Environment-friendly closed-fit wearable wool worsted fabric and processing method

A processing method and technology of worsted fabrics, applied in textiles, textiles, papermaking, yarns, etc., can solve the problems that synthetic fibers are not suitable for spinning, and cannot solve the problem of itching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

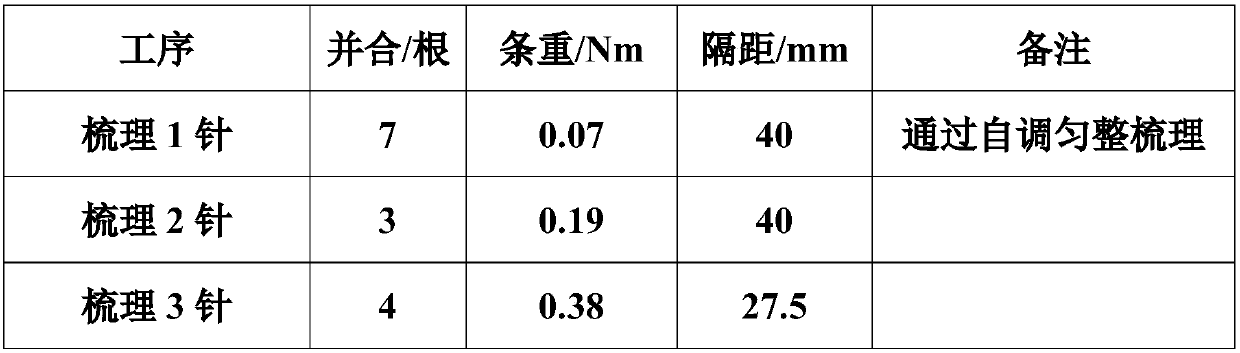

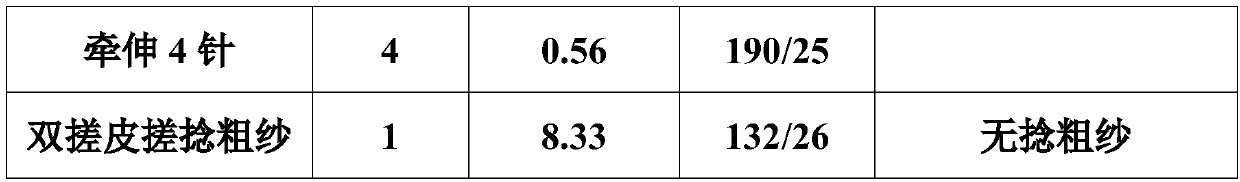

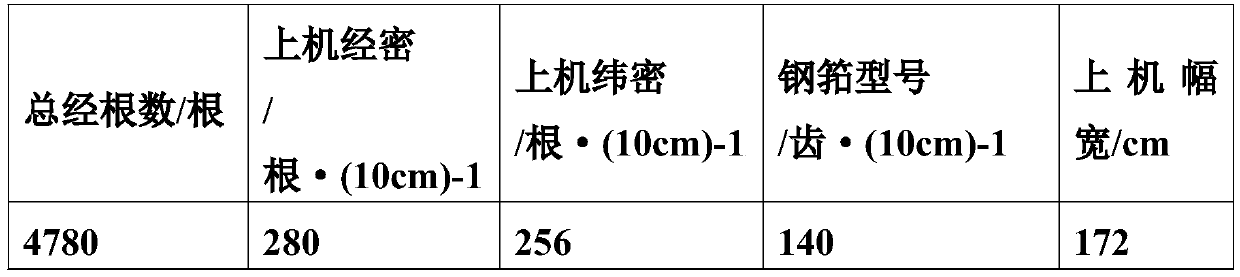

Method used

Image

Examples

Embodiment 1

[0026] An environment-friendly processing method of wearable wool worsted fabric, the processing method includes six steps, the first step is raw material selection, the second step is raw material ratio, the third step is dyeing process, the fourth step is spinning process, and the fifth step is The first step is the weaving process, and the sixth step is the post-finishing process.

Embodiment 2

[0028] The processing method of a kind of environment-friendly close-fitting wearable wool worsted fabric described in Example 1, the raw material selection of the first step includes (1) Basolan wool (18.5 μm BASOLAN), in order to ensure the environment-friendly close-fitting wearable wool fine Textiles are easy to care for and comfortable next to the skin. It is necessary to use environmentally friendly processing methods to pre-treat the wool fiber so that the wool fiber does not produce directional movement during the wearing process, and at the same time it does not cause itching when worn next to the skin; ① use organic chlorinated agents ( BASOLAN88) to remove wool scales, reduce the damage to wool fibers in the reprocessing process, and minimize the environmental pollution in the processing process to meet the emission requirements; All natural characteristics except for directional movement; ③Making wool fiber have good dyeing performance and bright colors;

[0029] ⑵...

Embodiment 3

[0039] The processing method of a kind of environment-friendly close-fitting and wearable worsted fabric described in Example 1, the raw material ratio in the second step is obtained through comparative experiments of various experimental schemes, after comprehensive consideration of raw material cost, product style and close-fitting wearable Based on the wearing performance of the product, the raw material ratio is determined as follows: 18.5 μm wool (BASOLAN) 65%, 2D cupro fiber 20%, 3D graphene composite fiber (nylon matrix) 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com