High-power-density COB device

A high power density, device technology, applied in the direction of electric solid state devices, semiconductor devices, electrical components, etc., can solve the problems of not meeting the market demand, small installation area, etc., achieve small installation area, improve power density, and ensure light output efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

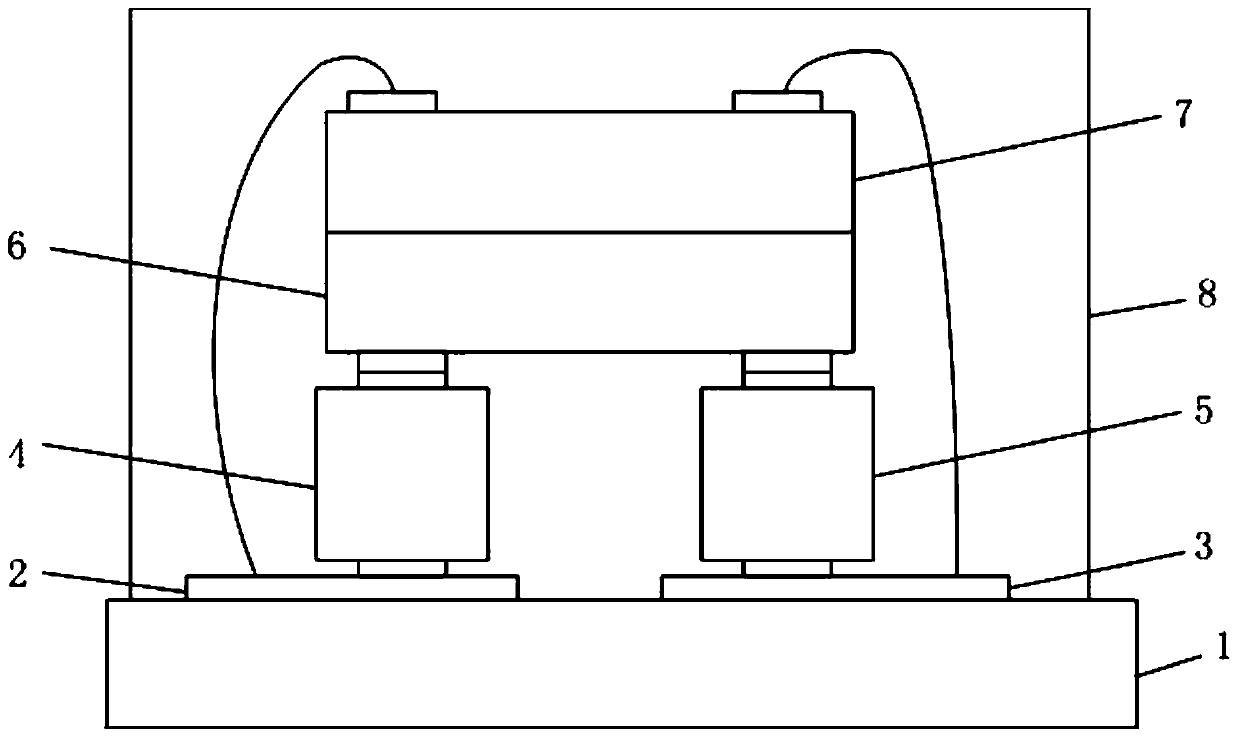

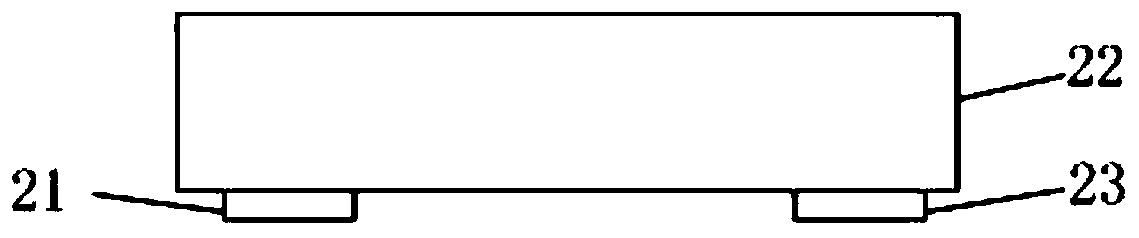

[0022] see figure 1 A high power density COB device provided by the present invention includes a substrate 1 , several laminated structures disposed on the substrate 1 , and an encapsulation layer 8 covering the laminated structures.

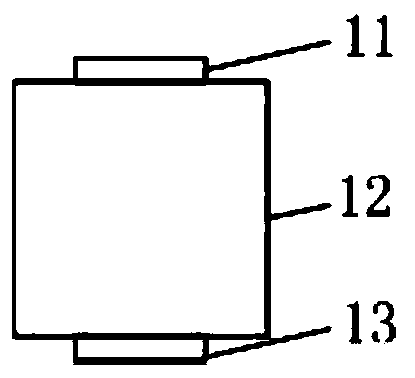

[0023] The laminated structure of the present invention includes a first pad 2 , a second pad 3 , a first vertical chip 4 , a second vertical chip 5 , a flip chip 6 and a front chip 7 .

[0024] The substrate 1 of the present invention is used to install other structures of COB devices, and it can be a ceramic substrate or a metal substrate, and the type of the substrate 1 is selected according to actual needs.

[0025] The first pad 2 and the second pad 3 of the present invention are loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com