An ultra-thin infrared collimator based on fly-eye lens

A fly-eye lens and collimator technology, which is applied in the field of infrared optics, can solve the problems of large size, difficulty in realizing infrared collimator, and large volume of target source simulation device, and achieve the effect of shortening the focal length of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

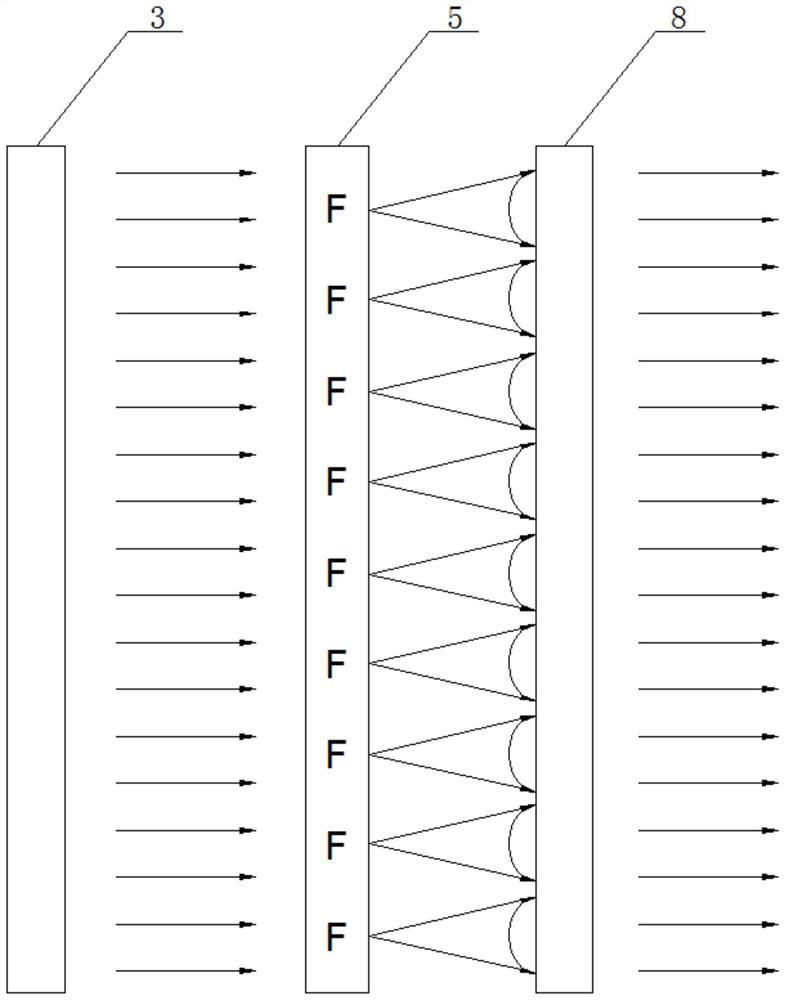

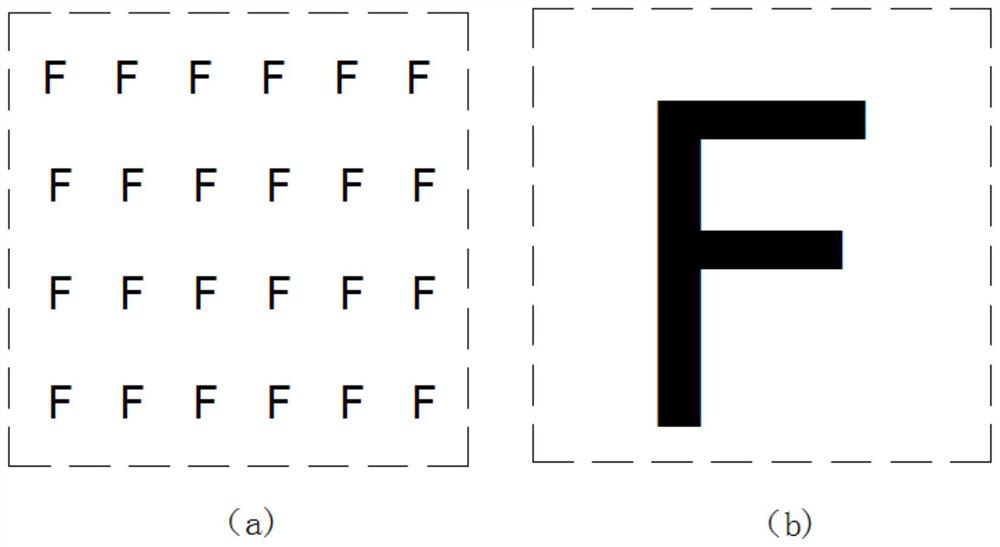

[0025] Specific implementation mode one: as Figure 1-Figure 9 As shown, this embodiment discloses an ultra-thin infrared collimator based on a fly-eye lens, including a light source system, a target lens assembly, a fly-eye lens assembly, a box assembly and an adjustment pad 7, and the box assembly includes a box 4 , a rear cover 1 and a front cover 10, a fly eye lens assembly, a target lens assembly and a light source system are sequentially installed in the box body 4 from front to back, and an adjustment device is tightly installed between the fly eye lens assembly and the target lens assembly Pad 7, the front end of the box body 4 is fixedly equipped with a front cover plate 10, the middle part of the front cover plate 10 is provided with an infrared output window 2, and the rear end of the box body 4 is fixedly equipped with a rear cover plate 1;

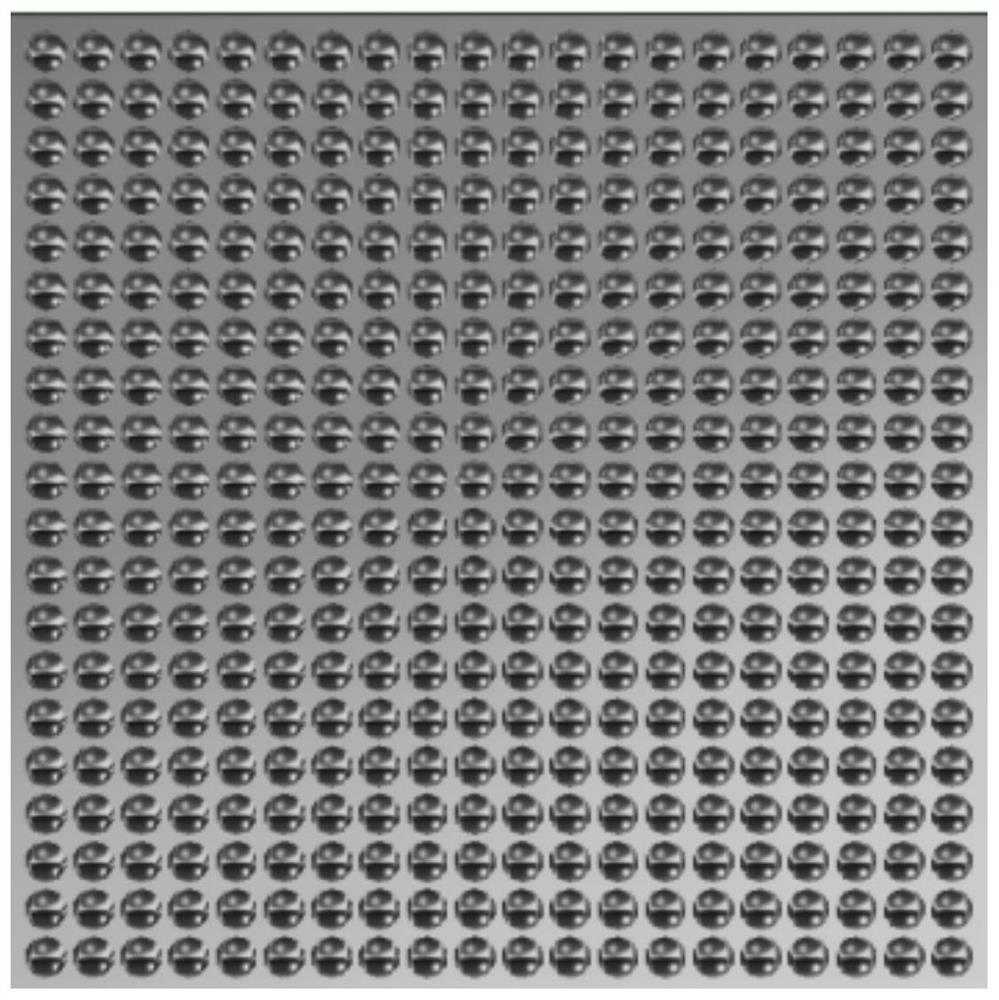

[0026] The fly-eye lens 8 in the fly-eye lens assembly is composed of several small lens units in a rectangular array. The t...

specific Embodiment approach 2

[0032] Specific implementation mode two: as Figure 7 As shown, this embodiment is a further description of Embodiment 1. The fly-eye lens assembly includes a fly-eye lens 8, a support seat 6, a partition 11 and a rubber pre-tightening pad 9; the fly-eye lens 8 is fixed In the supporting base 6, the partition 11 is fixed on the front end of the fly-eye lens 8 and the supporting base 6, and the rubber pre-tightening pad 9 is tightly installed between the supporting base 6 and the front cover 10, and the dividing plate 11 The middle part is provided with a light transmission port 12 having the same size as the infrared output window 2 of the front cover 10, and the rubber pre-tightening pad 9 is ring-shaped, and the middle part is provided with a light output port.

specific Embodiment approach 3

[0033] Specific implementation mode three: as Figure 7 As shown, this embodiment is a further description of the first embodiment, the target lens assembly includes the target lens 5 and the second support seat 13; the target lens 5 is fixedly installed in the second support seat 13, and the support Seat two 13 is fixedly connected with casing 4 (by hexagon socket head screw).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com