Preparation method of lignin-based carbon material rich in meso-pores or meso-pores and macro-pores

A lignin-based, lignin-based technology, applied in the field of renewable carbon materials, can solve the problems that the mesopore size of carbon materials is difficult to be effectively controlled, it is difficult to achieve timely and effective pore regulation, and the price is high, so as to be beneficial to the utilization and the environment Protection, good catalytic carbonization, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Present embodiment technological step is as follows:

[0035] (1) Dissolve 4g calcium lignosulfonate in 8mL deionized water to make a lignin solution, then add 4g calcium chloride into the lignin solution under stirring, when the calcium chloride is completely dissolved and mixed evenly, lignin is formed and a mixed solution of calcium chloride, the mixed solution was vacuum-dried at 60°C for 24 hours, and then dried at normal pressure and 105°C for 24 hours to form a solid billet;

[0036] (2) calcining the solid billet obtained in step (1) at 700° C. for 4 hours in a nitrogen atmosphere, and cooling to room temperature after the calcination to obtain a carbon material containing calcium chloride;

[0037] (3) Soak and wash the calcium chloride-containing carbon material obtained in step (2) with deionized water to remove calcium chloride. The specific operation is: put the calcium chloride-containing carbon material into 20 mL of deionized water for once soaking and w...

Embodiment 2

[0043] Present embodiment technological step is as follows:

[0044] (1) Dissolve 4g of calcium lignosulfonate in 8mL of deionized water to make a lignin solution, then add 2g of calcium chloride into the lignin solution under stirring, when the calcium chloride is completely dissolved and mixed evenly, lignin is formed and a mixed solution of calcium chloride, the mixed solution was vacuum-dried at 80°C for 24h, and then dried at normal pressure and 105°C for 24h to form a solid billet;

[0045] (2) calcining the solid billet obtained in step (1) at 700° C. for 2 hours in a nitrogen atmosphere, and cooling to room temperature after the calcination to obtain a carbon material containing calcium chloride;

[0046] (3) This step is the same as in Example 1.

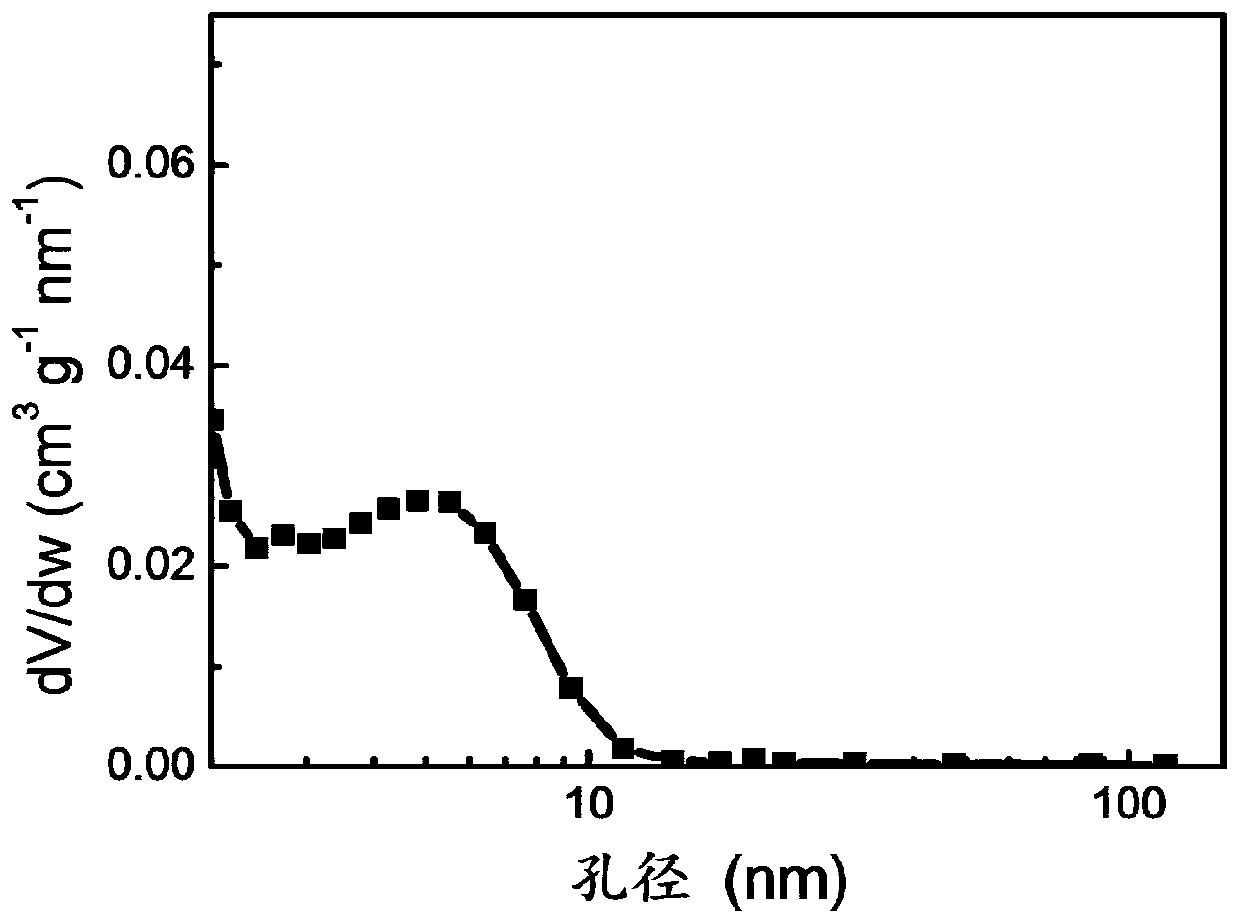

[0047] The appearance of the lignin-based carbon material prepared in this example is similar to that of the lignin-based carbon material prepared in Example 1. The lignin-based carbon material prepared in this example wa...

Embodiment 3

[0049] Present embodiment technological step is as follows:

[0050] (1) Dissolve 4g of calcium lignosulfonate in 8mL of deionized water to prepare a lignin solution, then add 6g of calcium chloride into the lignin solution under stirring, when the calcium chloride is completely dissolved and mixed evenly, lignin is formed and a mixed solution of calcium chloride, the mixed solution was vacuum-dried at 50°C for 24h, and then dried at normal pressure and 105°C for 24h to form a solid billet;

[0051] (2) calcining the solid billet obtained in step (1) at 700° C. for 6 hours in a nitrogen atmosphere, and cooling to room temperature after the calcination to obtain a carbon material containing calcium chloride;

[0052] (3) This step is the same as in Example 1.

[0053] The appearance of the lignin-based carbon material prepared in this example is similar to that of the lignin-based carbon material prepared in Example 1. The lignin-based carbon material prepared in this example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com