Base band sheet-pulling device for processing conducting copper foil adhesive tape

A technology of adhesive tape and base tape, which is applied in the directions of transportation and packaging, winding strips, sending objects, etc. It can solve the problems of low processing efficiency and slow pulling speed, so as to improve work efficiency, prevent the base tape from loosening, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

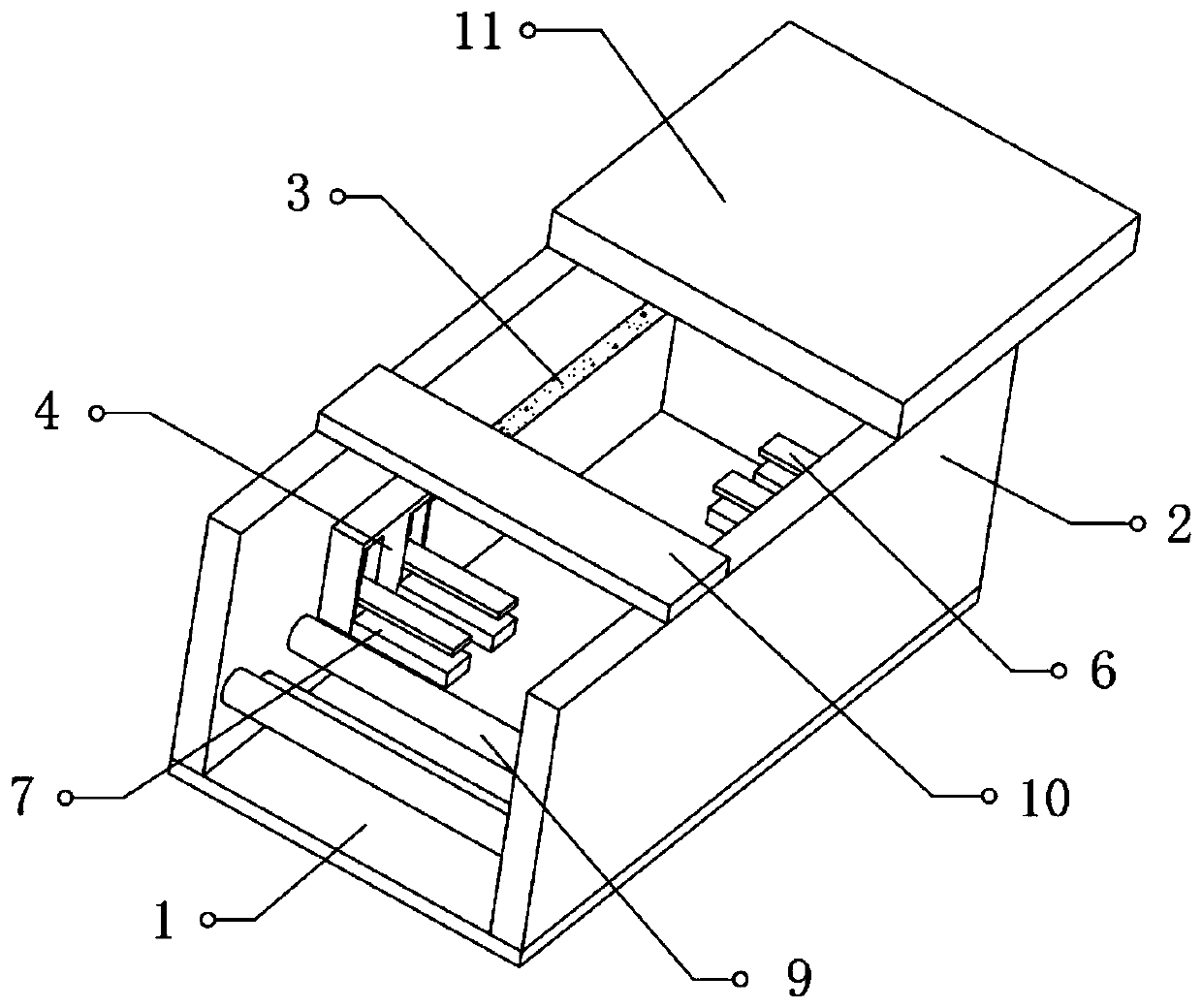

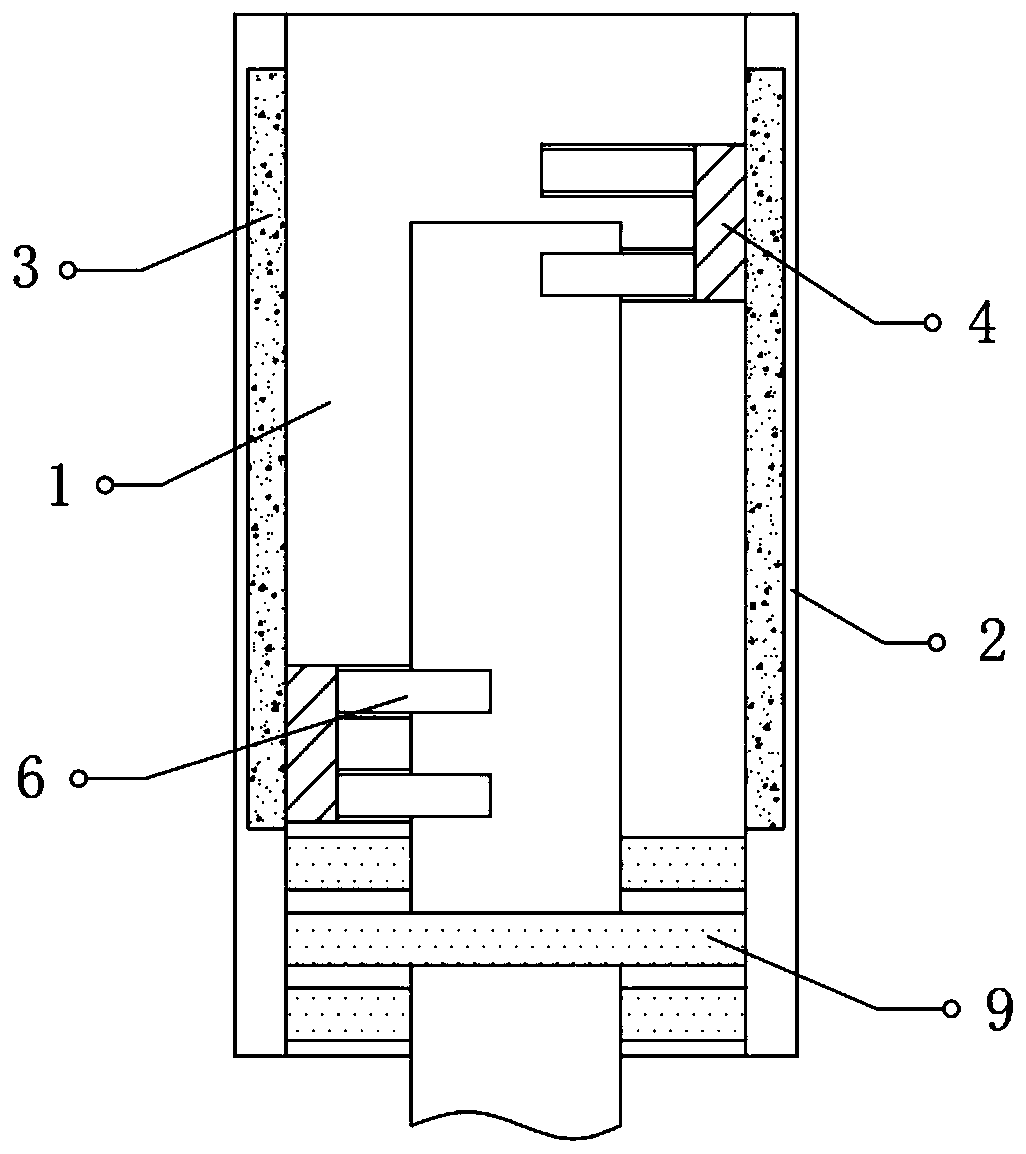

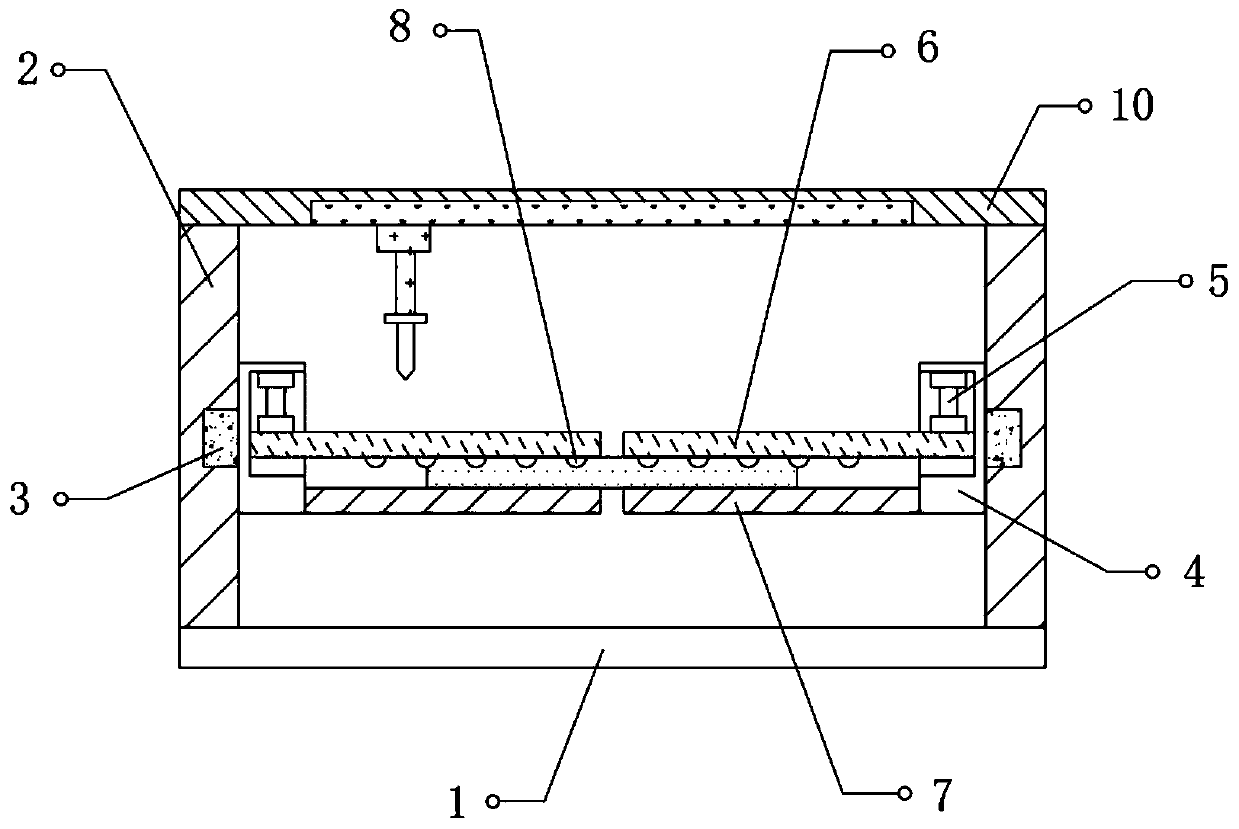

[0024] refer to Figure 1-3 , a base tape pull-tab device for conductive copper foil tape processing, including a base 1, a fixing frame 2 is fixed at both ends of the top outer wall of the base 1, and a first electric guide rail 3 arranged horizontally is fixed at one end of the fixing frame 2, the second One end of an electric guide rail 3 is connected with a clamping mechanism, and the sum of the widths of the two clamping mechanisms is less than the width between the two fixed frames 2, and the same cutting frame 10 is fixed on one side of the top of the two fixed frames 2 , and the bottom of the cutting frame 10 is provided with a cutting mechanism, the other side of the top of the two fixed frames 2 is fixed with the same retrieving frame 11, and the bottom of the retrieving frame 11 is provided with a retrieving mechanism.

[0025] In the present invention, the cutting mechanism is provided with a second electric guide rail fixed on the bottom of the cutting frame 10, a...

Embodiment 2

[0030] refer to Figure 1-2 with Figure 4 , a base tape pull-tab device for conductive copper foil tape processing, further, a mounting groove is opened on the top outer wall of the support plate 7, and a vacuum chuck 12 is fixed on the inner wall of the mounting groove.

[0031] Working principle: Further, the device is provided with an installation slot on the top of the support plate 7, and a vacuum suction cup 12 is fixed in the installation slot to connect with the vacuum pump through the air pipe, so that when the support plate 7 and the pressure plate 6 are used to clamp the base tape, the vacuum suction cup 12 is used to clamp the base tape. The adsorption effect on the baseband enhances the stability of the baseband being clamped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com