High-temperature-resistant flexible fireproof cable intermediate joint

An intermediate joint, fireproof cable technology, applied in the direction of cable joints, connection insulation, etc., can solve the problems of low temperature resistance, easy water ingress, and can not achieve the purpose of fire prevention, and achieves improved flame retardant performance, high temperature resistance level, Avoid the effect of short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

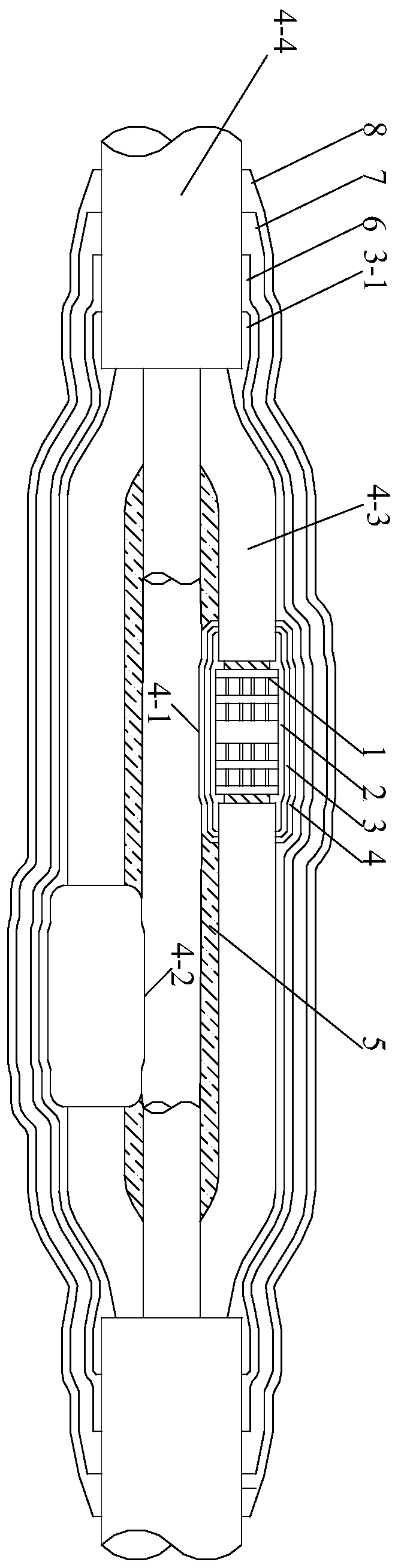

[0027] like figure 1 As shown, a high-temperature-resistant flexible fireproof cable intermediate joint, which includes an intermediate joint body 4-1 for connecting multi-core cable insulated cores 4-3, the intermediate joint body 4-1 includes a conductor connecting pipe 1, a conductor connecting pipe 1 is copper or aluminum, the size meets the requirements of GB / T 14315, and the material of the copper connecting pipe is not less than No. 3 copper T3, GT type, tin-plated according to the requirements of GB / T 5231; No less than No. 2 industrial pure aluminum L2, GL type, the surface is treated or polished by chemical methods. Conductor connecting tube 1 is wrapped with silicone rubber self-adhesive tape 2, ceramic refractory mica tape 3 and silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com