Multifunctional tunneling all-in-one machine

An all-in-one, multi-functional technology, applied in slitting machinery, drilling equipment, drilling equipment and methods, etc., can solve the problems of high safety risk, affecting efficiency, low construction efficiency, etc., to reduce volume, ensure stability, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

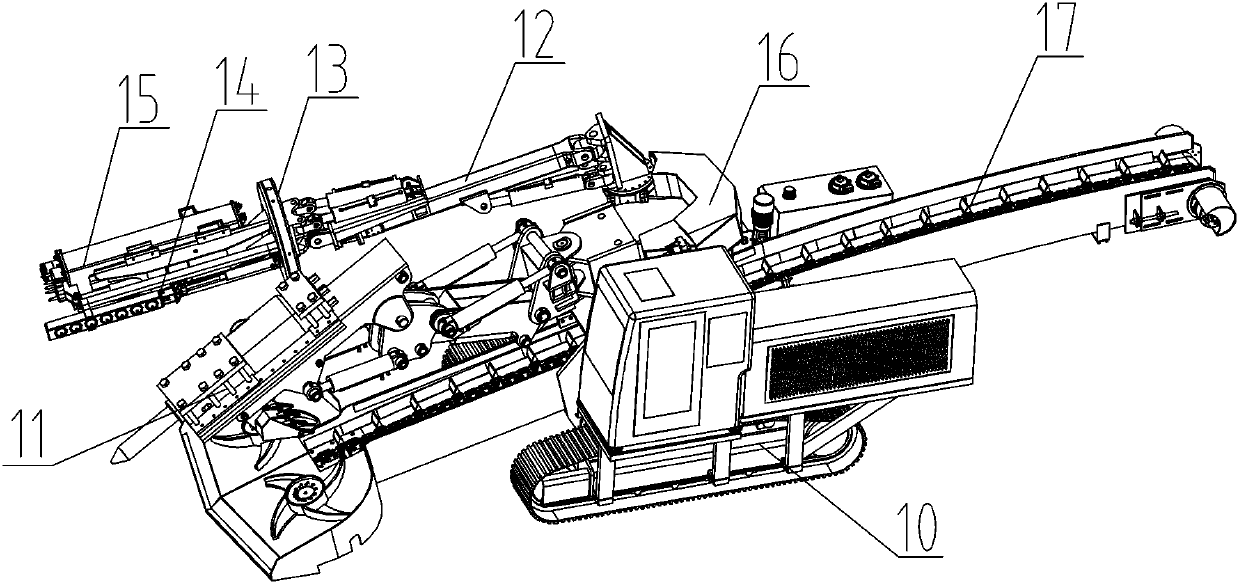

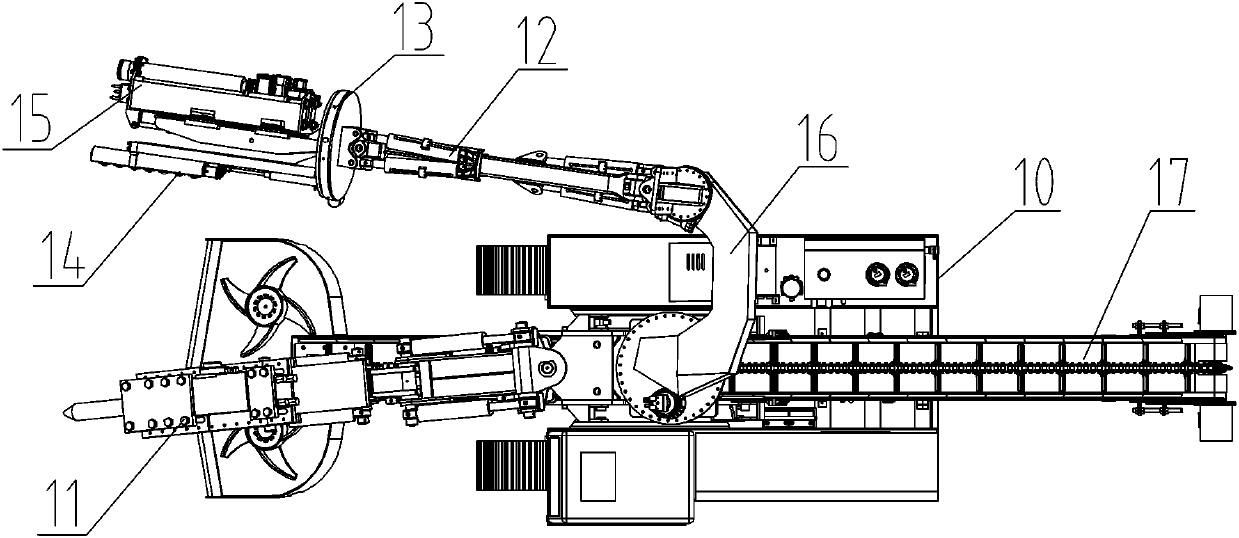

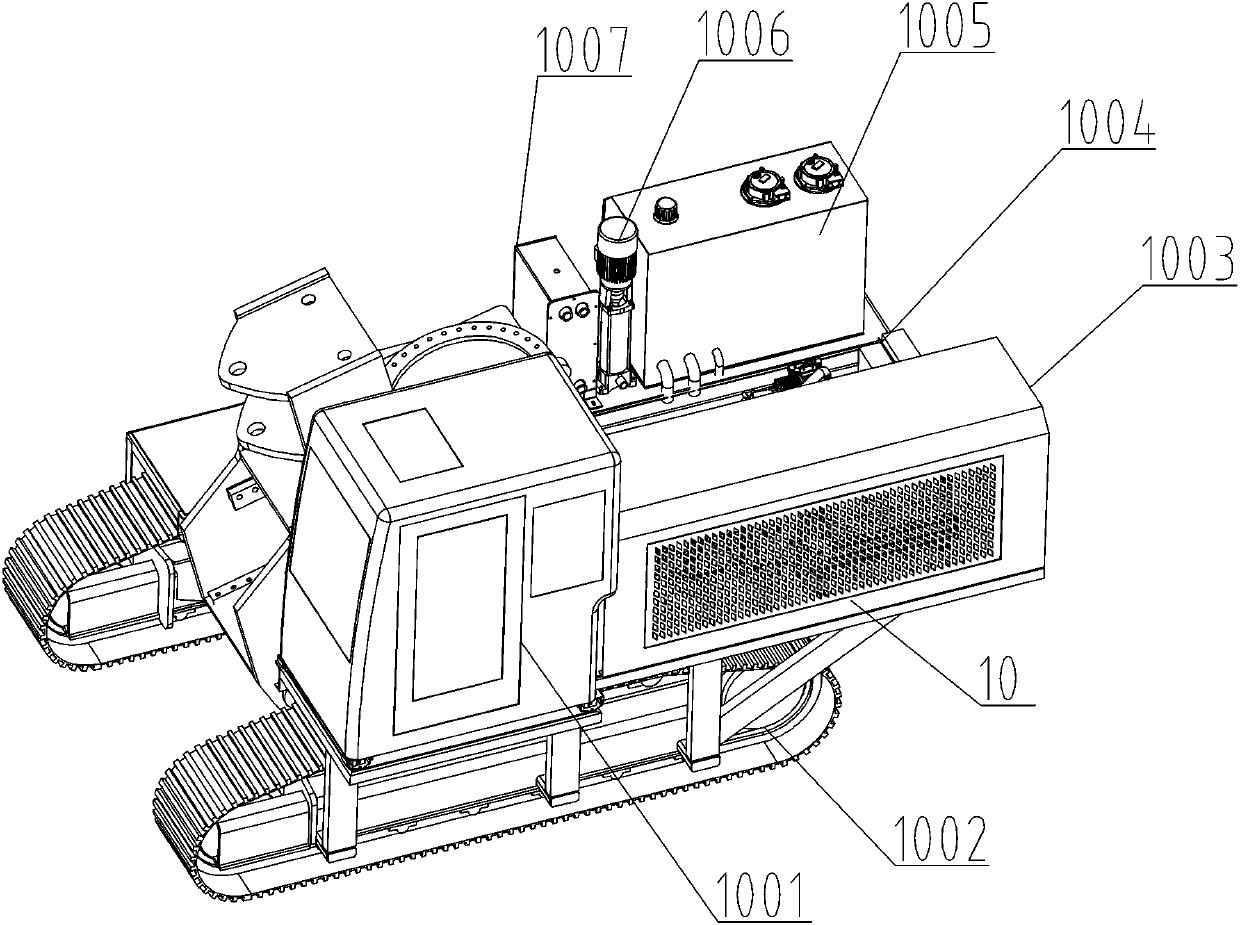

[0075] see Figure 1-19 , a multi-function tunneling machine, which includes a chassis system 10 for carrying the entire device, the middle part of the chassis system 10 is obliquely installed with a conveying mechanism 17 for slag conveying; the head of the chassis system 10 is located at the conveying A crushing and slag removal mechanism 11 for rock mass crushing is installed above the mechanism 17; a working arm 12 is installed on the top of the chassis system 10 through a multi-stage rotary arm mechanism 16, and a rotary speed reduction device 13 is installed at the end of the working arm 12. A drilling device 15 for drilling and a splitting device 14 for splitting rock mass are installed on the end face of the rotary disc of the rotary deceleration device 13 . The all-in-one machine of the above-mentioned device realizes its steering transposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com