Recovery device for sensible heat of powdery solid

A sensible heat recovery, powder-like technology, applied in the direction of waste heat treatment, indirect heat exchangers, heat exchanger types, etc., can solve the problem of inconvenient popularization and use of powder-like solid waste heat utilization devices, failure to meet industrial and environmental protection needs, boiler systems can not Normal work and other problems, to achieve the effect of uniform and stable heat transfer, reasonable structure, and increase the amount of waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

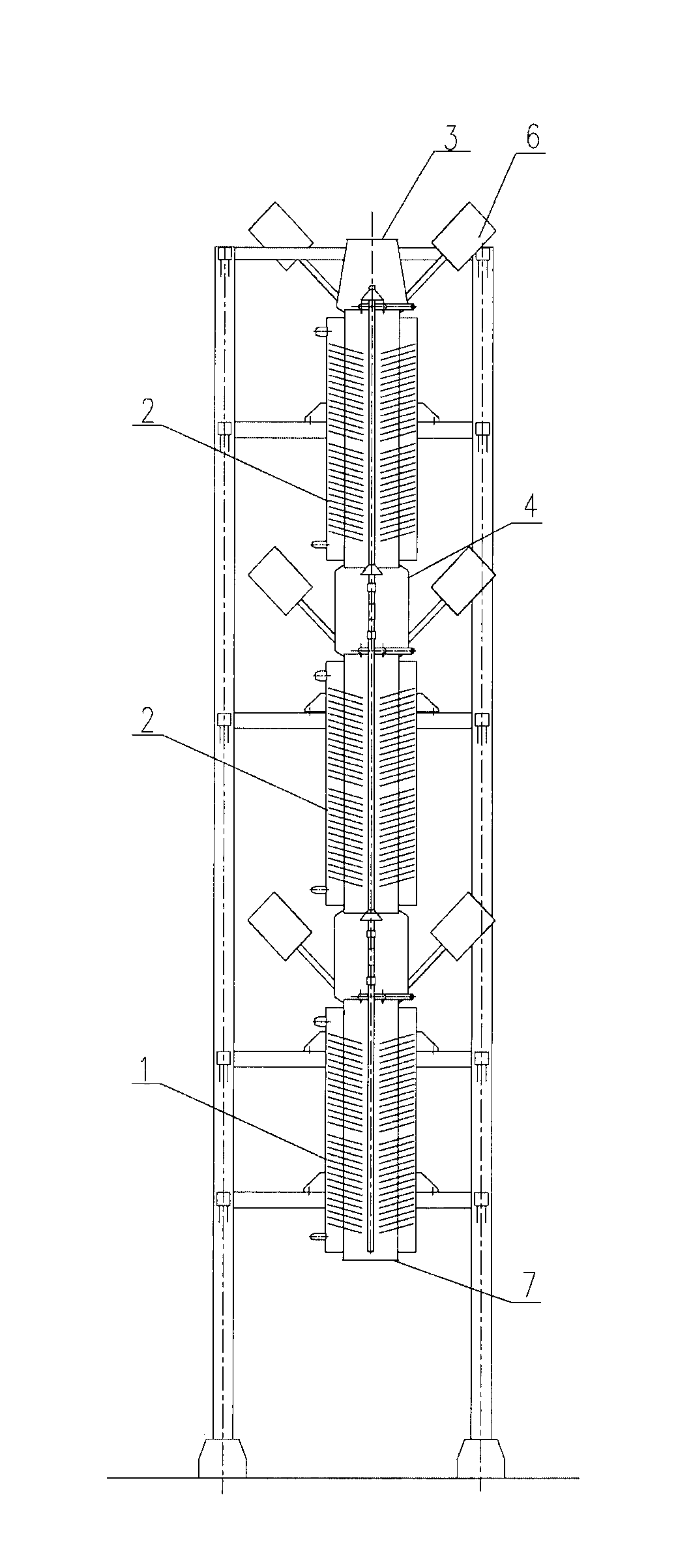

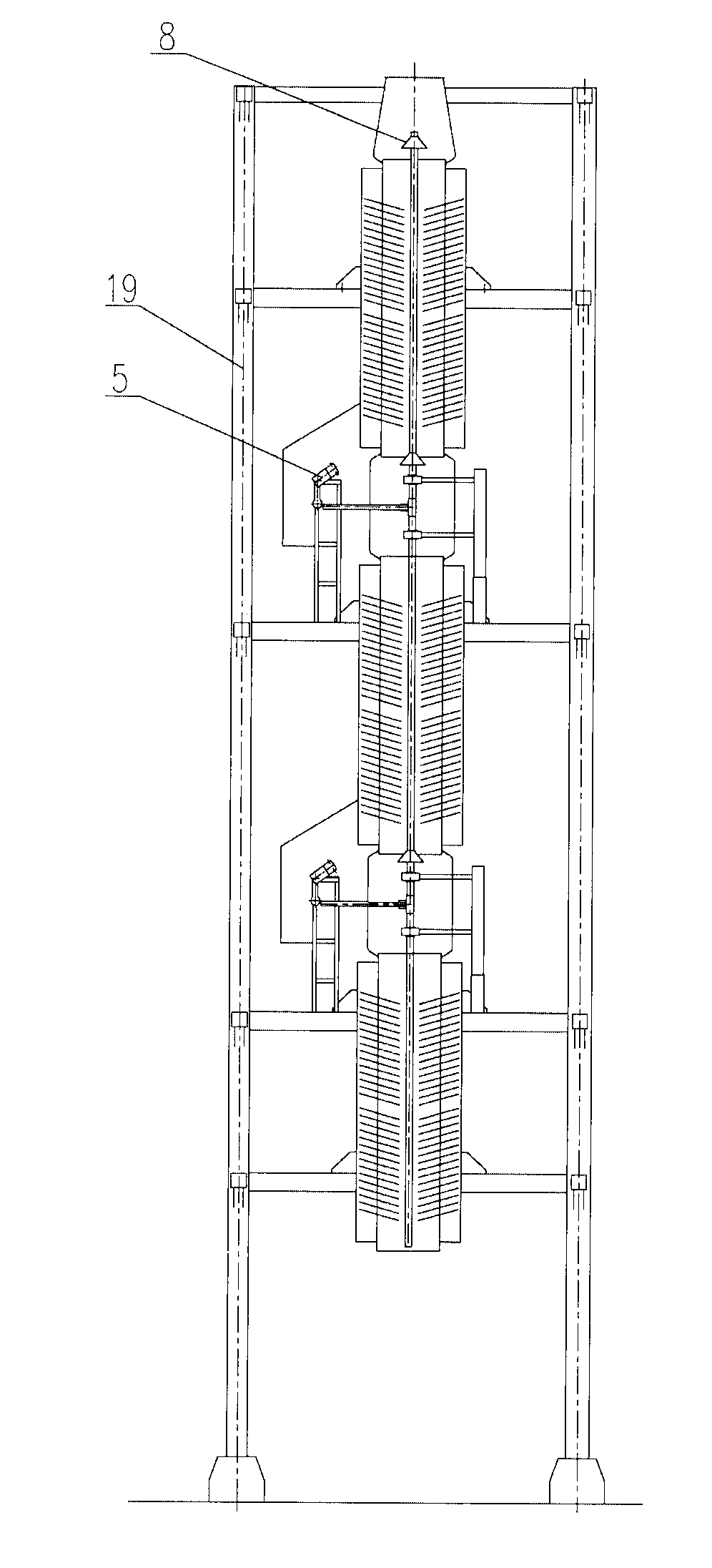

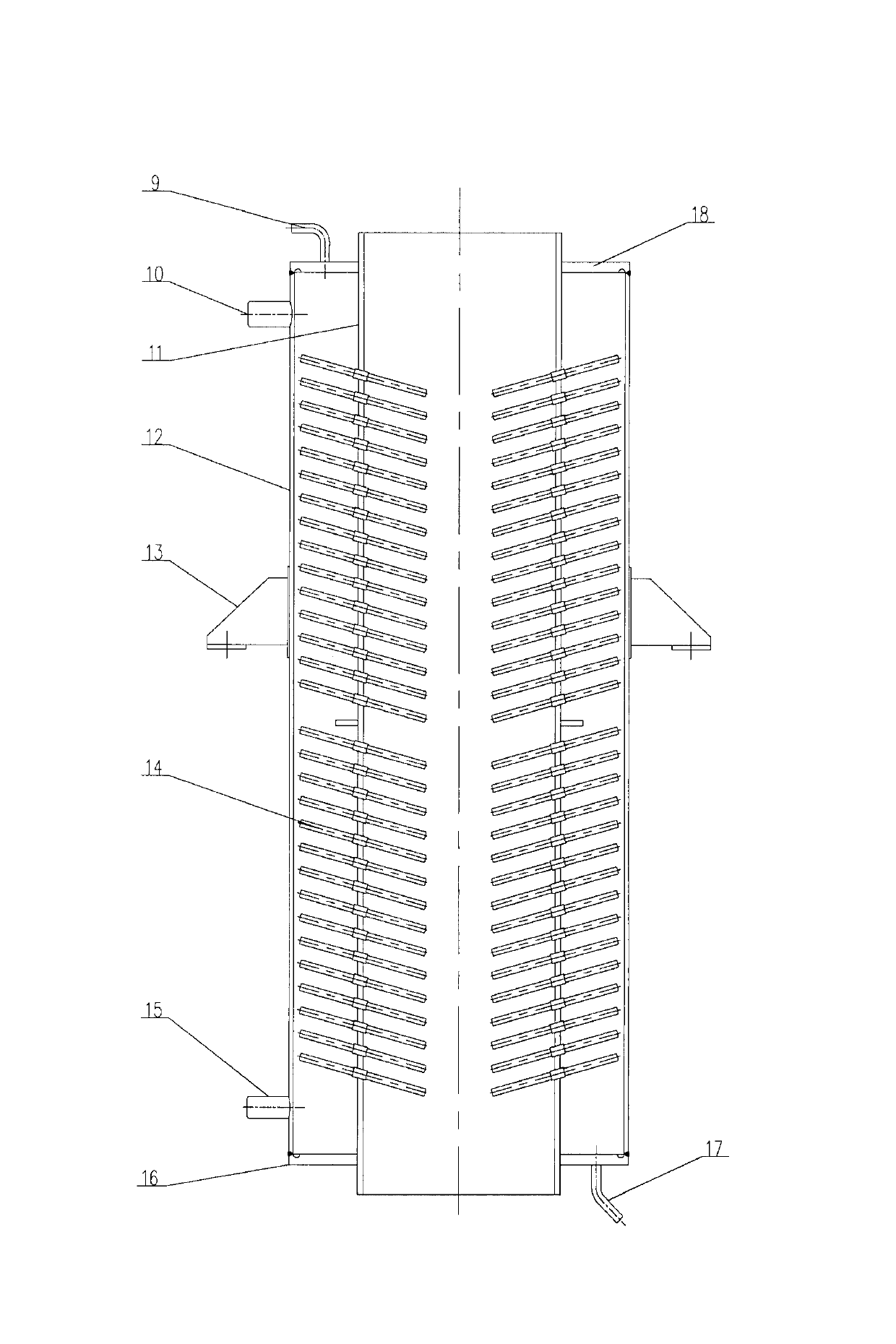

[0022] detailed description The invention mainly includes a coal economizer, an evaporator, a pipeline, a material inlet and a material outlet. The upper part of the economizer is vertically connected to the evaporator through the pipeline in turn. The top port of the top evaporator is the material inlet, and the bottom port of the bottom economizer is the material Outlet; there is a support frame around the economizer and evaporator, and each layer of economizer and evaporator is welded on the support frame; the economizer and evaporator have the same structure, and are composed of an inner cylinder and an outer cylinder. There is a coaxial inner cylinder in the outer cylinder, and the inner and outer cylinders are welded and closed by the upper head and the lower head to form an annular cylinder; one end of the heat pipe is inserted into the interlayer of the inner and outer cylinders, and the other end is in the inner cylinder; in the economizer The lower end of the out...

Embodiment 1

[0026] Two evaporators and one economizer are selected. The economizer is located at the bottom, and then the evaporators are connected layer by layer upward to form a vertical connection structure. There are supporting frames outside the evaporator and the economizer. The frame is composed of four vertical support legs and multiple beams to form a cubic frame structure. The support frame surrounds the evaporator and economizer, and is welded together with the ear brackets of the evaporator and economizer through horizontal metal rods. The bracket consists of two brackets, which are symmetrically installed on the outer walls of the evaporator and the economizer. The evaporator and the economizer are composed of inner and outer cylinders, and the inner and outer cylinders all adopt a cylindrical structure, and the upper and lower seals form a ring structure, and the upper and lower adjacent evaporators (or evaporators and economizers) are connected by pipelines. The pipe adopts...

Embodiment 2

[0028] Three evaporators and one economizer are selected, the economizer is at the bottom, and then the evaporators are connected and installed layer by layer upwards, forming a vertical connection structure as a whole, and there are supporting frames outside the evaporator and the economizer. The support frame consists of four vertical support legs and a plurality of beams to form a cubic frame structure. The support frame surrounds the evaporator and the economizer, and is welded together with the ear brackets of the evaporator and the economizer through horizontal metal rods , The ear bracket consists of three brackets that are triangularly symmetrically distributed on the outside of the evaporator and economizer. A coaxial rapping rod is installed in the inner cylinder. In order to ensure that the solid powder can evenly fall from the inner cylinder into the ash hopper, a distributor is installed on the rapping rod, and a rapping hammer is arranged at the pipeline between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com