Semiconductor component with first temperature measuring element and method for determining a current flowing through the semiconductor component

A temperature measurement and semiconductor technology, applied in the field of vehicle control devices, to achieve the effect of reducing consumption, cost saving, and reducing effective cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

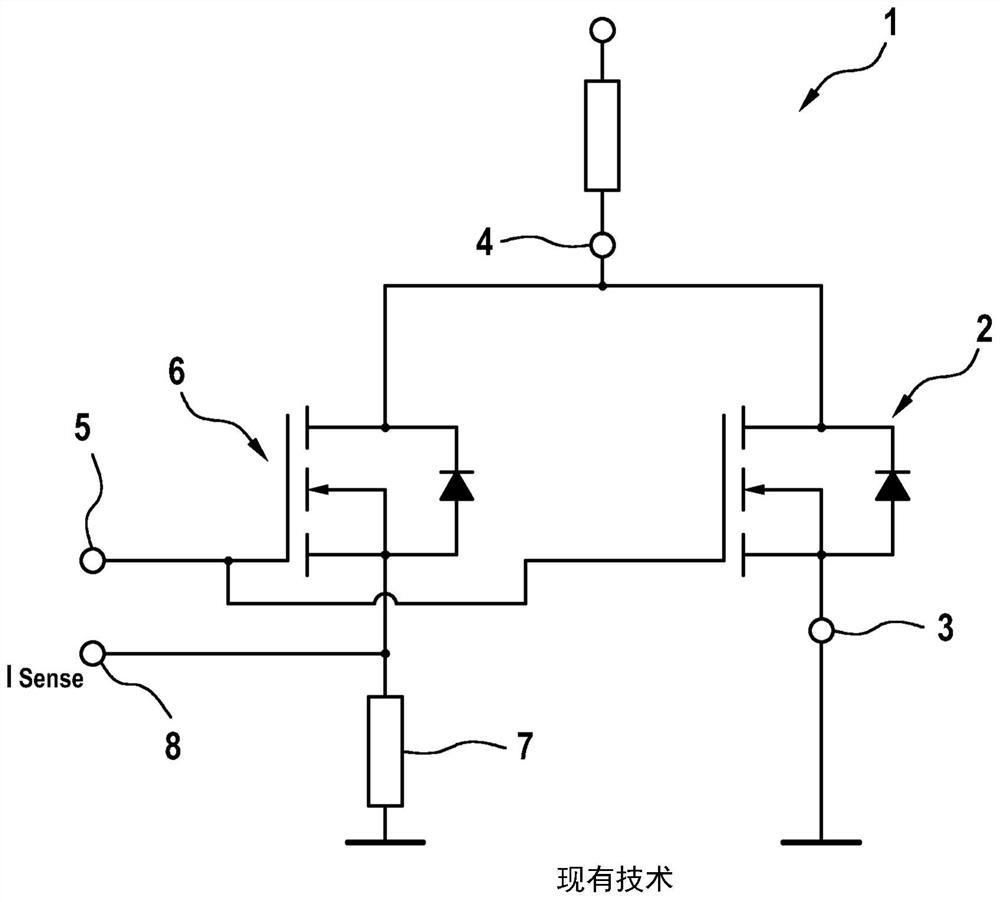

[0039] first in figure 1 A possibility according to the prior art for ascertaining the current flowing through a semiconductor component 10 in the form of a current sensor with divided cells is shown in . A main FET (Field Effect Transistor) 2 is shown in the right part of the figure. The main FET is connected as usual with a source contact 3 , a drain contact 4 and a gate contact 5 . Measuring FET 6 is shown in the left region of the figure. The measuring FET is connected in parallel with the main FET 1 and consists of some divided cells, but otherwise identical to those of the main FET 1 . The separated cells are used as current mirrors. The current I can be read at the current measuring point 8 with the aid of an external resistor 7 Sense , which allows a direct deduction of the current flowing through main FET 1. However, resistor 7 can limit the dynamics and accuracy of the current measurement. Furthermore, in solutions known from the prior art, temperature sensors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com