The Method of Improving the Anti-cavitation Performance of the Impeller

An impeller and performance technology, applied in the field of anti-cavitation centrifugal impeller, can solve problems such as increase of absolute and relative velocity of liquid flow, uneven distribution of impeller inlet velocity, deterioration of pump cavitation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

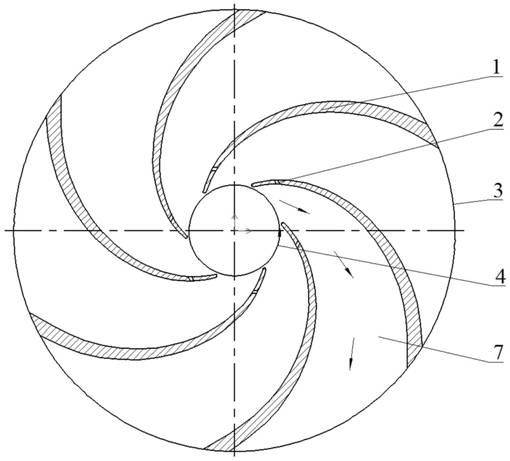

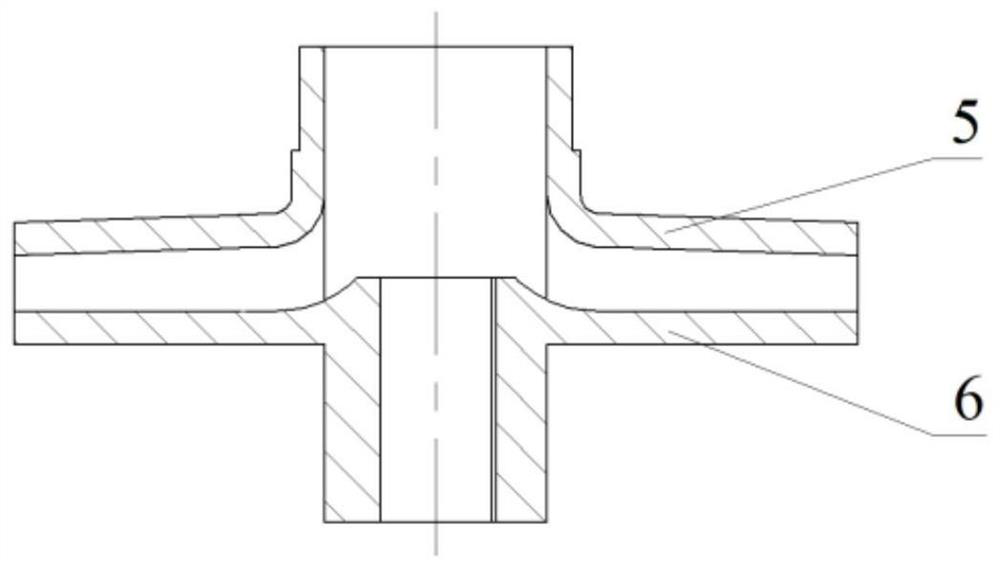

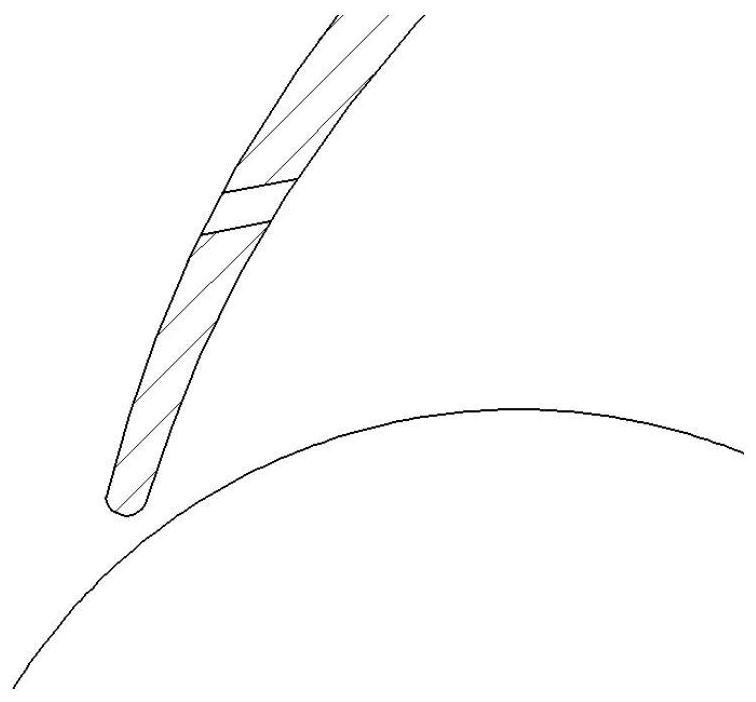

[0017] refer to figure 1 . According to the present invention, an inducer is installed in front of the first-stage impeller of the pump, and the long blade 1 with a slot fixedly connected to the impeller is surrounded by an Archimedes spiral, and the head of the long blade 1 is rounded, and the distance from the head is A gap 2 with a width of 1mm to 2mm gradually increasing from the inside to the outside is set at the position. The direction of the gap 2 is from the high pressure side to the low pressure side, and the angle between the gap 2 and the flow direction is an acute angle; Calculate the throat area of the blade inlet and the cross-sectional area of the impeller inlet with the angle of attack of the blade inlet, and set the ratio X of the throat area of the blade inlet to the cross-sectional area of the impeller inlet to be at least greater than 0.28; then grind the working surface of the blade inlet before assembly, so that The blade inlet is thinned and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com