Production method for functional nanofiber yarns

A nanofiber and functional technology is applied in the processing field of one-step preparation of functional nanofiber yarn, which can solve the problems of complex, uneven, and tedious finishing of processing procedures, so as to reduce processing procedures, improve production efficiency, and reduce tedious steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

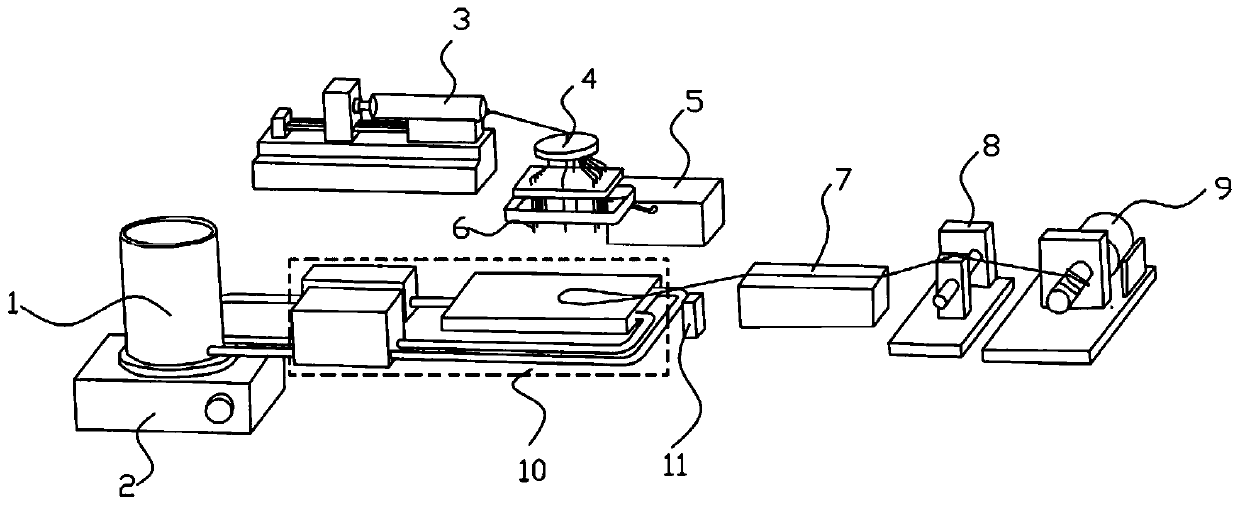

[0024] see figure 1 , figure 1 It is a process flow diagram of a preparation method of a functional nanofiber yarn of the present invention. Such as figure 1 As shown, the specific process steps are as follows:

[0025] (1) Mix the functional nanoparticles and the dispersant evenly, add them to the prepared Pingpinga O aqueous solution, stir it on a magnetic stirrer, and then perform ultrasonic treatment on it to prepare a functional nanoparticle dispersion, which is then Pour it into the beaker 1, and the magnetic stirrer 2 is always in working condition during the spinning process. The functional nanoparticles include chitosan, nano-titanium dioxide, nano-silver, nano-copper, cerium oxide, etc. Due to the high free energy on the surface of the nanoparticles, agglomeration will occur when the nanoparticles are dispersed in the bath. The effect of adding a dispersant in the bath is to reduce the agglomeration of the nanoparticles in the bath and improve the Stability in b...

Embodiment 1

[0030] This implementation case shows a preparation method of a functional nanofiber yarn (chitosan / polyamide 6 functional nanofiber yarn) according to the following steps:

[0031](1) Prepare a mixed dispersant with Span-80 and Tween-80 in a mass ratio of 3:7, then add chitosan nanoparticle powder into the dispersant and mix evenly to ensure that the surface of chitosan nanoparticles is covered. Dispersant is fully wrapped; Then add 0.5wt% Pingpinga O aqueous solution to form bath liquid, wherein the mass fraction of mixed type dispersant in bath liquid is 0.2%, and the mass fraction of chitosan nanoparticle is 0.4%; In magnetic stirrer Preliminary dispersion under the action of 30min stirring time, followed by ultrasonic treatment, ultrasonic time 50min, to obtain a uniformly dispersed spinning bath.

[0032] (2) Add the polyamide 6 solution with a mass fraction of 25% into a 20ml syringe, control the flow rate of the solution through a flow pump, which is 1ml / h, and the sol...

Embodiment 2

[0035] This implementation case shows a preparation method of functional nanofiber yarn (chitosan / polyacrylonitrile functional nanofiber yarn) according to the following steps:

[0036] (1) The preparation process is the same as step (1) of Example 1.

[0037] (2) Add the polyacrylonitrile solution with a mass fraction of 8% into a 20ml syringe, and control the flow rate of the solution by a flow pump, which is 7ml / h. Nanofibers are formed under the action of the glass rod and deposited on the surface of the bath. After the nanofibers are deposited on the bath, the chitosan nanoparticles are quickly adsorbed on the surface of the nanofibers to form functional nanofibers. Under the guidance of the glass rod, the nanofiber bundles Through the yarn guide hook, the drying device, the yarn guide traverse device in turn, and finally wind the nanofiber yarn onto the bobbin through the winding device; then turn on the reverse water bath system to realize the circulation of the bath li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com