H-shaped finned tube type phase-change heat reservoir

A finned tube type, phase change heat storage material technology, applied in the field of H-type finned tube type phase change heat storage, can solve the problems of uneven heat transfer, poor effect and low thermal conductivity of phase change heat storage , to achieve the effect of uniform melting or solidification process, increased heat transfer area, and strong heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

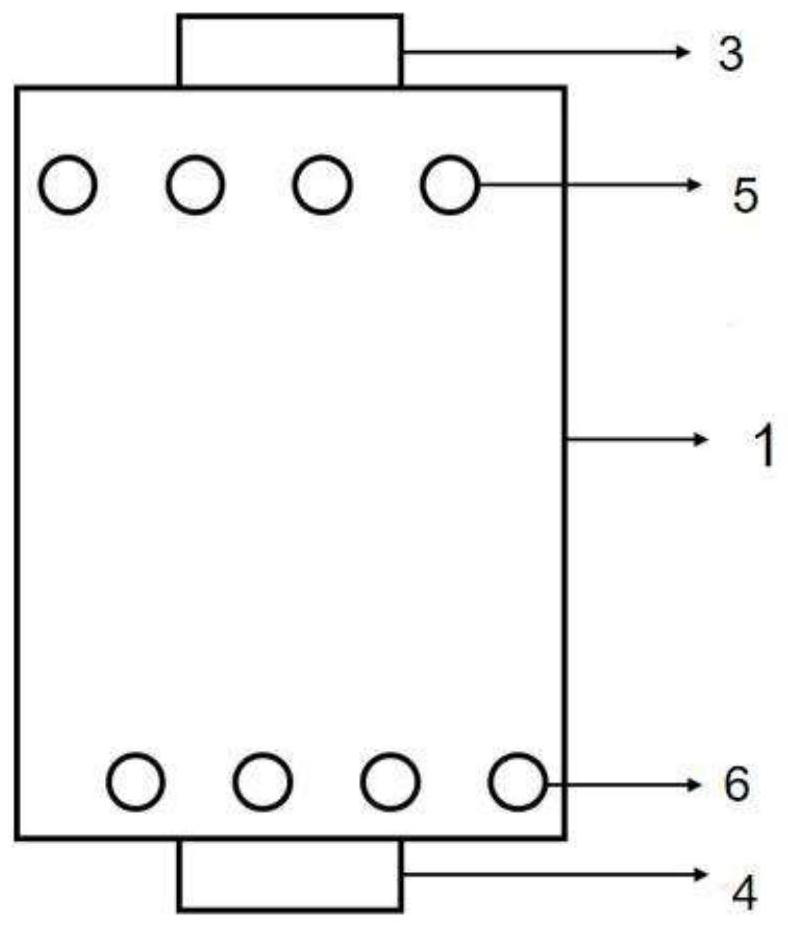

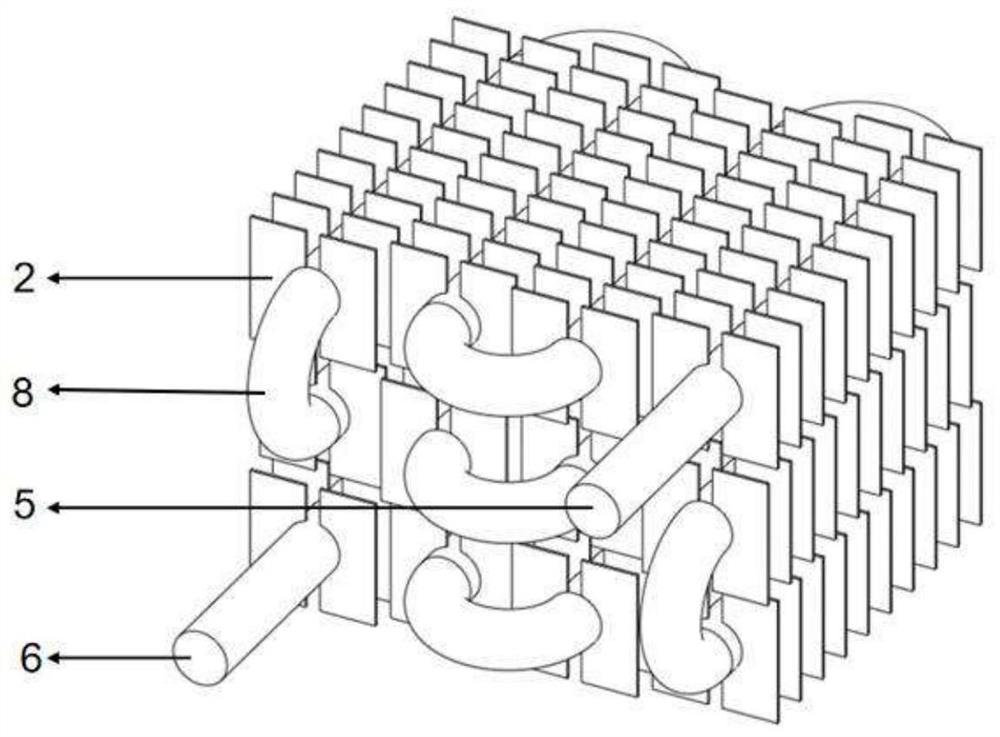

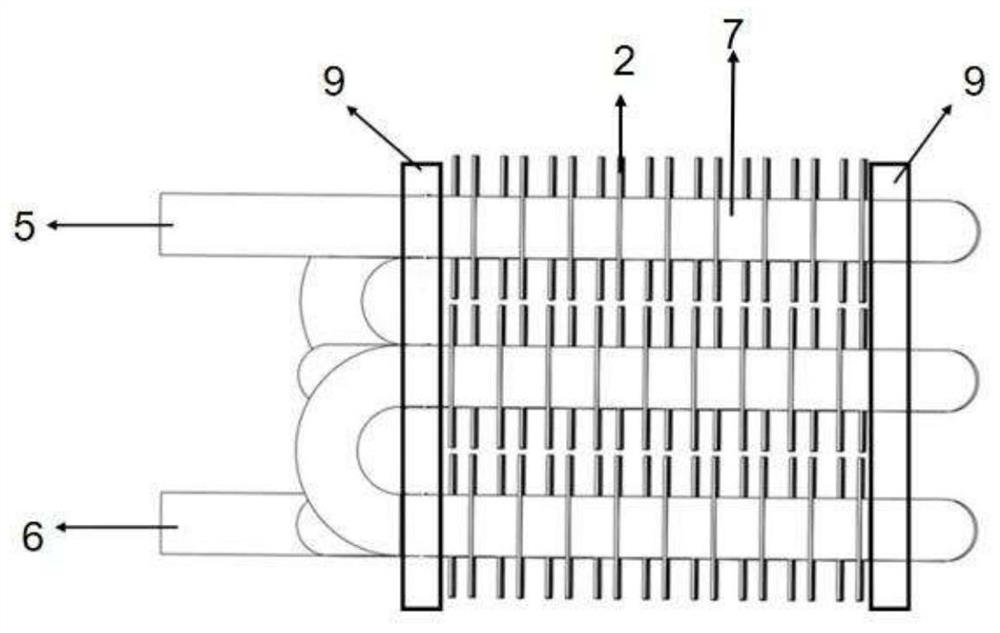

[0030] Taking the phase change heat storage applied to power grid peak regulation or renewable surplus electricity as an example, the mixed inorganic salt of nitrate and carbonate is used as the phase change heat storage material, the phase change temperature is 230°C, and the heat transfer oil is used as the heat transfer material. Thermal medium; in the phase change heat storage, 4 sets of H-type finned heat exchange tubes are connected in parallel as the heat transfer channel. The size of the H-type finned tubes is 88×88mm, the middle gap is 10mm, the thickness is 2mm, and the longitudinal intercept is 30mm. Staggered arrangement; the angle steel fixes the H-shaped finned heat exchange tube group from the front and rear positions; the working temperature of the phase change heat storage is 220°C-240°C, the working temperature of the heat transfer oil is 180-300°C, and its working principle is :

[0031] Heat storage: high-temperature heat transfer oil flows in from the uppe...

Embodiment 2

[0034] Taking the phase change heat storage device used in trough solar thermal power generation as an example, water is used as the heat transfer medium, and H-shaped finned heat exchange tubes are installed inside, of which the size of the H-shaped finned tubes is 88×88mm, and the middle gap is 10mm , thickness 2mm, longitudinal intercept 30mm, staggered arrangement; during heat storage, water vapor flows in from the upper interface 5 of the H-shaped finned heat exchange tube group to heat the phase change material. After the working medium changes from water vapor to water, it changes from H The lower interface 6 of the H-shaped finned heat exchange tube group flows out; when releasing heat, water flows in from the lower interface 6 of the H-shaped finned heat exchange tube group to absorb the heat of the phase change material. After the working medium changes from water to steam, It flows out from the upper port 5 of the H-shaped finned heat exchange tube group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Heat transfer area | aaaaa | aaaaa |

| Heat transfer area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com