A steel pipe welding machine that is convenient to drag and straighten

A technology for welding machines and welding racks, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increased cost and poor connection, and achieve increased speed, improved work efficiency, and increased transportation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

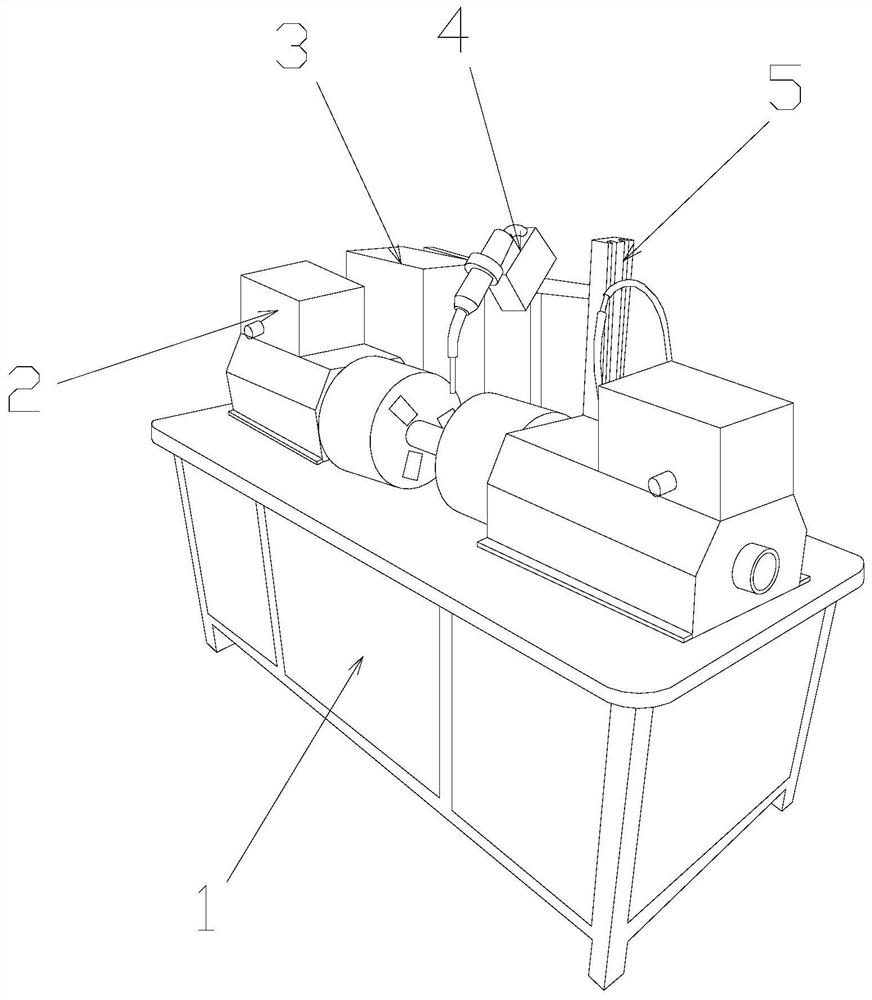

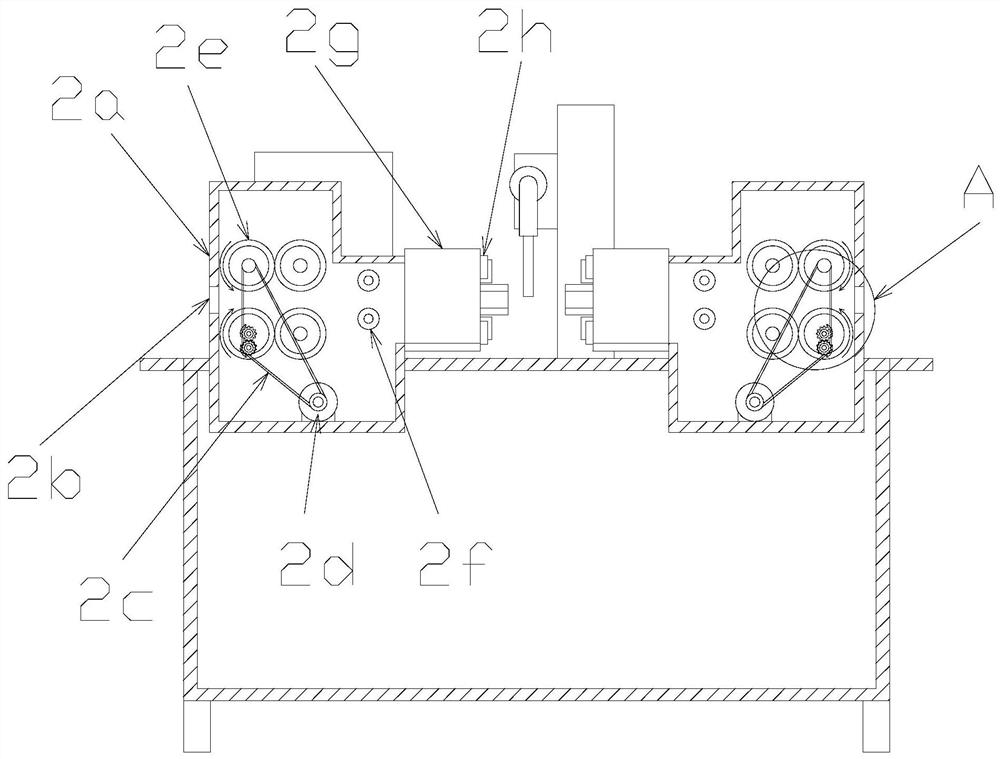

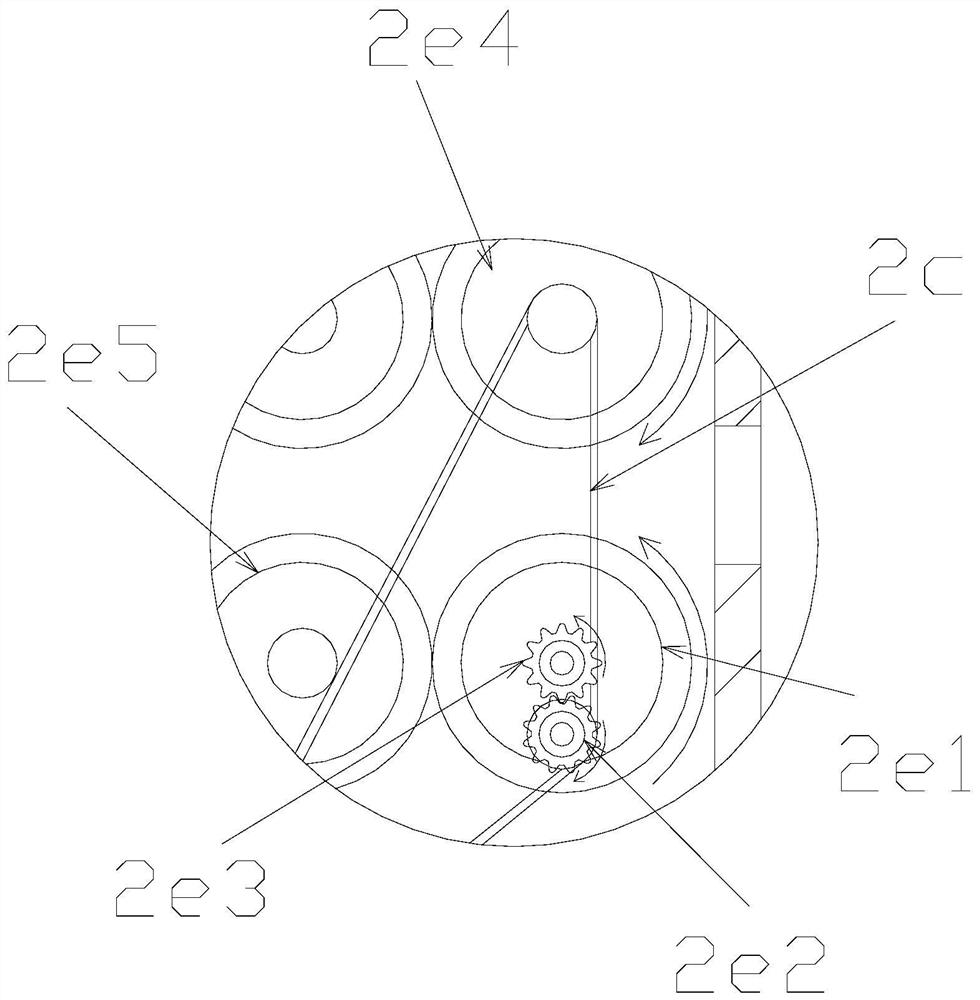

[0031] see Figure 1-Figure 8 , the present invention provides a steel pipe welding machine that is convenient to drag and straighten. Its structure includes a welding frame 1, a dragging device 2, a power distribution control cabinet 3, a welder 4, and a welding rail frame 5. The welding frame Two dragging devices 2 are installed on the top of 1, and a welding guide rail frame 5 is arranged between the two dragging devices 2, and the welding rail frame 5 is movably connected with the welding frame 1, and the welding guide rail A welder 4 is provided on the surface of the frame 5, and the welding rail frame 5 and the welder 4 are slidably matched. The power distribution control cabinet 3 is installed on the surface of the welding frame 1, and the dragging device 2 is controlled by the machine body. 2a, feeding hole 2b, transmission belt 2c, driving motor 2d, feeding mechanism 2e, positioning guide wheel 2f, steel pipe fixing head 2g, and chuck mechanism 2h. The body 2a is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com