Material lifting device

A material and material trough technology, used in loading/unloading, transportation and packaging, conveyors, etc., to achieve uniform feeding, prevention of overloaded transportation, and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention;

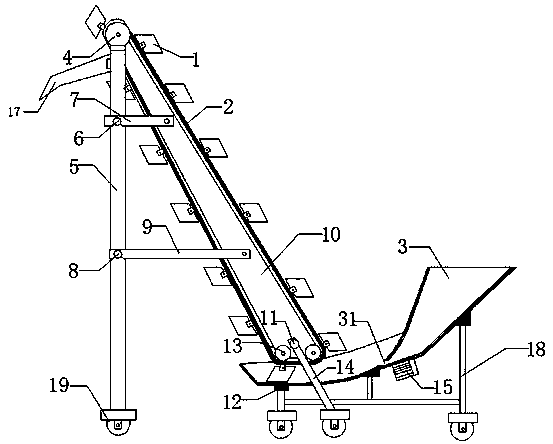

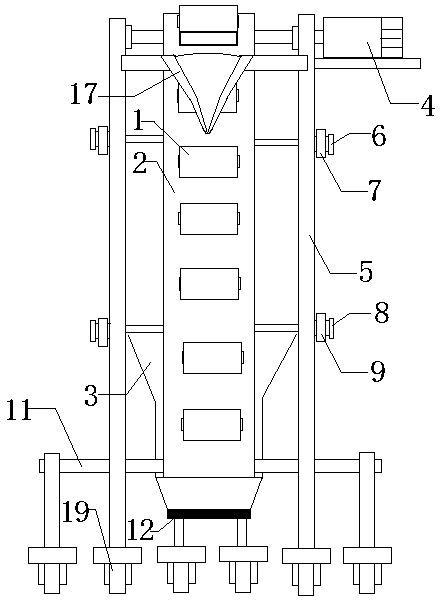

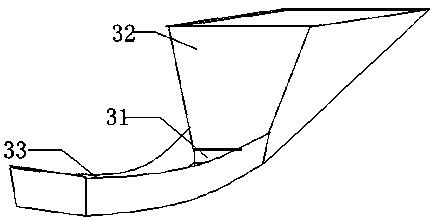

[0022] Such as figure 1 , 2 As shown, a material lifting device includes a material box 1, a chain 2, a material tank 3, a motor 4, a support rod 5, a transverse rib A7, a transverse rib B9, an inner lining frame 10, a transverse bar 11, a sprocket 13, a brace Rod 14; the inner lining frame 10 is arranged obliquely, the two sides of the upper end are connected and supported by two support rods 5, and the two sides of the lower end are supported by two diagonal braces 14 connected by a cross bar 11; the upper end of the inner lining frame 10 is installed There is a sprocket 13, and two sprockets 13 are installed in parallel at the lower end; the chain 2 is arranged on the three sprockets 13; the upper end of the support rod 5 is also equipped with a motor 4 (a reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com