Raw material mixing and smelting device for refractory brick

A technology of refractory bricks and raw materials, applied in the field of refractory bricks, can solve the problems affecting the use effect, damage, deformation, etc., and achieve the effect of reducing the impact of impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

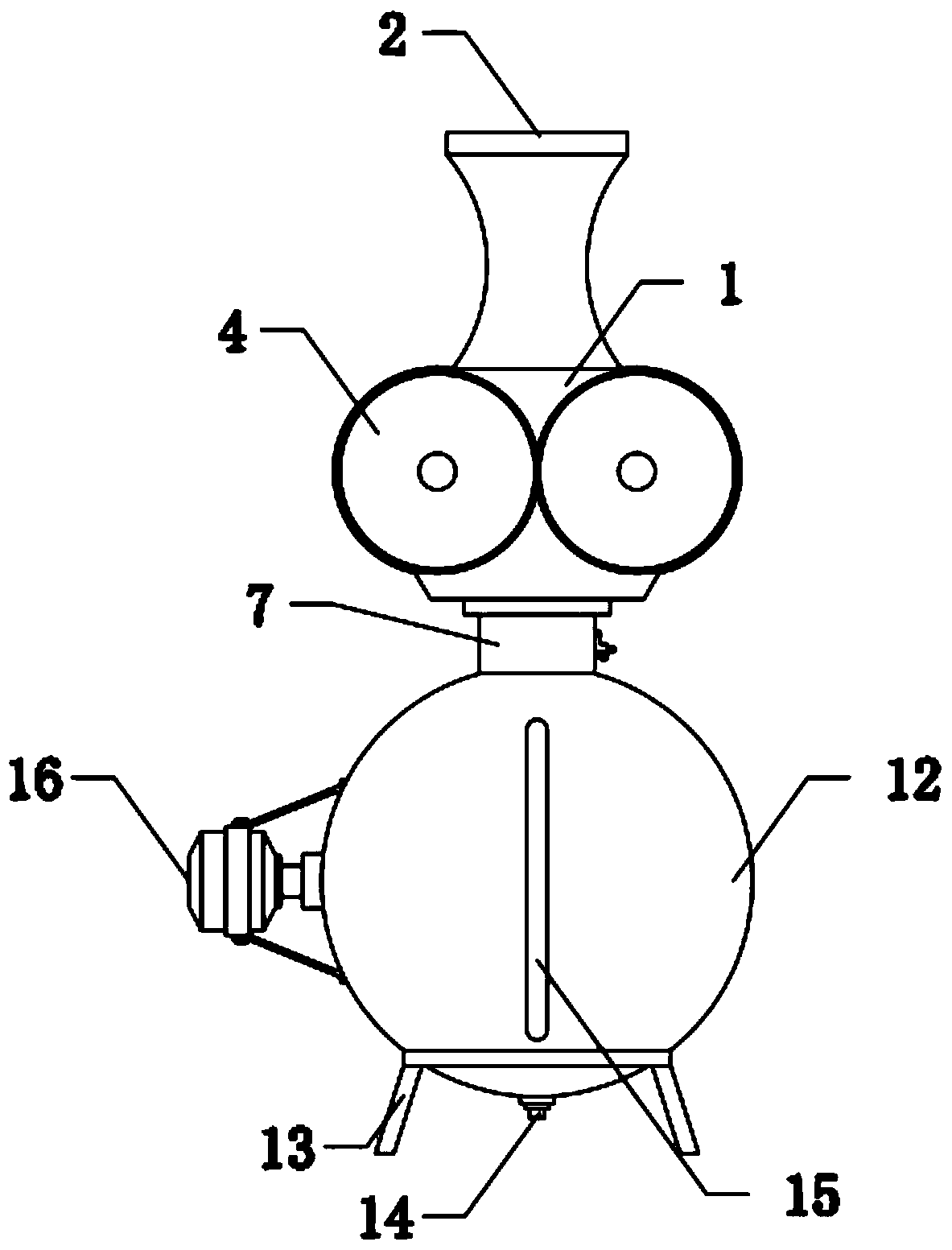

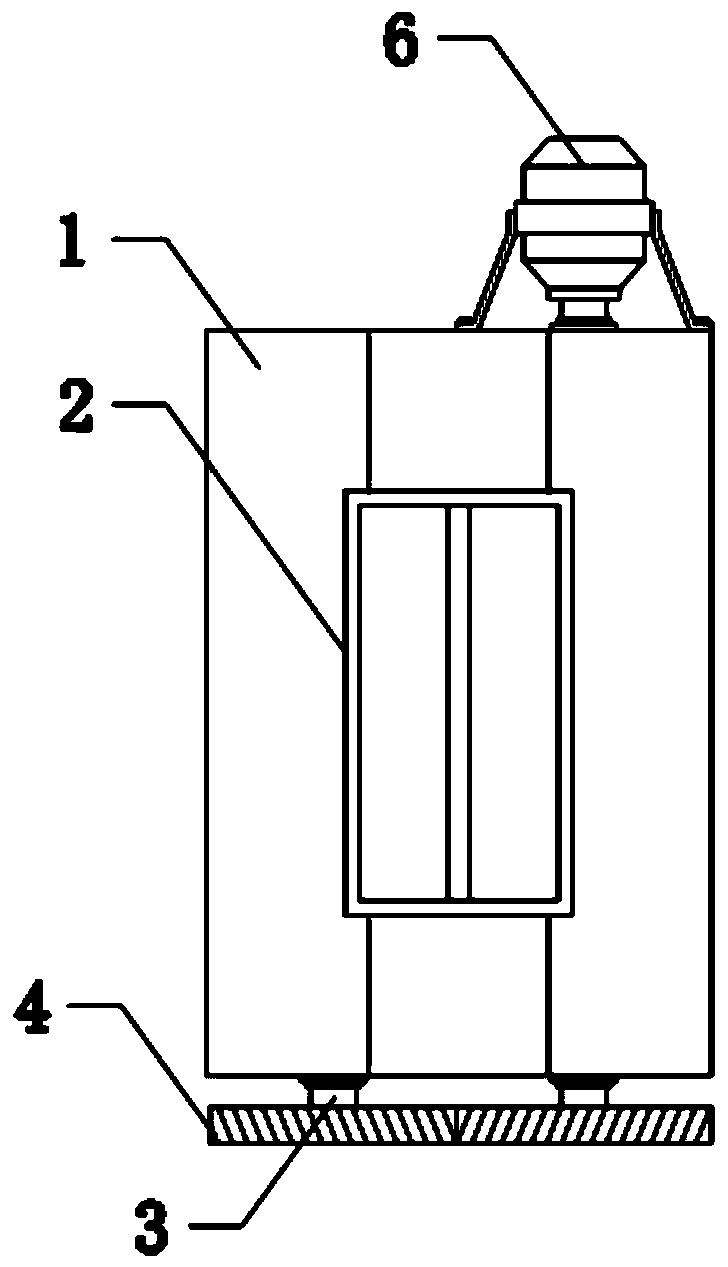

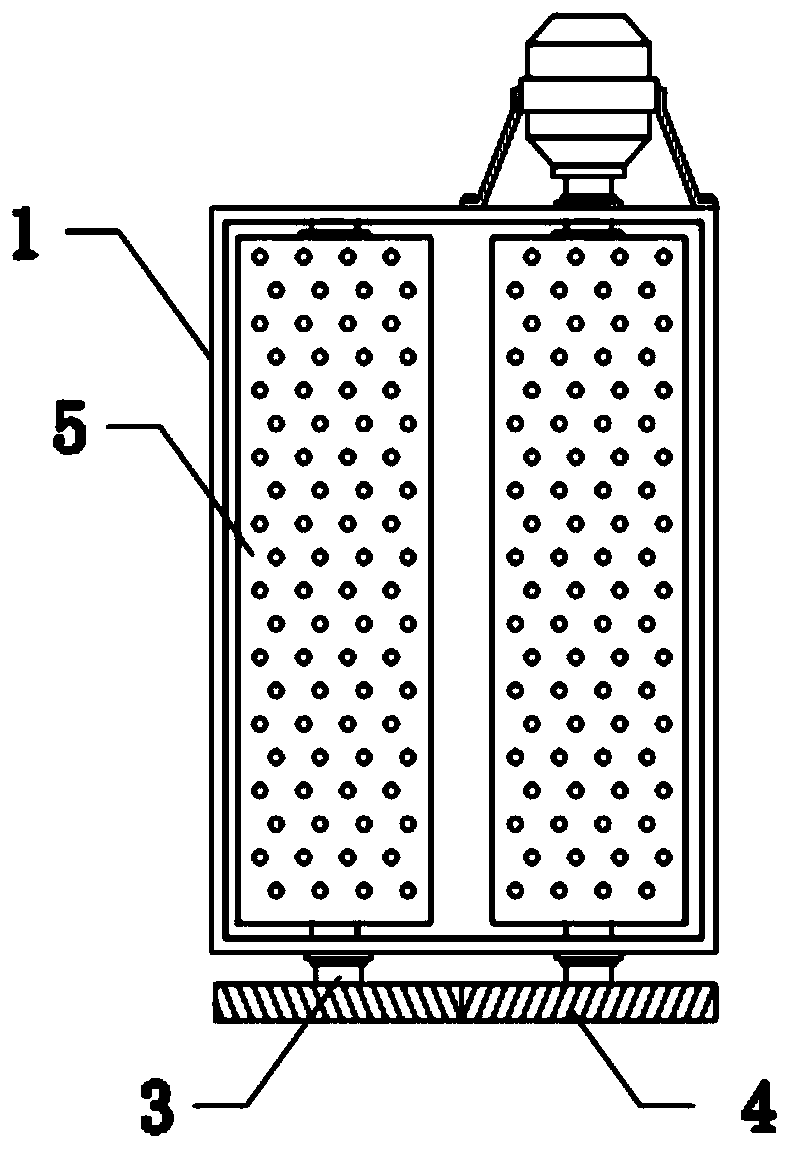

[0029] see Figure 1-6 , the present invention provides a technical solution: a raw material mixing device for refractory bricks, including a crushing chamber 1, the upper end of the crushing chamber 1 is connected with a feed port 2, and the feed port 2 and the inner cavity of the crushing chamber 1 Connected, the material is added through the feed port 2 and enters the inner cavity of the crushing cavity 1;

[0030] The inner cavity of the crushing chamber 1 is radially installed with two crushing shafts 3 through bearings, the front ends of the two crushing shafts 3 extend to the front side of the crushing chamber 1, and the front ends of the two crushing shafts 3 are installed with Gear 4, and the two gears 4 mesh with each other, the rear end of the crushing shaft 3 on the right is connected to the rotor shaft of the crushing drive motor 6, and the crushing drive motor 6 is connected to the rear side of the crushing chamber 1 through the motor bracket wall connection, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap