A Mine Tailings Paste Slurry Loop Test System and System Operation Method

A mine tailings and testing system technology, applied in the pipeline system, measuring device, gas/liquid distribution and storage, etc., can solve the problem that data acquisition and analysis work can only be carried out again, the process of deposition and scaling is slow, waste of time and Energy and other issues, to achieve the effect of reducing repetitive work, small footprint, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

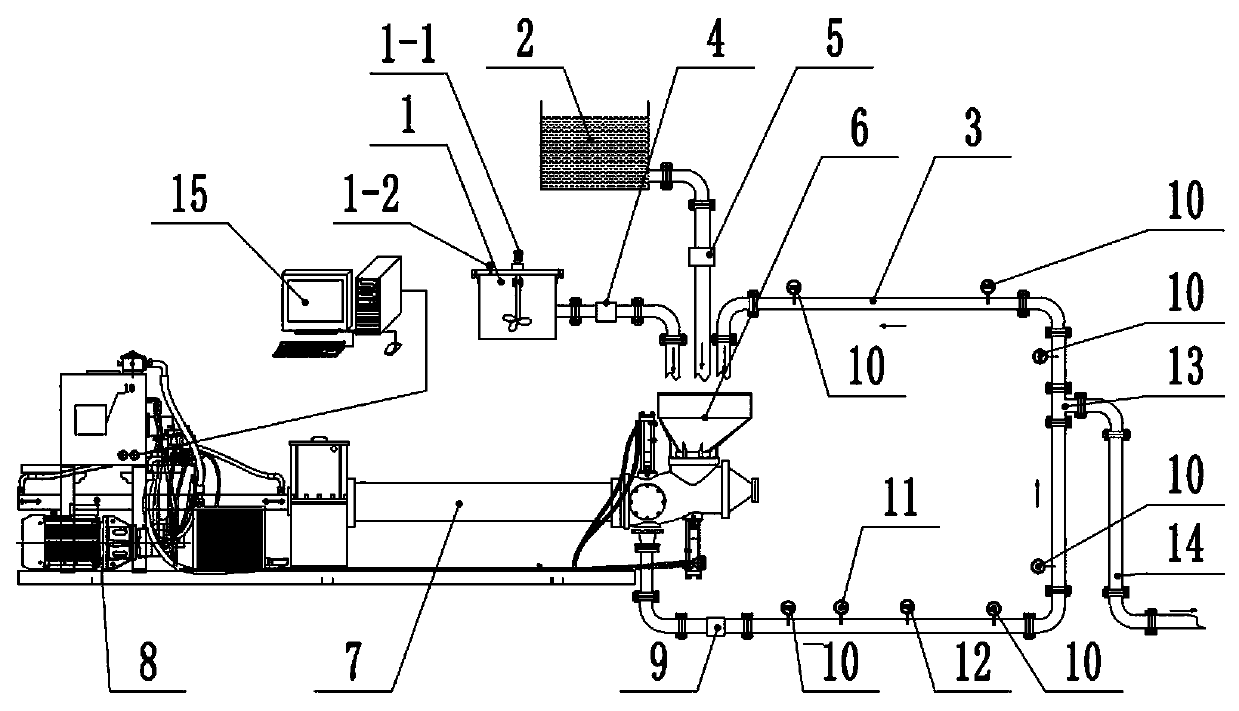

[0045] Such as figure 1 , a mine tailings paste slurry ring pipe testing system, comprising a slurry preparation system 1, a water supply system 2, a hopper 6, a pumping mechanism 7, a pipeline 3 and a signal acquisition system.

[0046] The discharge port of the slurry preparation system 1 and the discharge port of the water supply system 2 are respectively communicated with the hopper 6, and are respectively used to transport the slurry and flushing water to the hopper 6; the pumping mechanism 7 is used to feed the hopper 6 The material in the pipe is pumped into the pipeline 3, and the pipeline 3 includes an elbow section and a straight pipe section, and the outlet of the pipeline 3 communicates with the hopper 6 to form a circulation pipeline.

[0047] The slurry preparation system 1 includes a mixing tank and a stirring device 1-1 installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com