Energy-saving type hydraulic pressure-shear testing machine

A testing machine, energy-saving technology, applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, measuring devices, etc., can solve the problems of large power loss and heat generation in the system, Achieve the effect of reducing oil energy loss and avoiding serious heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

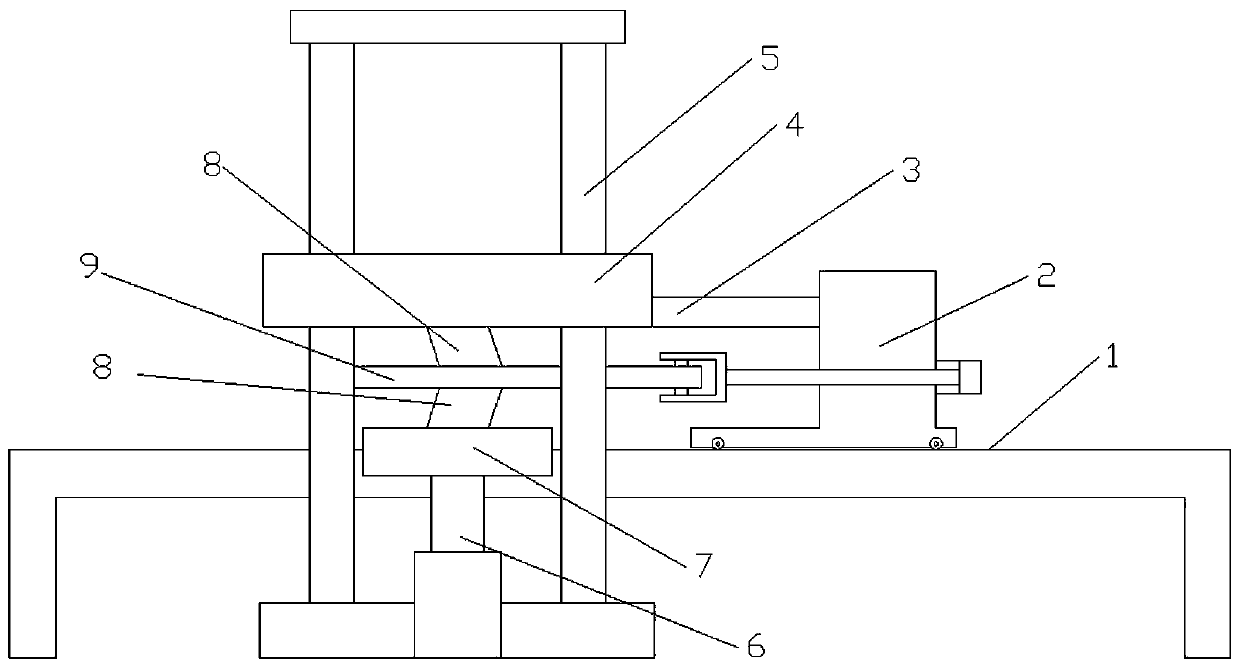

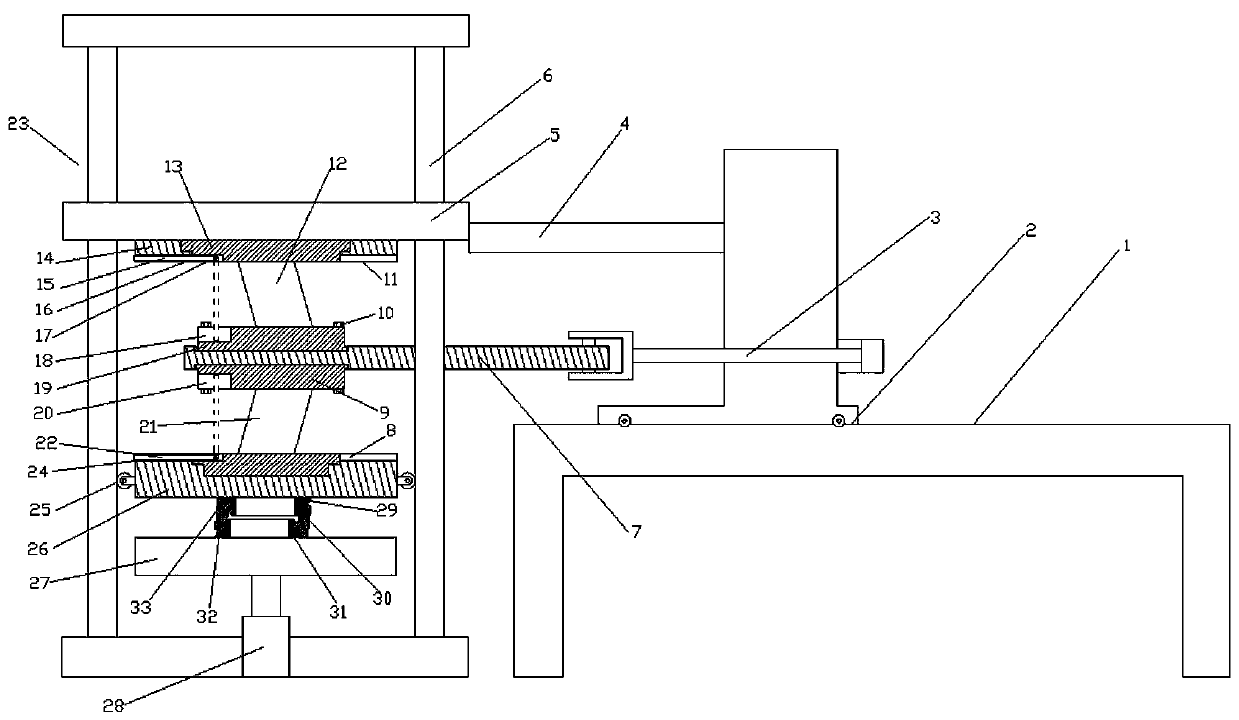

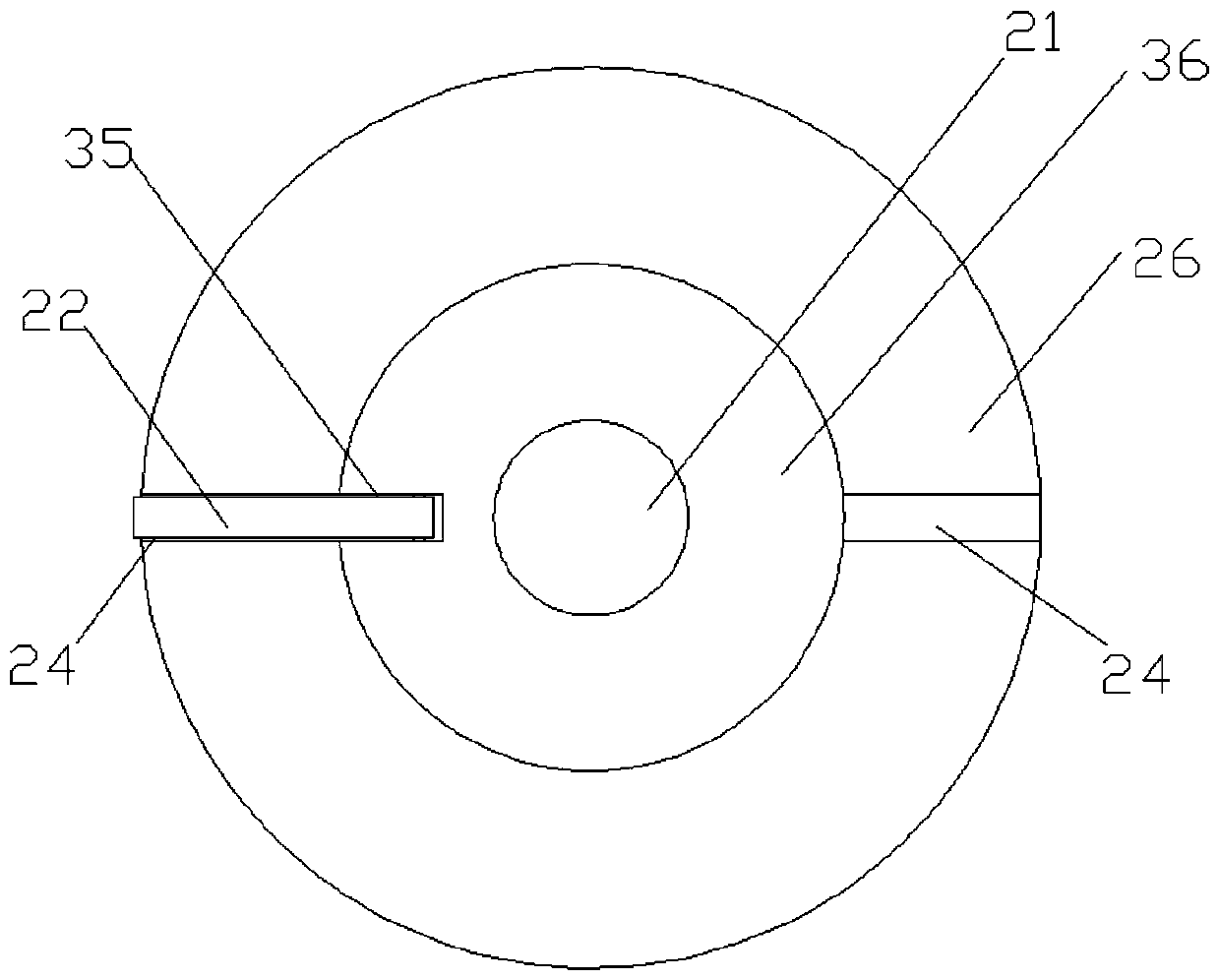

[0018] An example of an energy-saving hydraulic compression shear testing machine Figure 2~6 Shown: includes a vertical loading mechanism and a horizontal loading mechanism, the vertical loading mechanism vertically loads the bracket 23, the vertical loading bracket 23 includes a left limit bracket 61, a right limit bracket 62, and a left limit bracket 61 1. The upper end of the right limit bracket 62 is provided with a crossbeam 5, and the lower end of the crossbeam is provided with an upper pressing plate 14, and the lower side of the upper pressing plate 14 is provided with a lower pressing plate 26, and the left and right sides of the lower pressing plate 26 are connected with the left side limiting bracket, the right Pressing plate limiting rollers 25 are respectively arranged between the side limiting brackets, and the rotation axis of the pressing plate limiting rollers 25 extends along the front and rear directions. The limit roller cooperates with the rolling guide o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com