Tail flue built-in loop-shaped circulating fluidized bed boiler and driving power generation system thereof

A circulating fluidized bed and tail flue technology, applied in fluidized bed combustion equipment, machines/engines, indirect carbon dioxide emission reduction, etc. and other problems to achieve the effect of realizing energy, improving uniformity, avoiding heat absorption and serious temperature unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

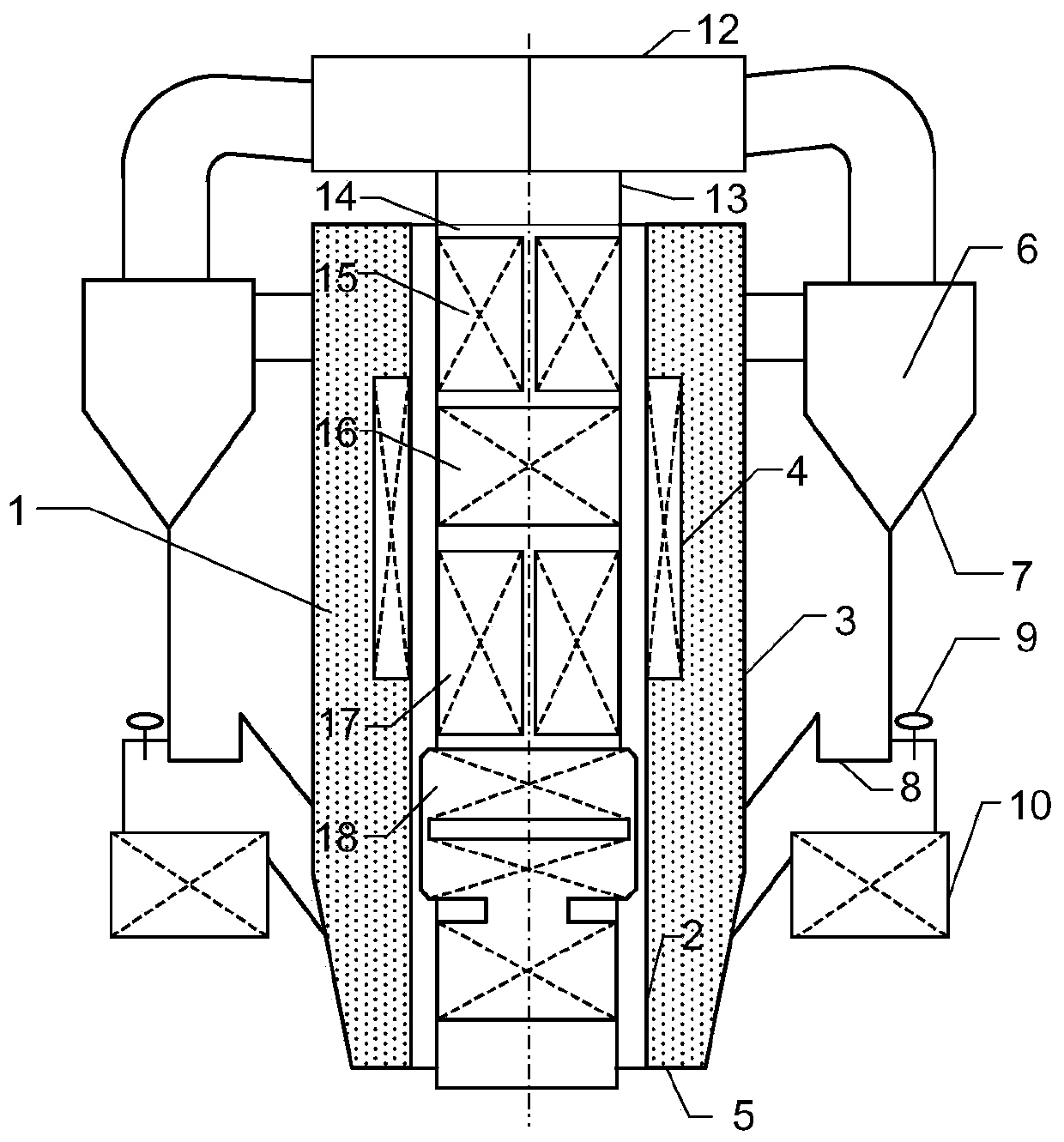

[0043] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

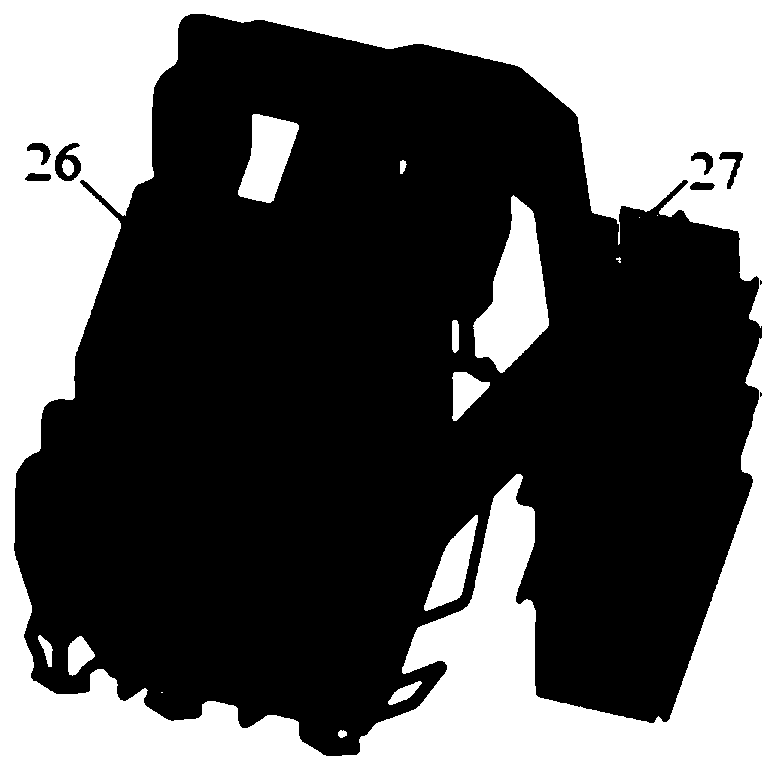

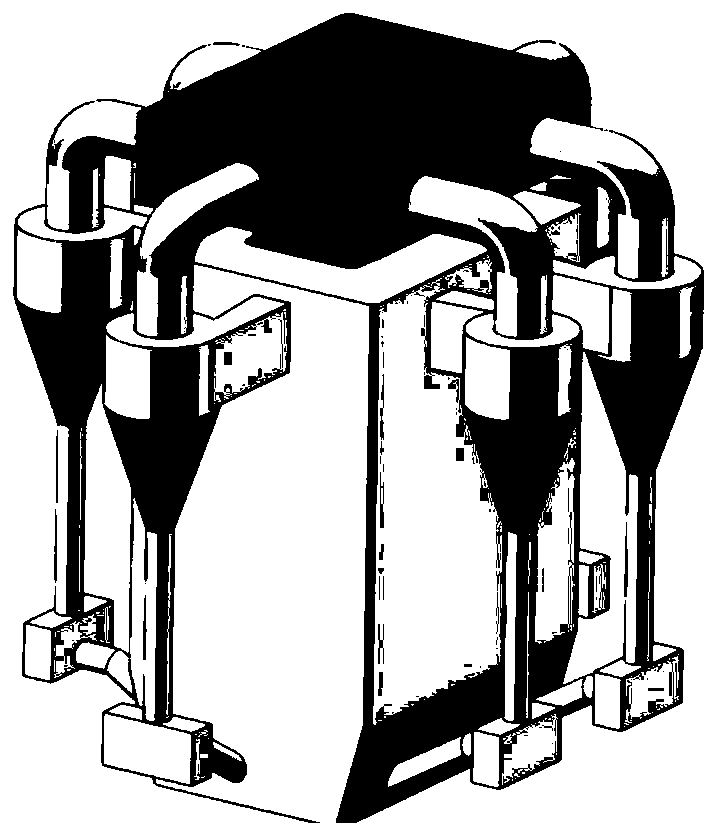

[0044] As shown in Figure 1(a), the inventors have found through research that the tail flue 27 of the circulating fluidized bed boiler in the prior art is arranged on the side of the boiler body 26, which is one of the reasons for the asymmetry of the structure of the separator outlet flue. one. At present, almost all circulating fluidized beds use the tail flue located on one side of the furnace body, and the flue gas from the outlets of multiple separators is sequentially collected into one or two upper flues, and then leads to the tail flue. The fluidized bed boiler system of this design occupies a large area as a whole. At the same time, this sequentially converging flue structure fundamentally determines the difference in the dynamic state at the outlet of each separator, resulting in uneven working conditions of the separators. . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com