an electric spindle

A technology of electric spindles and mandrels, which is applied to metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc. It can solve the problems of high working temperature of the back-end bearings, inability to dissipate heat from the back-end bearings, and heating of the bearings to avoid Severe heat generation, ensure the working temperature, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

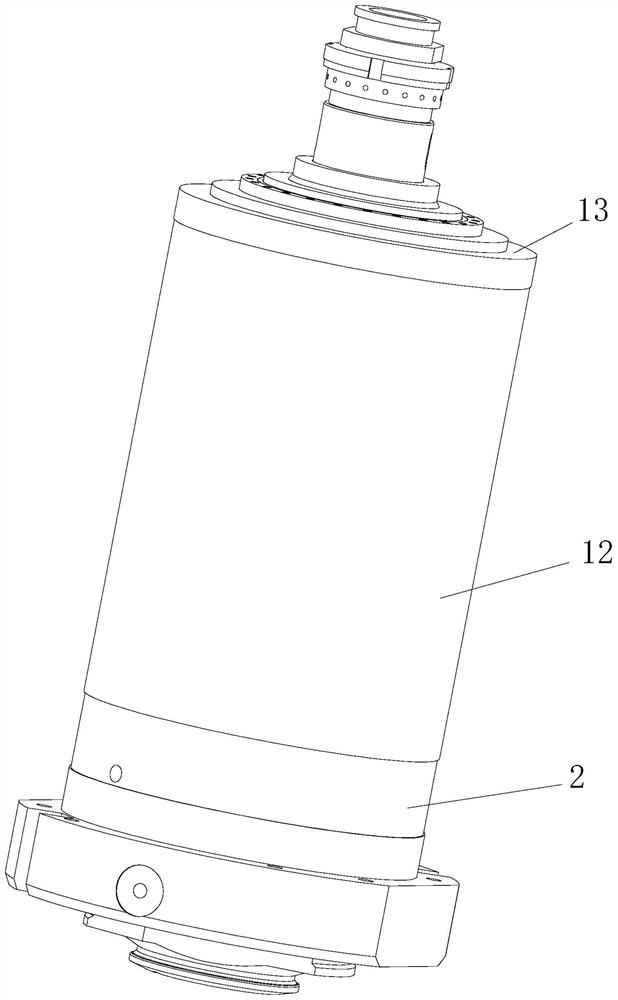

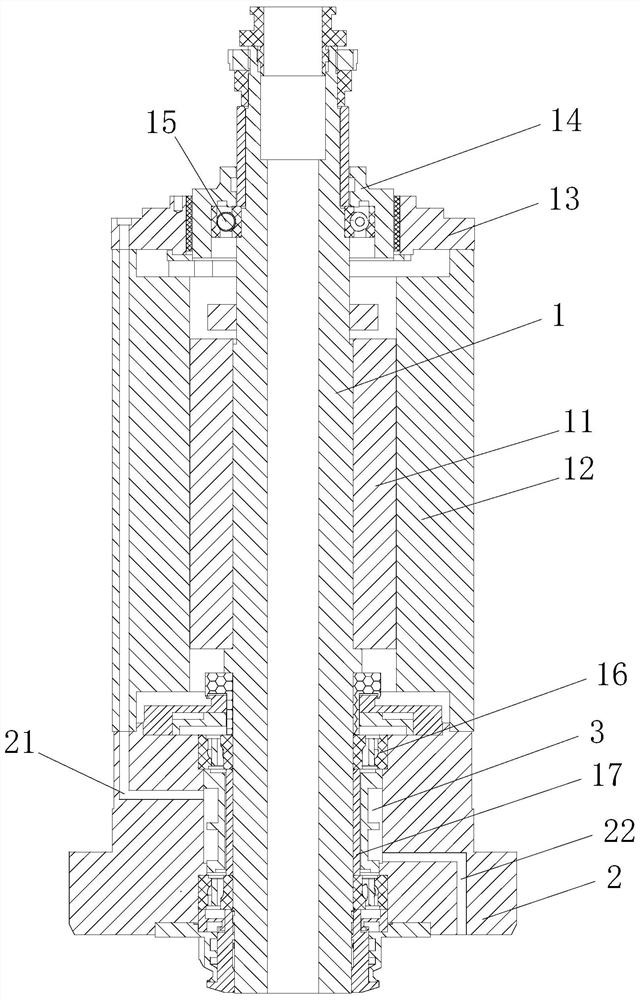

[0038] Such as figure 1 As shown, an electric spindle includes a mandrel 1, a rotor 11 fixed on the mandrel 1, a fixed stator 12, two rear end bearings 16 arranged at the rear of the mandrel 1, sleeved on the rear end The rear end bearing seat 2 on the bearing 16 , the deep groove ball bearing 15 arranged on the front part of the mandrel 1 and the front end bearing seat 14 sleeved on the deep groove ball bearing 15 .

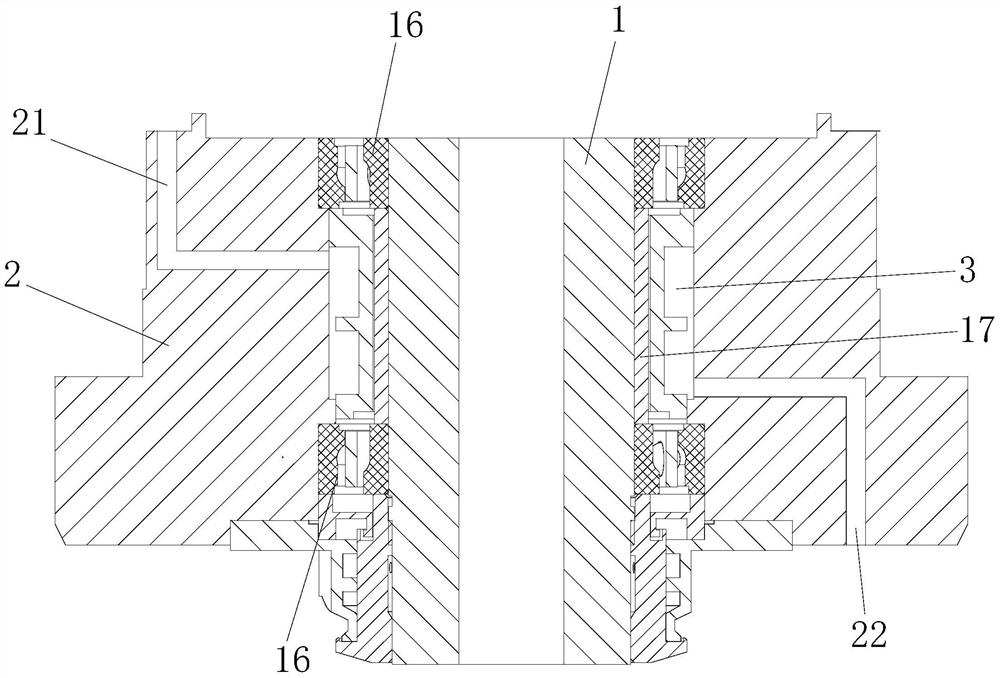

[0039] Such as Figure 2-4 As shown, the first shaft sleeve 17 is sleeved on the mandrel 1 between the two rear end bearings 16, and a cooling chamber 3 is sleeved on the first shaft sleeve 17. The baffles 32 at both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com