Machining technology and manufacturing technology of hub

A manufacturing process and machining technology, applied in the field of machining process and manufacturing process of wheel hub, can solve the problems of low production efficiency, runout and dynamic balance out of tolerance, improper clamping and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

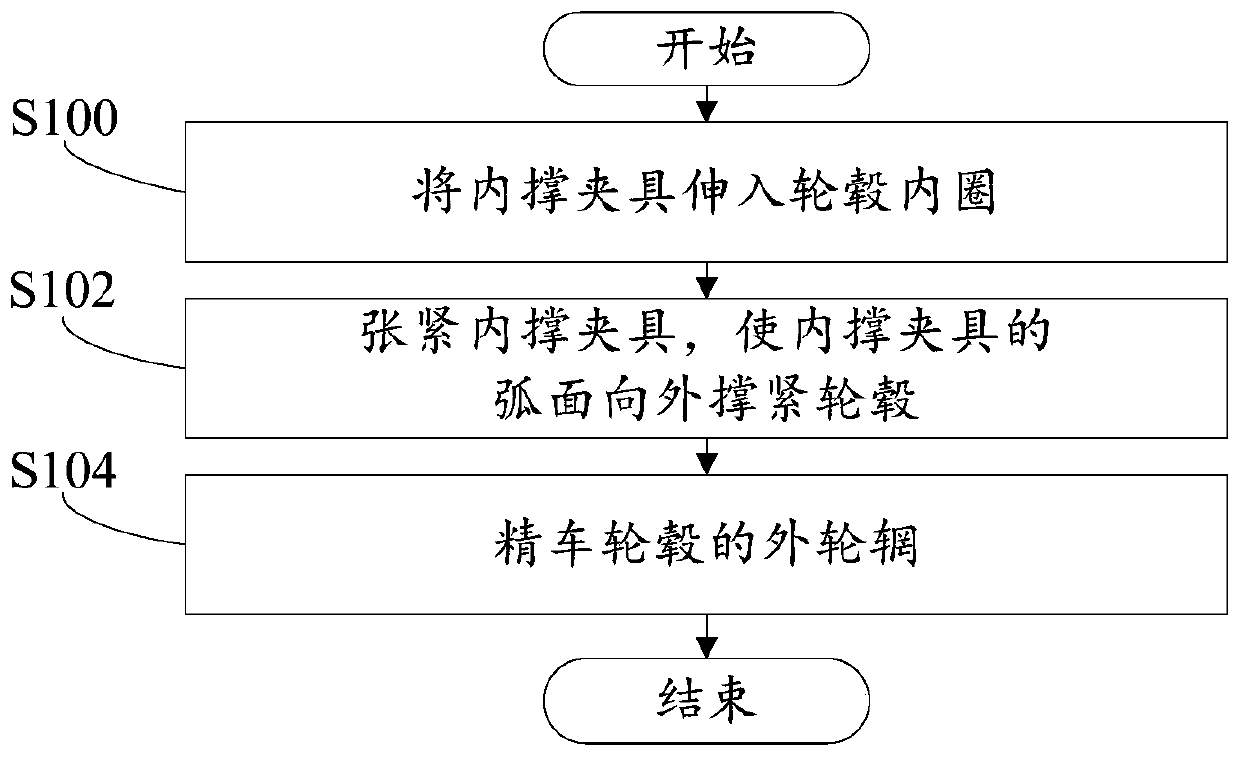

[0034] Such as figure 1 As shown, the machining process of the hub according to an embodiment of the present invention includes:

[0035] Step S100: extending the inner support fixture into the inner ring of the hub;

[0036] Step S102: Tensioning the inner support fixture, so that the arc surface of the inner support fixture tightens the wheel hub outward;

[0037] Step S104: Finishing the outer rim of the wheel hub.

[0038] In this embodiment, the clamping of the hub is achieved from the inside of the hub by using the inner support fixture to extend into the inner ring of the hub. Since the inside of the hub is not easy to be seen, the requirements for appearance are reduced, and the The surface of the supporting fixture is an arc surface, which is easy to fit with the inner surface of the hub and increases the contact area between the inner supporting fixture and the inner surface of the hub, thereby reducing the pressure of the fixture on the inner surface of the hub, t...

Embodiment 2

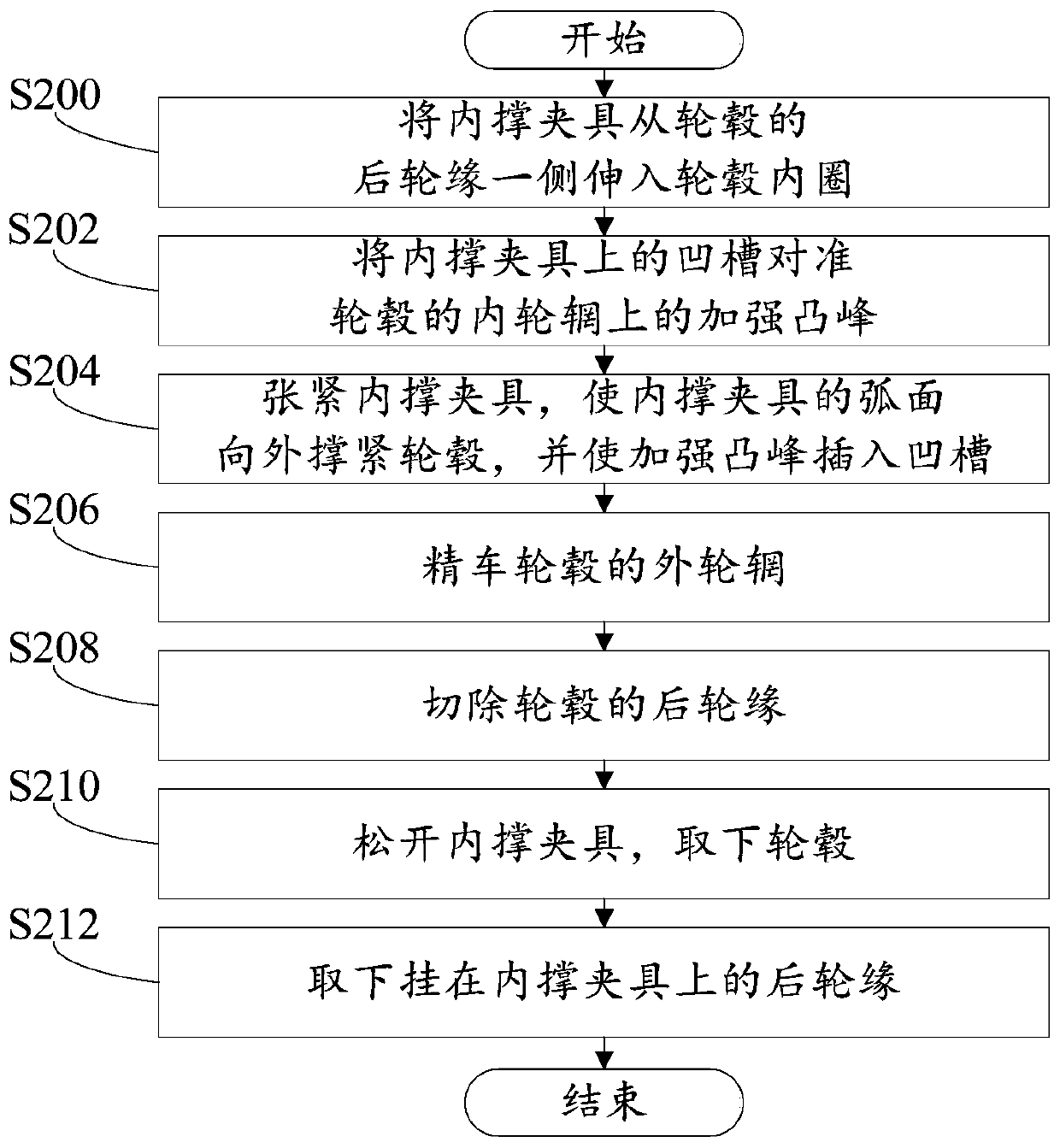

[0041] Such as figure 2 As shown, on the basis of Embodiment 1, the machining process of the hub according to another embodiment of the present invention includes:

[0042] Step S200: extending the inner support fixture from the rear rim side of the wheel hub into the inner ring of the wheel hub;

[0043] Step S202: Align the groove on the inner support fixture with the reinforcing peak on the inner rim of the hub;

[0044] Step S204: tensioning the inner support fixture, so that the arc surface of the inner support fixture tightens the wheel hub outward, and inserts the reinforcing peak into the groove;

[0045] Step S206: finishing the outer rim of the wheel hub;

[0046] Step S208: cutting off the rear rim of the wheel hub;

[0047] Step S210: loosen the inner support fixture, and take off the wheel hub;

[0048] Step S212: Take off the rear wheel rim hanging on the inner support fixture.

[0049]In this embodiment, by extending the inner support fixture from one side...

Embodiment 3

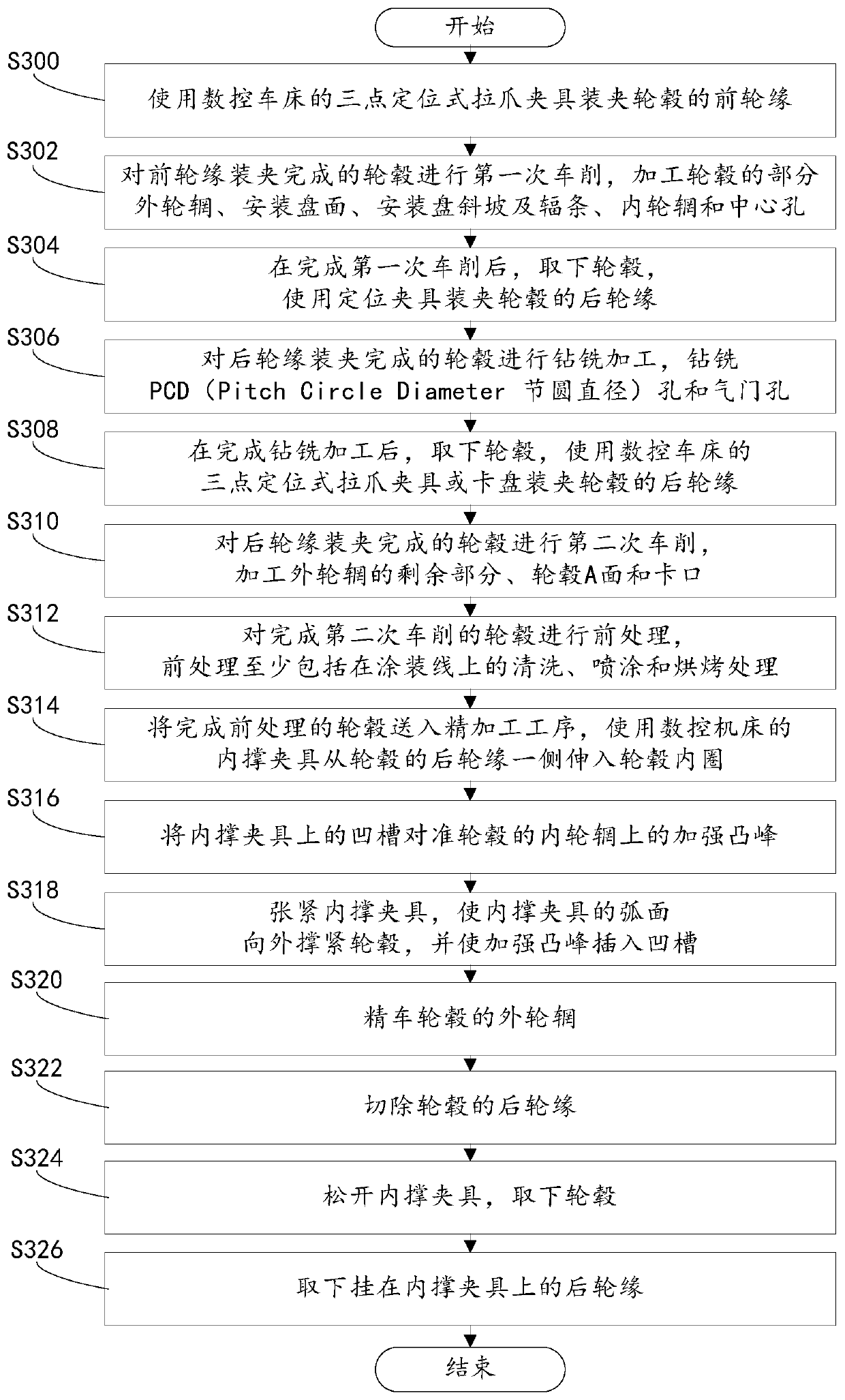

[0051] Such as image 3 As shown, on the basis of Embodiment 1 and Embodiment 2, the machining process of the hub according to another embodiment of the present invention includes:

[0052] Step S300: clamping the front rim of the wheel hub with a three-point positioning claw fixture of a CNC lathe;

[0053] Step S302: Carry out the first turning of the wheel hub after the clamping of the front rim, and process part of the outer rim of the wheel hub, the surface of the mounting plate, the slope of the mounting plate and the spokes, the inner rim and the center hole;

[0054] Step S304: after the first turning, the wheel hub is removed, and the rear rim of the wheel hub is clamped with a positioning fixture;

[0055] Step S306: Drilling and milling the wheel hub after the clamping of the rear rim, drilling and milling PCD (Pitch Circle Diameter) holes and valve holes;

[0056] Step S308: After the drilling and milling process is completed, the wheel hub is removed, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com