Anti-blocking structure of flue gas waste heat utilization system for rotary hearth furnace and anti-blocking method thereof

A flue gas waste heat, rotary hearth furnace technology, applied in combustion methods, furnaces, waste heat treatment and other directions, can solve the problems of difficult operation, limited effect, wide range of smoke and dust bonding temperature, etc. The effect of prolonging the blockage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

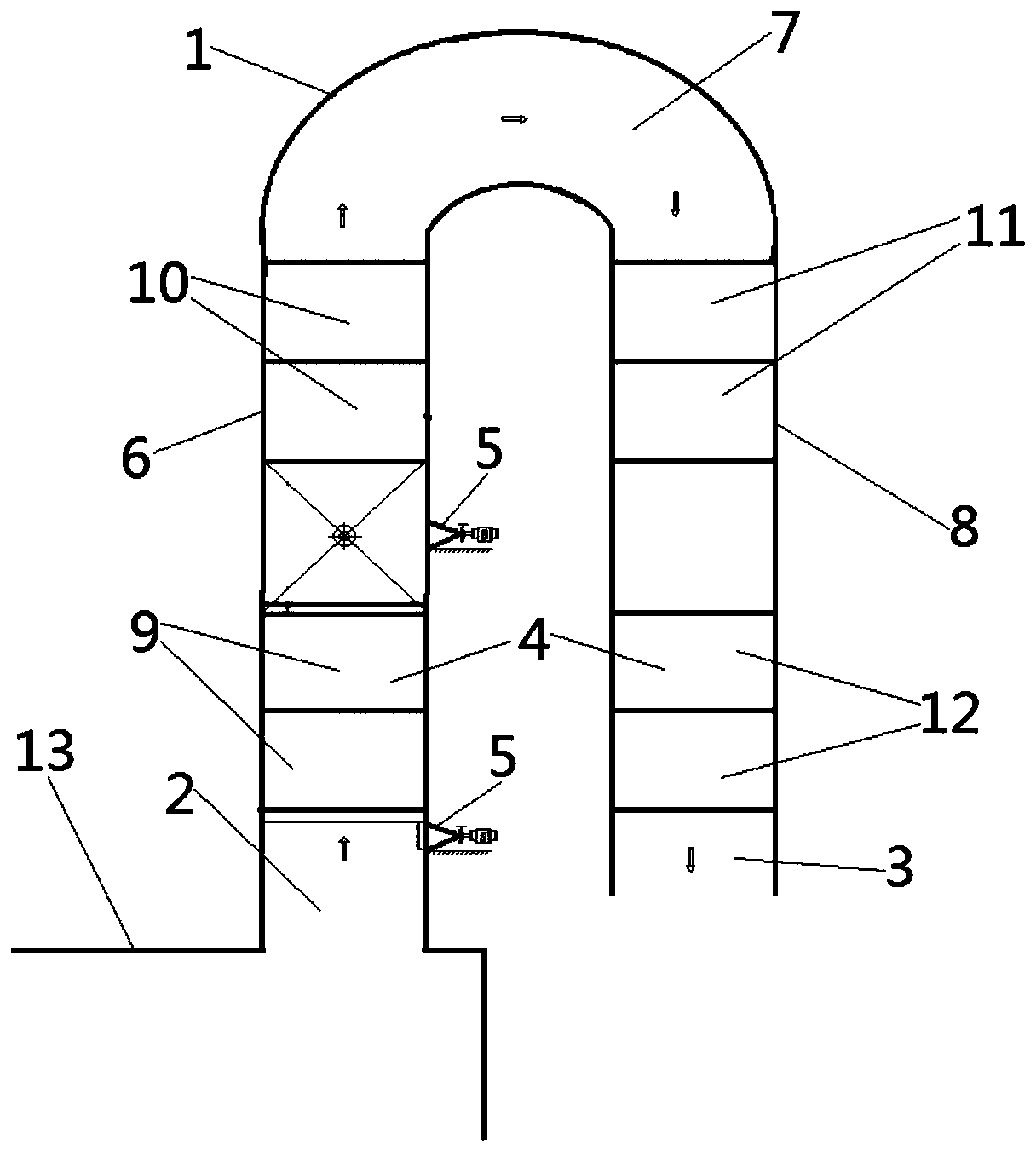

[0035] The anti-blocking structure of the flue gas waste heat utilization system of the rotary hearth furnace according to the present invention, embodiment 1 is:

[0036] The temperature of the flue gas entering the primary heat exchanger of the rotary hearth furnace is 400°C, the emission frequency of the sonic soot blower at the entrance of the primary heat exchanger is 50Hz, and the power of the sonic device is 30,000 acoustic watts; the primary heat exchanger and the secondary heat exchanger The emission frequency of the sonic soot blower installed between the soot blowers is 150Hz, the power of the sonic device is 30,000 sound watts, the maximum sound pressure in the primary heat exchanger is 184dB, the sound pressure around the primary heat exchanger and the secondary heat exchanger Above 150dB, the heat exchanger can be switched in 23 days.

[0037] The anti-blocking structure of the flue gas waste heat utilization system of the rotary hearth furnace according to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com