Assembled gravity type flanged suction caisson foundation

A caisson foundation, suction-type technology, applied in the direction of infrastructure engineering, protection devices, buildings, etc., can solve the problems of uneconomical, increased cost, time-consuming, etc., to improve the vertical and horizontal bearing capacity, ensure the overall stability, The effect of improving engineering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

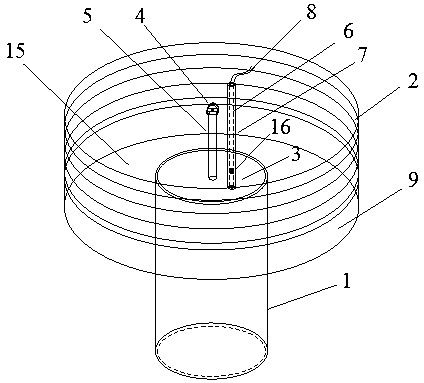

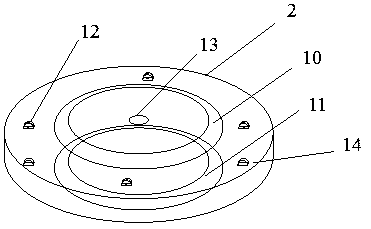

[0023] Such as figure 1 Shown: an assembled gravity-type winged suction caisson foundation, including winged suction caisson foundation 1; wherein the bottom of the winged suction caisson foundation 1 is provided with an opening and the top is provided with a cover 3 and a steel plate; wherein The cover 3 is provided with a steel column 5, a steel casing 7 and a drainage channel 6; wherein the steel plate is successively provided with several prefabricated concrete weights 2; the top of each prefabricated concrete weight 2 is provided with There is a frustum-shaped convex groove 10 and a frustum-shaped groove 11 at the bottom, and each two adjacent prefabricated concrete weights 2 are superimposed on each other through the frustum-shaped convex groove 10 and the conical groove 11; wherein the winged The upper part of the side of the suction caisson foundation 1 is provided with an annular flange 9,

[0024] The drainage channel 6 is located in the steel casing 7 and one end t...

Embodiment 2

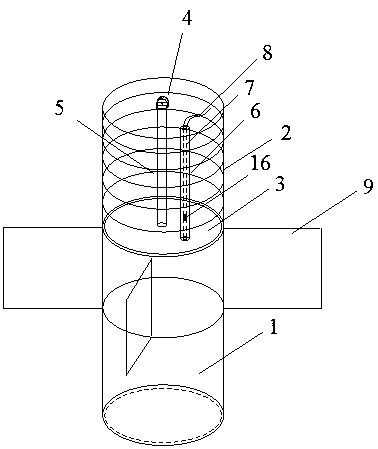

[0028] Such as figure 2 Shown: an assembled gravity-type winged suction caisson foundation, including winged suction caisson foundation 1; wherein the bottom of the winged suction caisson foundation 1 is provided with an opening and the top is provided with a cover 3 and a steel plate; wherein The cover 3 is provided with a steel column 5, a steel casing 7 and a drainage channel 6; wherein the wing suction caisson foundation 1 is successively provided with several prefabricated concrete weights 2; each of the prefabricated concrete weights 2 is equal to the diameter of the winged suction caisson foundation 1.

[0029] The top of each precast concrete weight 2 is provided with a conical convex groove 10 and the bottom is provided with a conical groove 11, and each two adjacent prefabricated concrete weights 2 pass through the conical convex groove 10 and the conical groove. 11 interlocking, connecting and superimposing; wherein the upper part of the side of the winged suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com