Preparation method of coated guanidinoacetic acid

A guanidinoacetic acid and coating technology, which is applied in the field of preparation of coated guanidinoacetic acid, can solve the problems of low bioavailability, inability to achieve sustained release, and high degradation rate, so as to reduce degradation rate, improve rumen passing rate, and stabilize good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

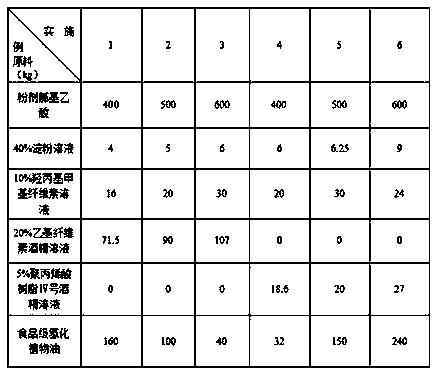

[0036] Embodiment 1-6 A kind of coated guanidinoacetic acid

[0037] Examples 1-6 are respectively a kind of coated guanidinoacetic acid, and its raw material formula is shown in Table 1.

[0038] The raw material formula of table 1 embodiment 1-6

[0039]

Embodiment 7

[0040] Example 7 A preparation method of coated guanidinoacetic acid

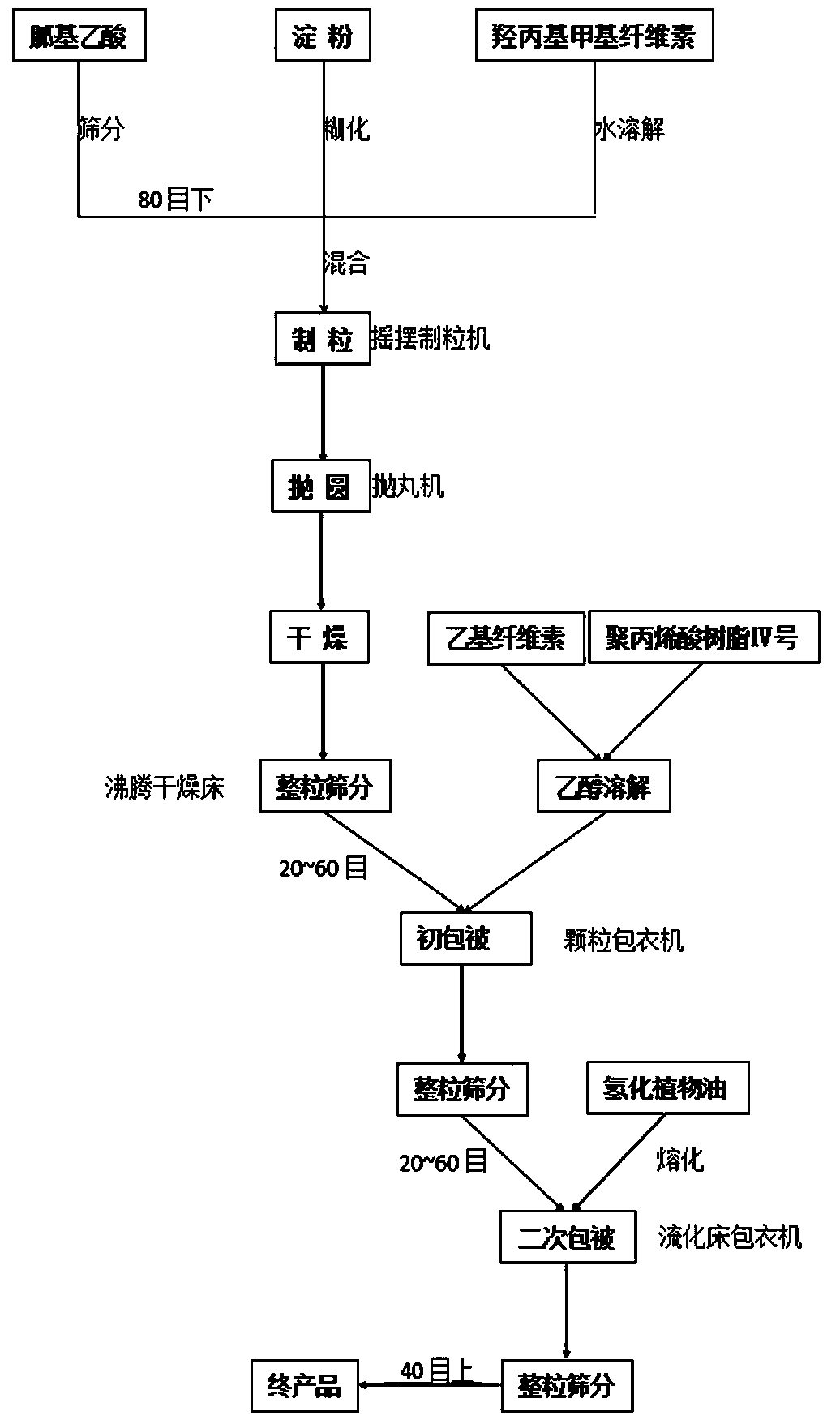

[0041] This embodiment is used to prepare the guanidinoacetic acid described in any one of embodiments 1-6, comprising the following steps carried out in sequence:

[0042] (1) Pretreatment

[0043] The powder guanidinoacetic acid is first ultrafinely pulverized, then shaken through an 80-mesh sieve, graded and sieved, and the 80-mesh guanidinoacetic acid is taken as a raw material;

[0044] (2) Ball core preparation

[0045] After pulverizing and sieving, 400 parts of powder guanidinoacetic acid and 4 parts of gelatinized starch solutions with a concentration of 40% and 16 parts of hydroxypropyl methylcellulose solutions with a concentration of 10% were placed in a mixer and mixed evenly. After being extruded into granules by a swinging granulator, they are added to a rounding machine to form spherical granules. The spherical granules are swayed through a 40-mesh screen, sorted, graded and sieved, and th...

Embodiment 8-11

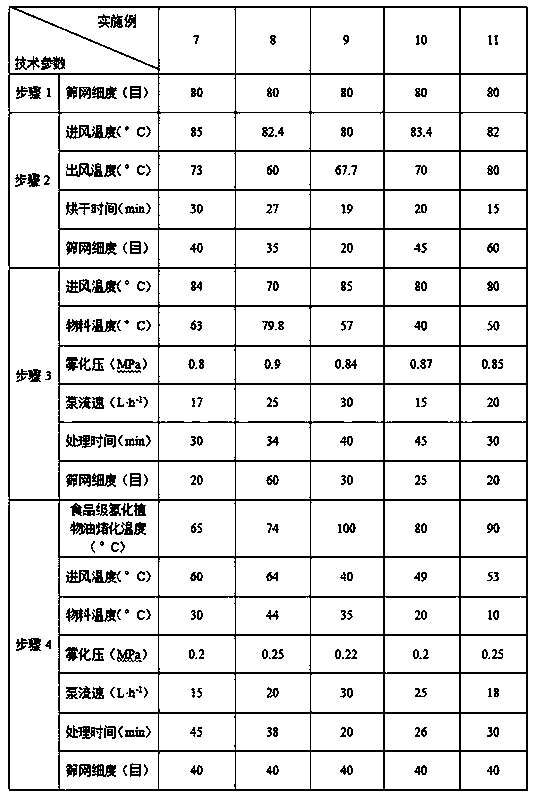

[0054] Example 8-11 A preparation method of coated guanidinoacetic acid

[0055] Embodiments 8-11 are respectively a preparation method for coating guanidinoacetic acid, which is used to prepare the guanidinoacetic acid described in any one of Examples 1-6, and the preparation steps are the same as those in Example 7, with the difference The difference is that the technical parameters in the preparation process of the coated guanidinoacetic acid are different, see Table 2 below for details.

[0056] Table 2 Technical parameters in the preparation process of Examples 8-11

[0057]

[0058] In this example, the active ingredient of the second-coated guanidinoacetic acid finally obtained in Example 7 can be as high as 67.8%. The active ingredient of the second coating of the finally obtained guanidinoacetic acid in Example 8 can be as high as 78.7%. The active ingredient of the guanidinoacetic acid finally obtained in Example 9 after secondary coating can be as high as 86.8%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com