Cement-based waterborne epoxy mortar, and preparation method and application thereof

A technology of epoxy mortar and water-based epoxy, which is applied in the field of building materials, can solve the problems that cannot fully meet the application requirements of cement composite materials, affect the construction period of the floor, affect the adhesion of floor paint, etc., and achieve good hydrophobicity and resistance. Permeability, increase internal compactness, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

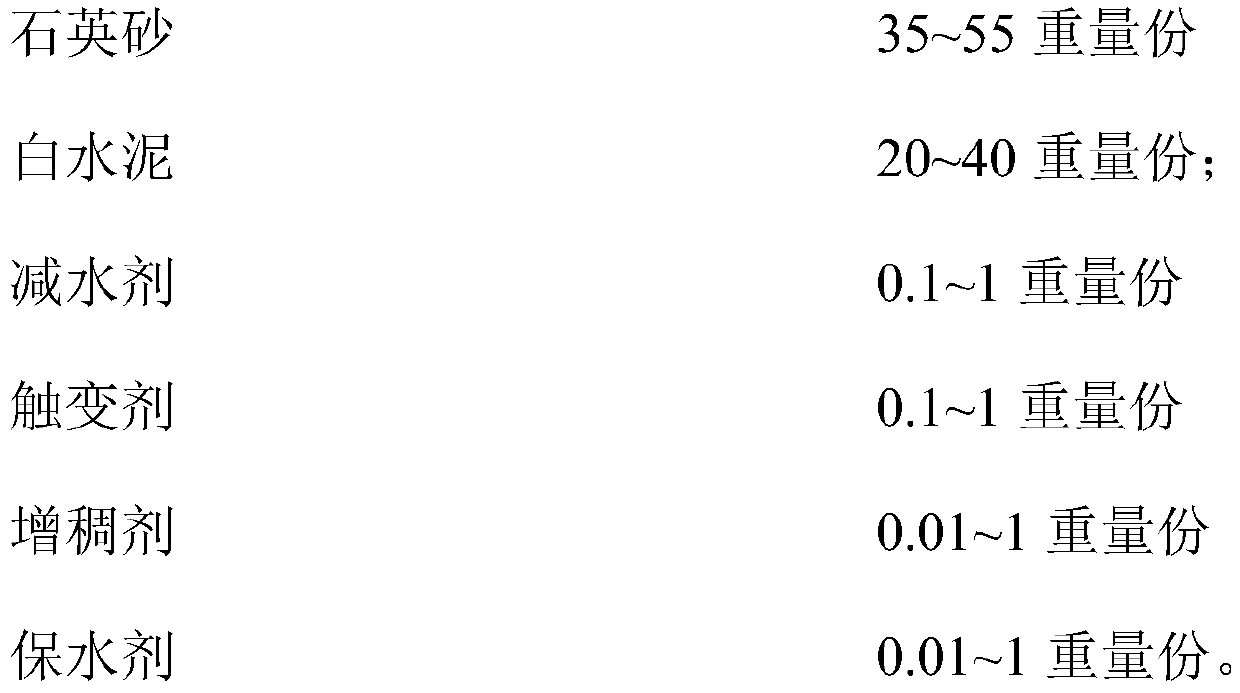

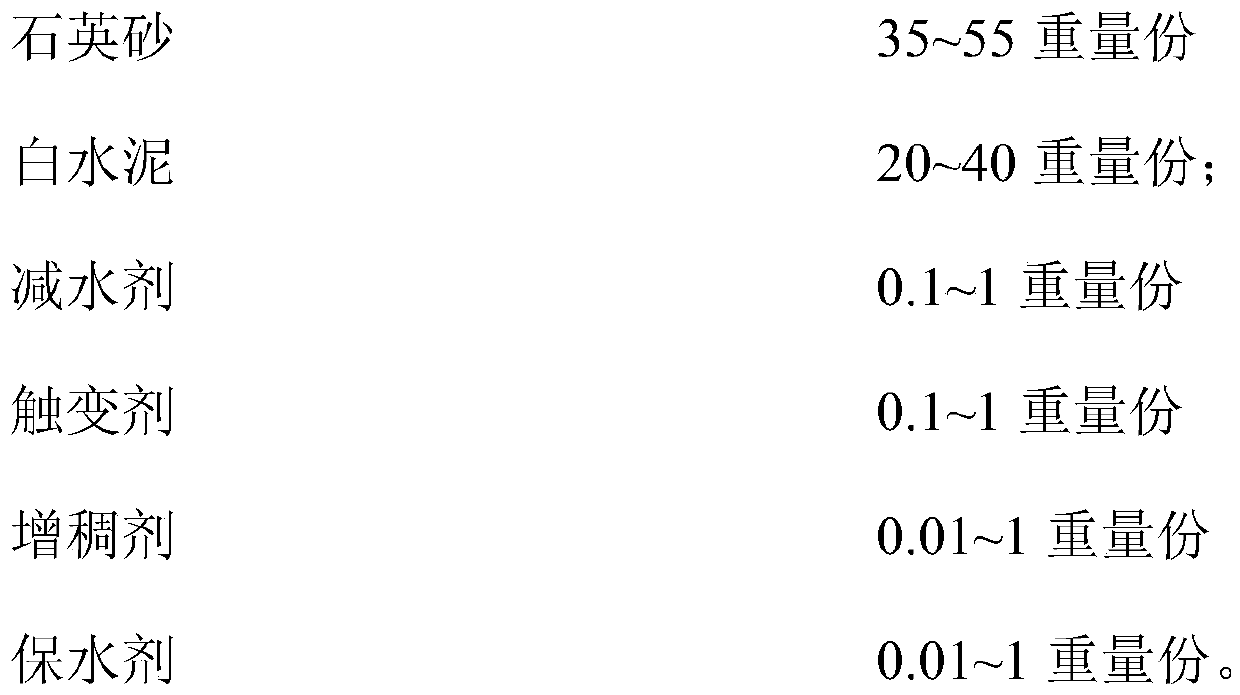

[0079] The present embodiment provides a cement-based water-based epoxy mortar, the formula is as follows:

[0080] Component A: 5 parts by weight of water-based epoxy emulsion, 5 parts by weight of silicone hydrophobic emulsion;

[0081] Component B: 3 parts by weight of water-based epoxy curing agent, 0.05 parts by weight of defoamer, and 8.2 parts by weight of water;

[0082] Component C: 44 parts by weight of quartz sand, 33 parts by weight of white cement, 0.25 parts by weight of water reducer, 0.1 part by weight of defoamer, 0.65 parts by weight of expansion agent, 0.4 parts by weight of thixotropic agent, 0.08 parts by weight of thickener, 0.03 parts by weight of water-retaining agent, 0.24 parts by weight of early strength agent;

[0083] The preparation method is as follows: mix the components in component A, component B and component C separately, and disperse uniformly; then mix component A and component B, disperse uniformly, and then add component C to obtain the...

Embodiment 2

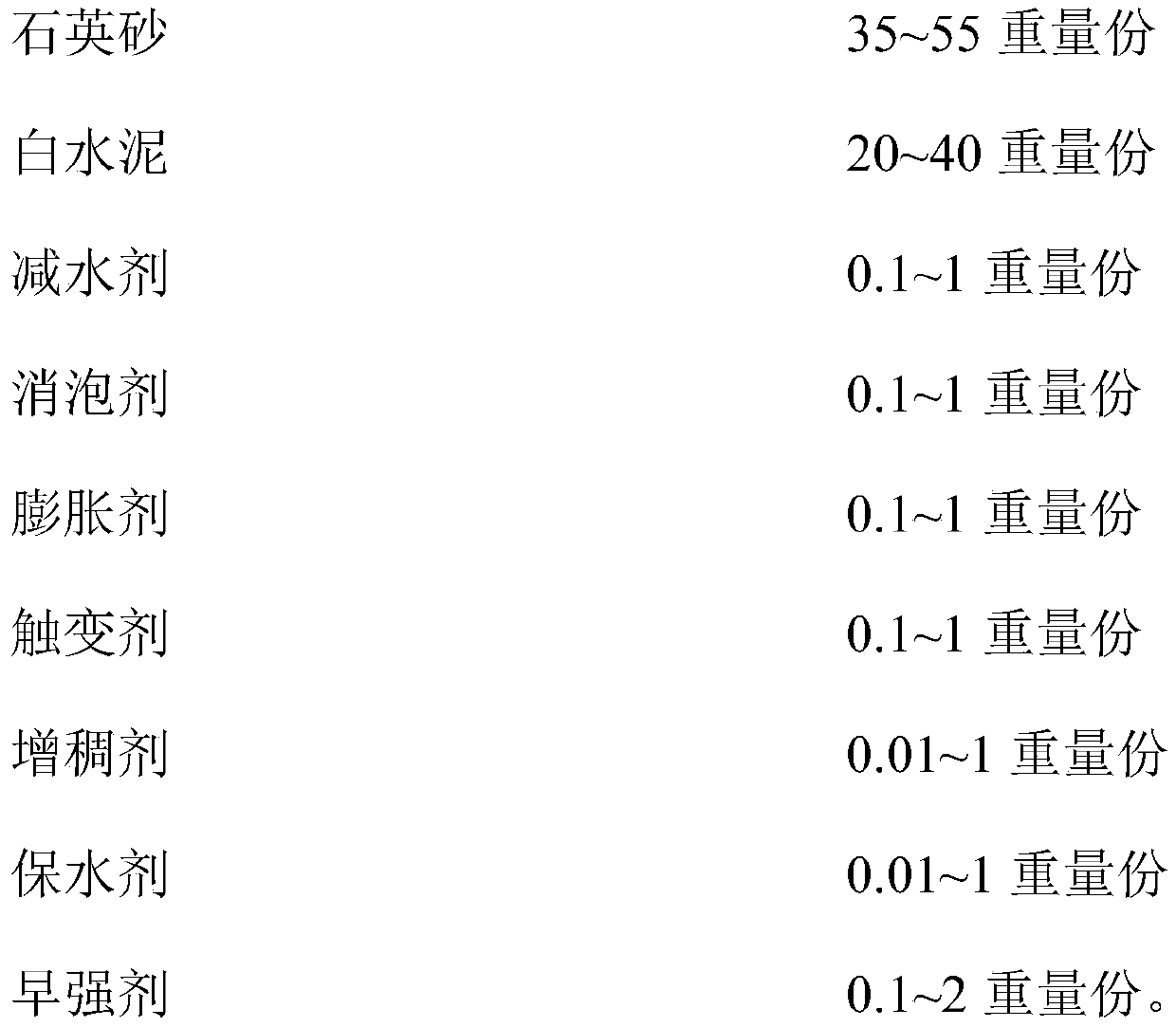

[0085] The present embodiment provides a cement-based water-based epoxy mortar, the formula is as follows:

[0086] Component A: 3 parts by weight of water-based epoxy emulsion, 8 parts by weight of silicone hydrophobic emulsion;

[0087] Component B: 1.8 parts by weight of water-based epoxy curing agent, 0.01 parts by weight of defoamer, and 8.6 parts by weight of water;

[0088] Component C: 37 parts by weight of quartz sand, 40 parts by weight of white cement, 0.3 parts by weight of water reducer, 0.1 part by weight of defoamer, 0.57 parts by weight of expansion agent, 0.1 part by weight of thixotropic agent, and 0.01 part by weight of thickener, 0.01 parts by weight of water retaining agent, 0.5 parts by weight of early strength agent;

[0089] The preparation method is the same as in Example 1.

Embodiment 3

[0091] The present embodiment provides a cement-based water-based epoxy mortar, the formula is as follows:

[0092] Component A: 8 parts by weight of water-based epoxy emulsion, 3 parts by weight of silicone hydrophobic emulsion;

[0093] Component B: 4 parts by weight of water-based epoxy curing agent, 0.1 part by weight of defoamer, and 8.6 parts by weight of water;

[0094] Component C: 55 parts by weight of quartz sand, 20 parts by weight of white cement, 0.15 parts by weight of water reducer, 0.1 part by weight of defoamer, 0.35 parts by weight of expansion agent, 0.35 parts by weight of thixotropic agent, and 0.08 parts by weight of thickener, 0.03 parts by weight of water-retaining agent, 0.24 parts by weight of early strength agent;

[0095] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com