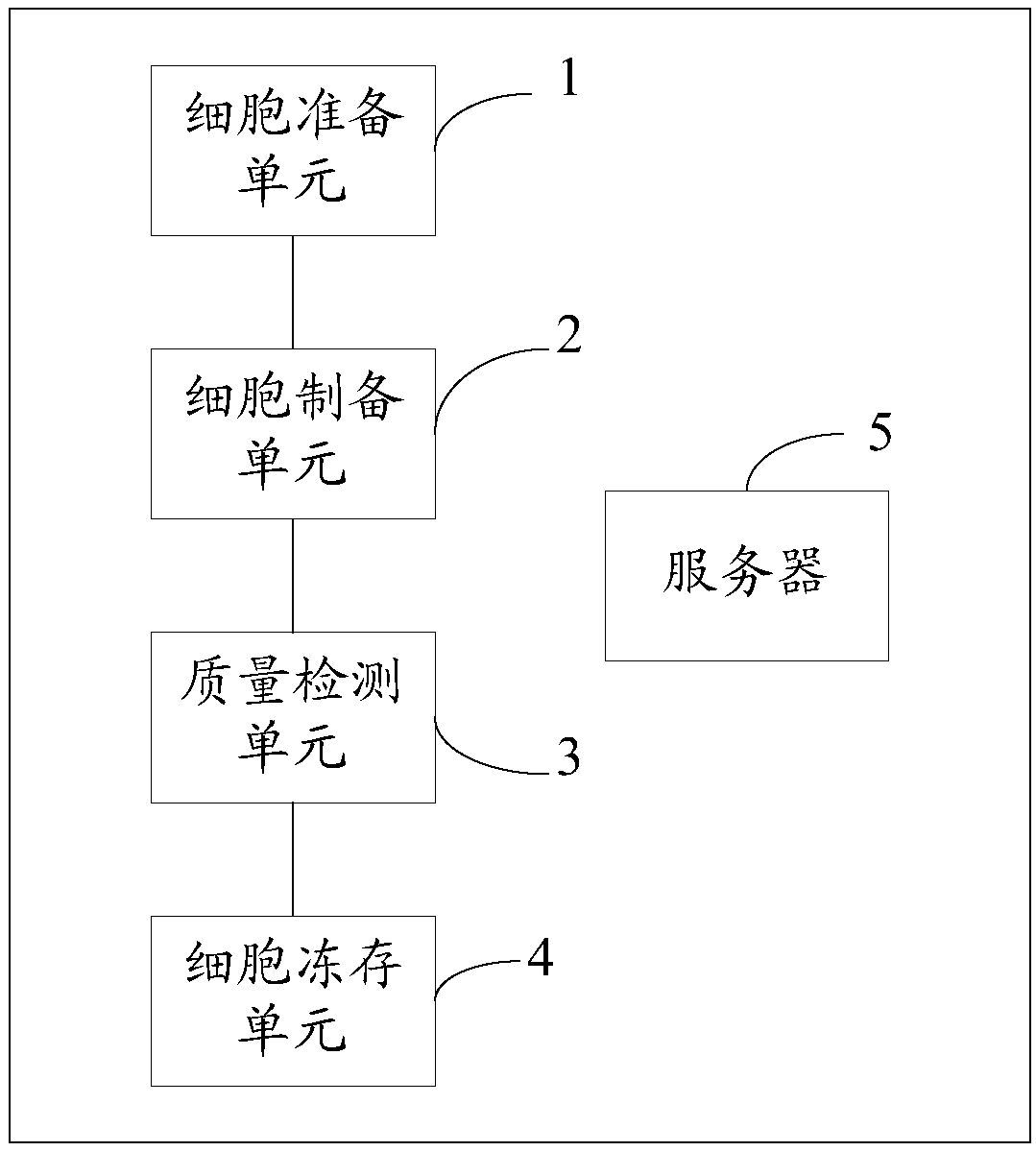

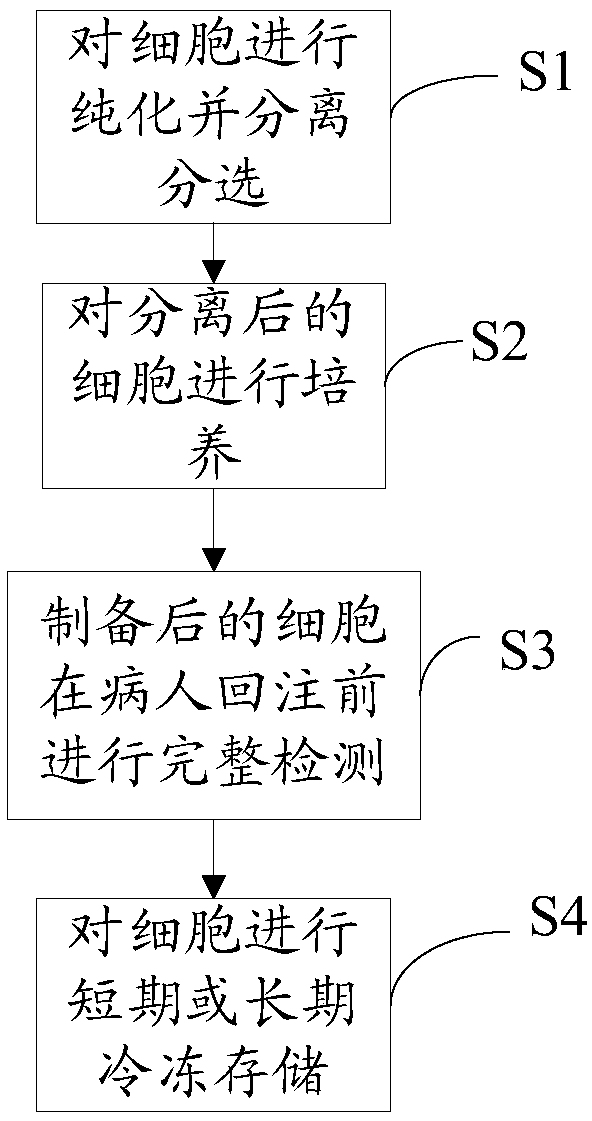

[0033] Such as Figure 1~2 In the specific embodiment shown, a modular automatic cell culture system provided by this embodiment can be used in the process of cell culture, modular culture, realize the modularization of the cell culture process, reduce the cost of facility construction, and automatically cultivate Cells, forming effective cost optimization, industrial scale expansion and economic benefits brought about by large-scale cell production.

[0034] Such as figure 1 As shown, this embodiment provides a modular automatic cell culture system, which includes a cell preparation unit 1 , a cell preparation unit 2 , a quality inspection unit 3 and a cell cryopreservation unit 4 .

[0035] Cell preparation unit 1 is used for sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com