Rare earth permanent magnet disc type motor adopting outer interlayer cooling cavity for heat dissipation

A rare-earth permanent magnet and cooling cavity technology, which is applied in the direction of cooling/ventilation device, magnetic circuit shape/style/structure, magnetic circuit, etc., can solve the problem of affecting the waterproof and dustproof effect of the motor, increasing the volume and weight of the motor, and reducing the use of the motor Life and other issues, to achieve the effect of saving volume and weight, improving waterproof and dustproof level, and accelerating flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

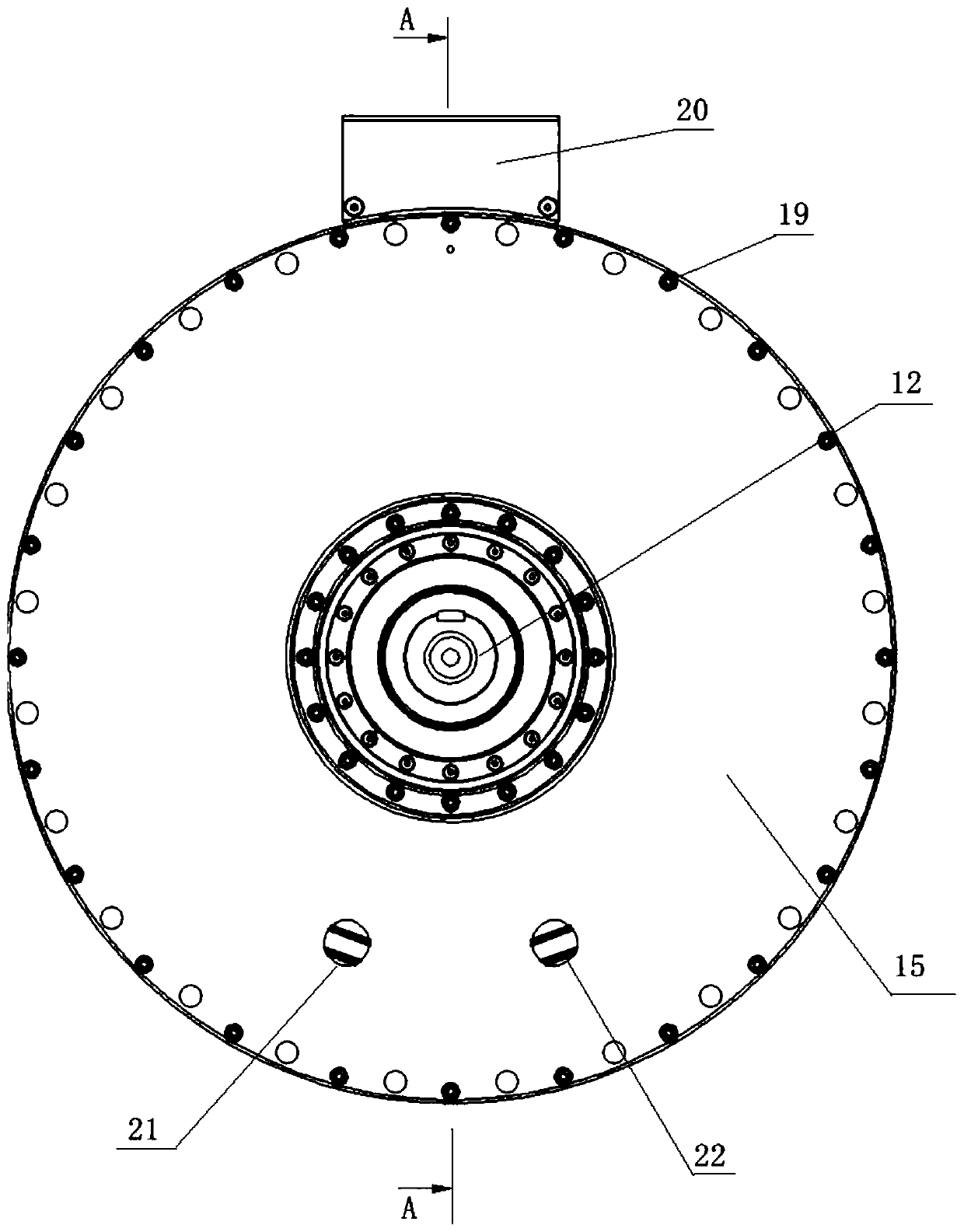

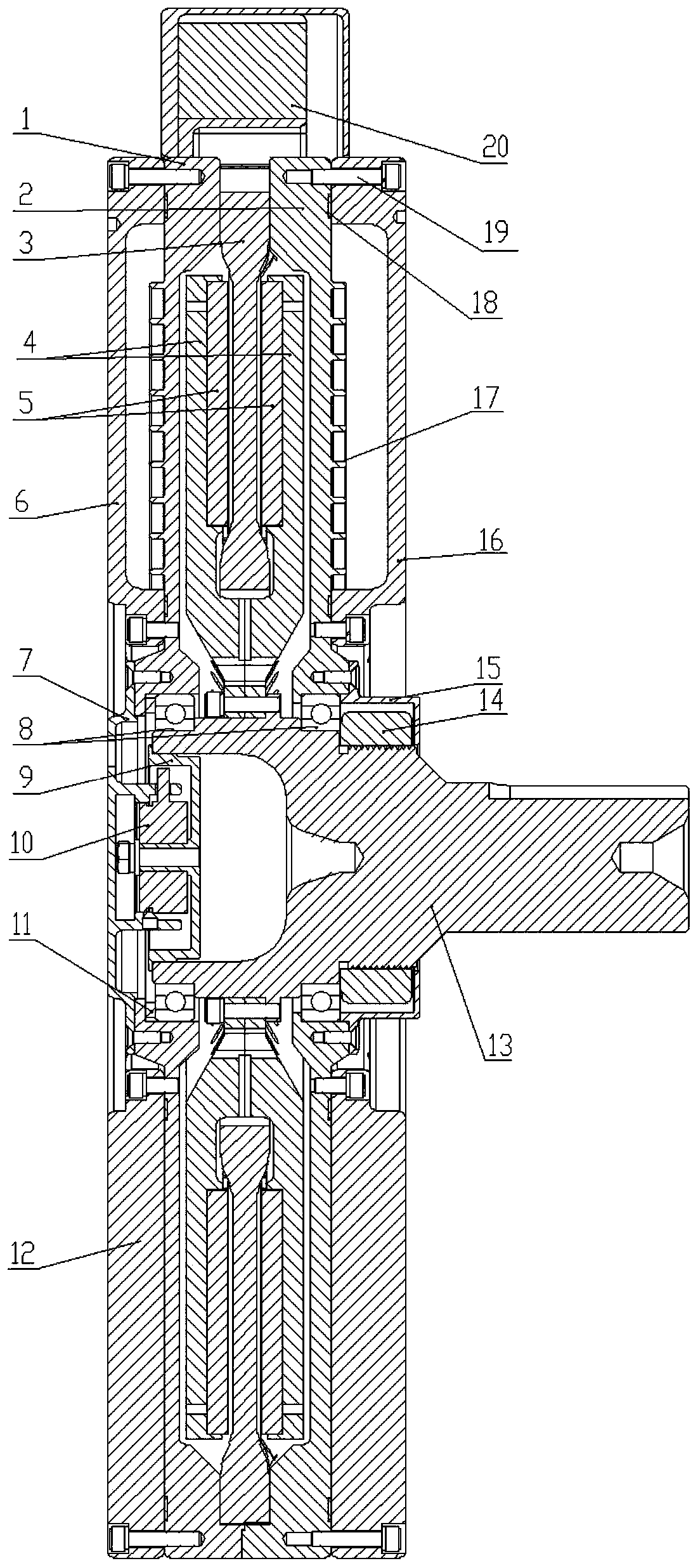

[0020] like Figure 1-2 As shown, the present invention includes a stator disk 3, two rotor disks 4 and two cooling shells, the outer edge ends of the stator disk 3 are fixedly connected with the two cooling shells, and the end faces of the stator disk 3 and the two cooling shells have Install the installation cavity of the rotor disk 4, the inner ring of the cooling shell is connected with the rotating shaft 13 through the bearing 8, and the two rotor disks 4 are symmetrically installed in the installation cavity on both sides of the stator disk 3, and the inner ring of the rotor 4 is connected to the rotating shaft 13 Fixedly connected, two rotor disks 4 near the end of the stator disk 3 are arranged in a ring array with several rare earth permanent magnet blocks 5, and the rotor disk 4 is provided with installation grooves for installing the rare earth permanent magnet blocks 5, and the rare earth permanent magnet blocks 5 are installed with the Slot bonding connection, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com