Oxygen detection system for coke oven gas

A technology for oxygen detection and coke oven gas, which is applied in the field of detection equipment, can solve the problems of inaccurate oxygen sensor measurement and unsustainable detection of oxygen concentration, and achieve the effects of fast detection speed, simple structure, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

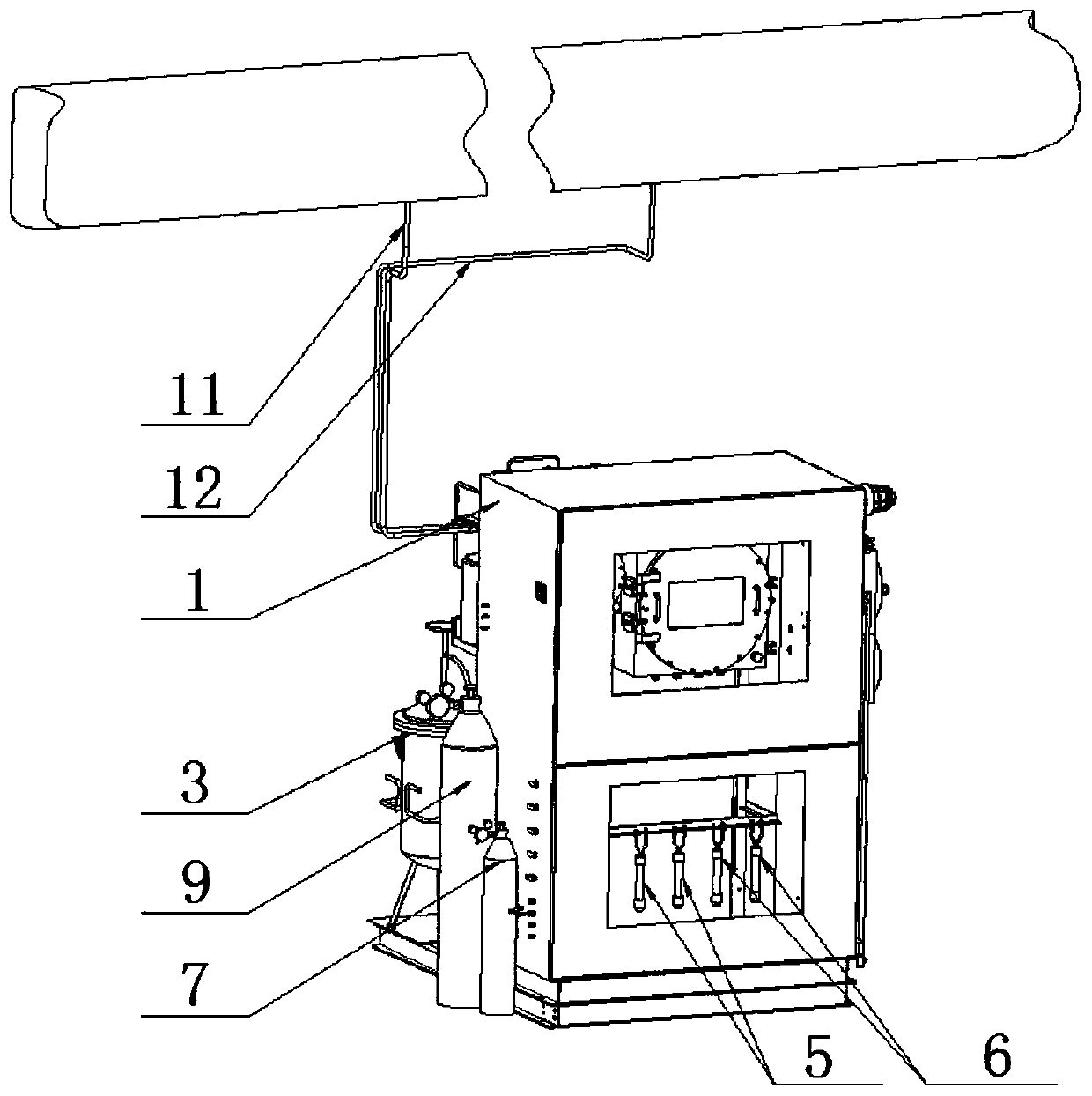

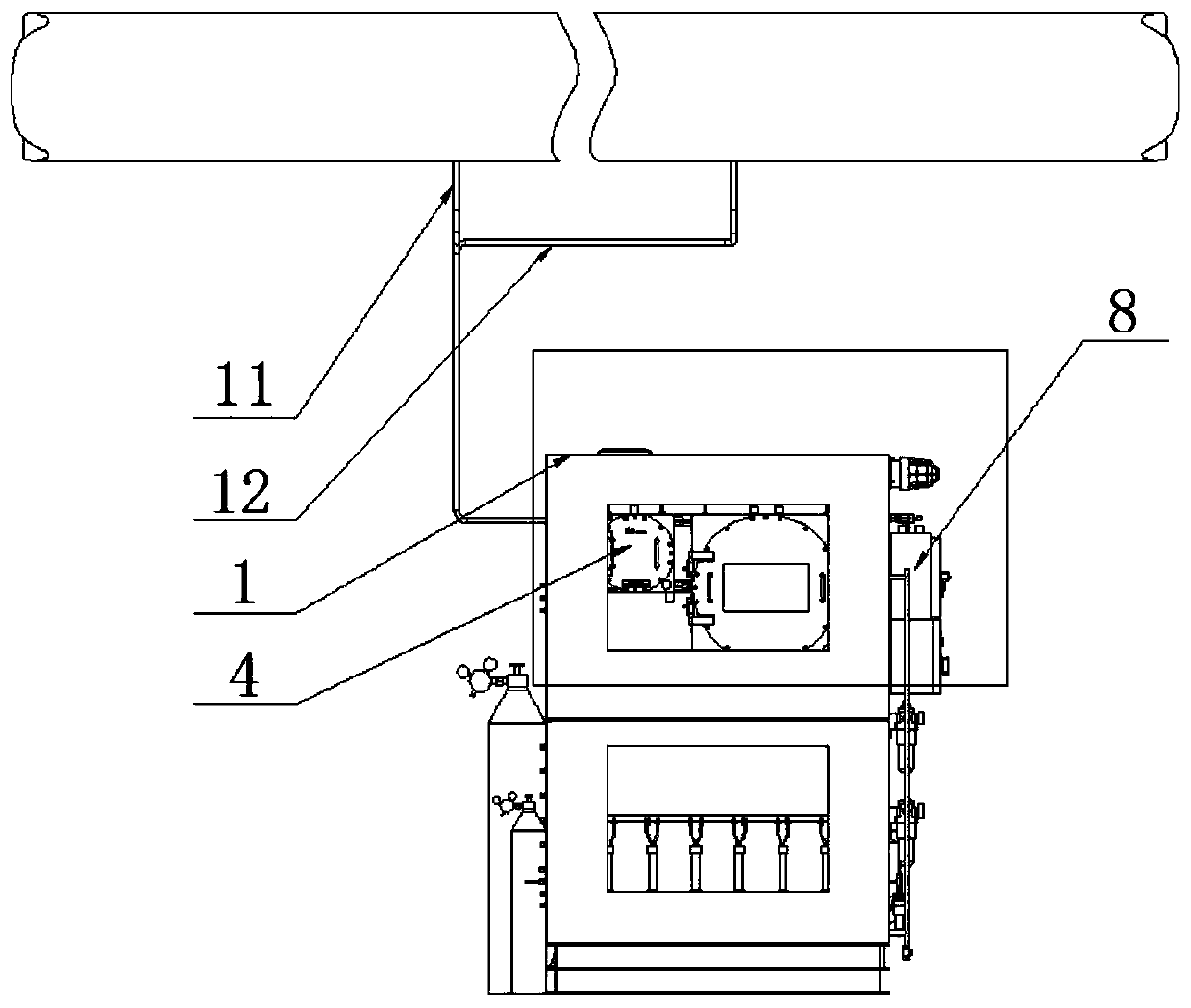

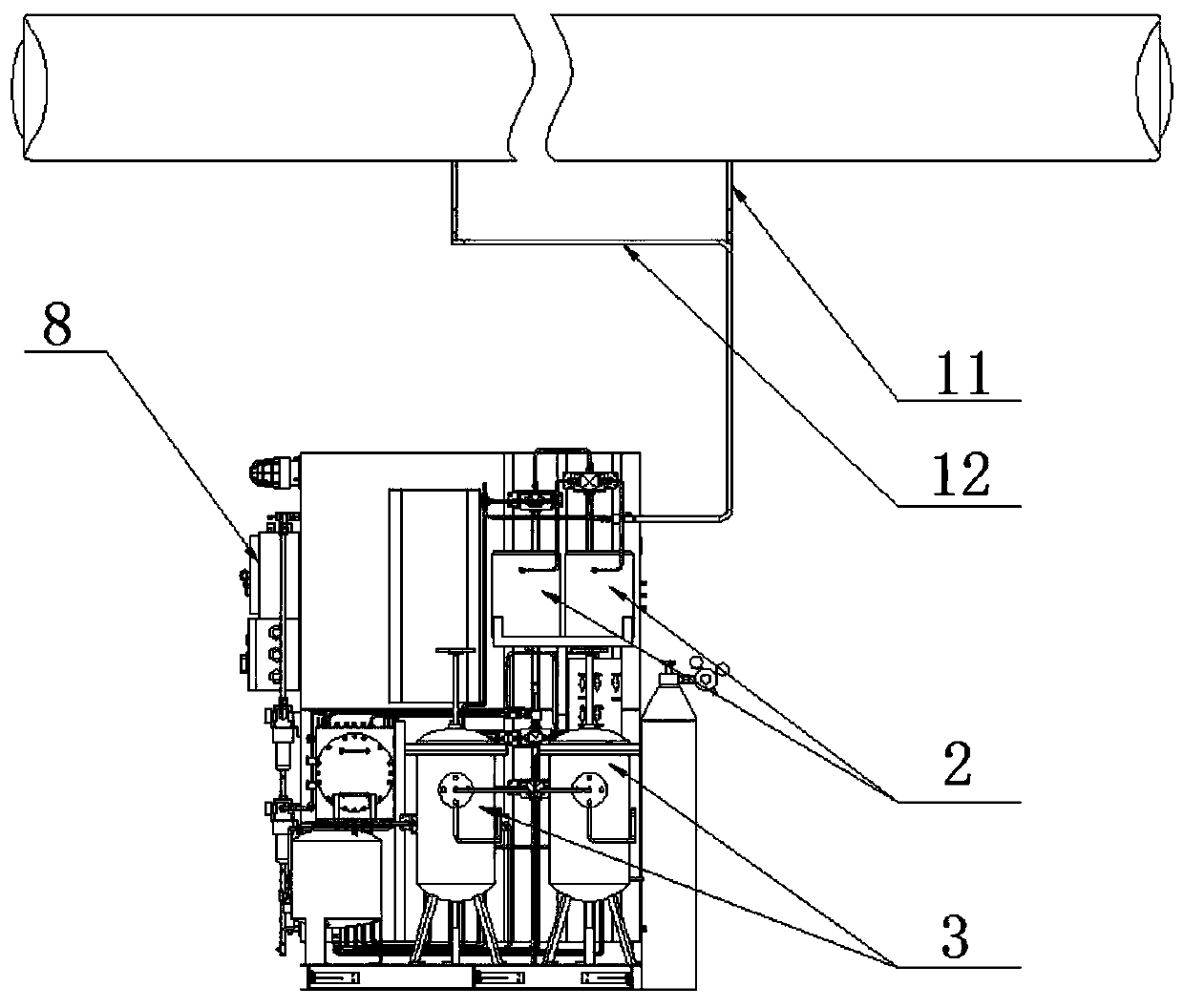

[0043] Such as Figure 1 to Figure 5 As shown, the oxygen detection system for coke oven gas of the present invention includes an inlet pipe 11, an outlet pipe 12 and a sealed explosion-proof cabinet 1, and the explosion-proof cabinet 1 is provided with a cooler 2 and a purifier 3, and the explosion-proof An oxygen detection device 4 is arranged in the cabinet 1, and an oxygen sensor 46 is arranged in the oxygen detection device 4, and the inlet pipe 11 is connected with the outlet pipe 12 through the cooler 2, the purifier 3 and the oxygen detection device 4 in sequence. The cooler 2 includes a first housing 21, a heat exchange cavity 201 is arranged in the first housing 21, a heat exchange tube 202 and a cooling tube 203 are arranged in the heat exchange cavity 201, and a The first air inlet 204 connected to the air inlet pipe 11, the first air outlet 205, the medium port 206 communicating with the heat exchange chamber 201, the cold air inlet 207 and the cold air outlet 208...

Embodiment 2

[0046] This embodiment is a further improvement made on the basis of Embodiment 1, as Figure 6 As shown, the explosion-proof cabinet 1 is also provided with a separation device 5, and the purifier 3 is connected to the oxygen detection device 4 through the separation device 5; the separation device 5 includes a detachable third housing, and the third The housing includes a third upper end cap 51, a third lower end cap 53 and a third cylinder 52 arranged between the third upper end cap 51 and the third lower end cap 53, the third cylinder 52 is filled with color-changing silica gel 54 , the third upper end cover 51 is provided with a third air inlet 55 and a third air outlet 56 .

[0047] Working principle: The coke oven gas treated by the purifier enters the separation device again, and the discoloration silica gel in the separation device can separate out tar, moisture and other substances in the coke oven gas again, and the water will change color after contacting with the ...

Embodiment 3

[0049] This embodiment is a further improvement made on the basis of Embodiment 2, as Figure 7 As shown, the explosion-proof cabinet 1 is also provided with an adsorption device 6, and the separation device 5 is connected with the oxygen detection device 4 through the adsorption device 6; the adsorption device 6 includes a detachable fourth housing, and the fourth The housing includes a fourth upper end cap 61, a fourth lower end cap 63 and a fourth cylinder 62 arranged between the fourth upper end cap 61 and the fourth lower end cap 63, the fourth cylinder 62 is filled with absorbent cotton 64 , the fourth upper end cover 61 is provided with a fourth air inlet 65 and a fourth air outlet 66 .

[0050] Working principle: The coke oven gas treated by the separation device enters the adsorption device again, and the adsorption cotton in the adsorption device can filter out the impurities and moisture in the coke oven gas again, so that the coke oven gas is more pure, convenient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com