Testing equipment and method for wireless charging receiver

A technology of wireless charging and testing equipment, applied in the field of testing, can solve problems such as increased maintenance costs, low energy conversion efficiency, high current shock heating, etc., to ensure stability and reliability, improve test stability, and ensure efficiency and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

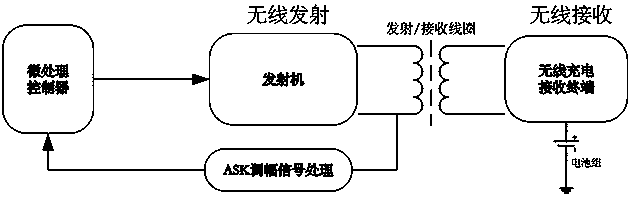

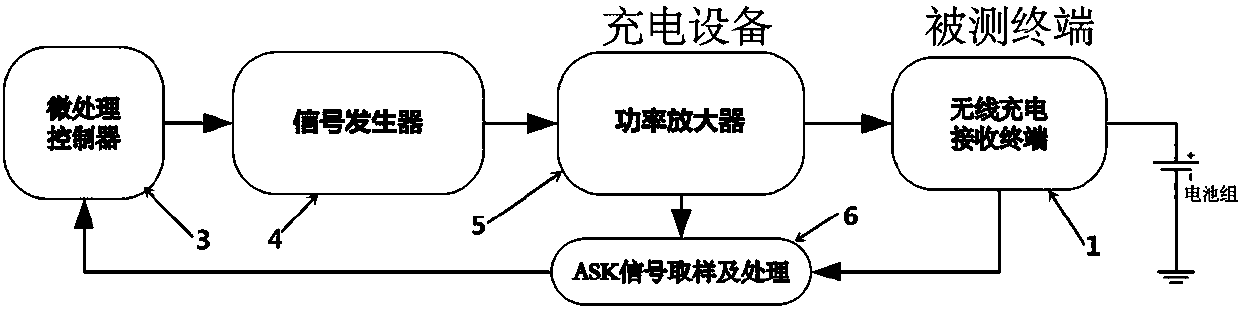

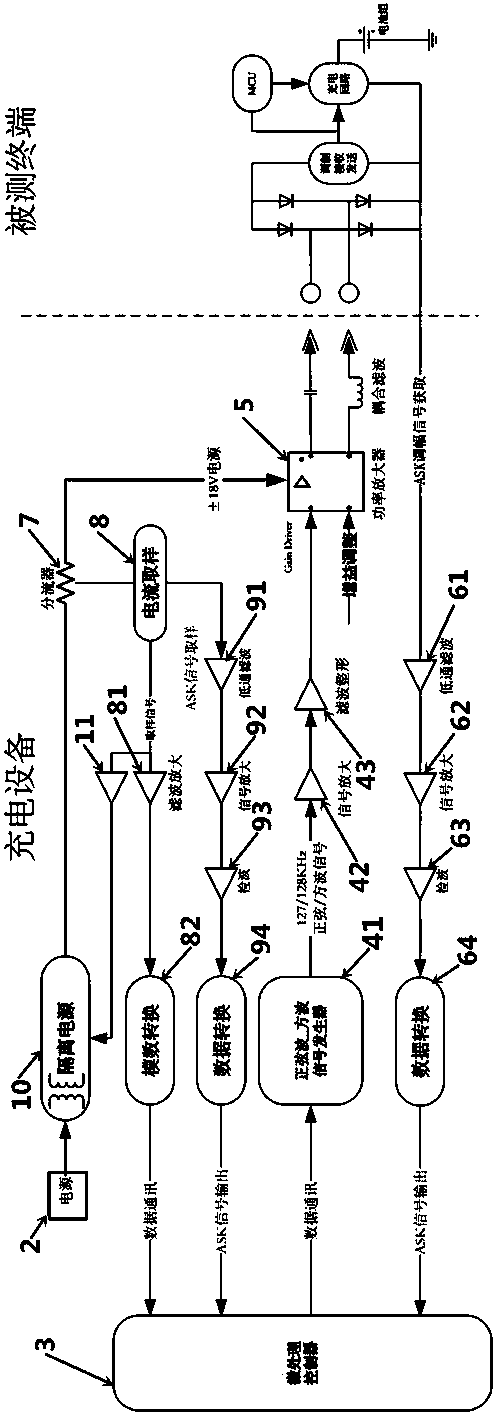

[0044] Such as figure 2 As shown, the present invention includes wireless charging receiver 1 and power supply 2, and it also includes microprocessor controller 3, signal generator 4, power amplifier 5 and ASK signal sampling and processing module 6, in the present invention, as Figure 13 As shown, the model of the microprocessor controller 3 is XC7Z010. The microprocessor controller 3, the signal generator 4 and the power amplifier 5 are sequentially connected, the power amplifier 5 is directly coupled and connected to the wireless charging receiving end 1, and the ASK signal sampling and processing module 6 is connected to Between the microprocessor controller 3 and the wireless charging receiving end 1 , the power supply 2 supplies power to the power amplifier 5 . Compared with the prior art, the present invention changes the transmission / reception coil link which is easily lost in the middle into a direct coupling mode, and inputs a PWM signal with a certain power to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com