Photovoltaic module cleaning robot contact solar storage fast charging system

A technology for cleaning robots and photovoltaic modules, applied in photovoltaic power generation, photovoltaic modules, current collectors and other directions, can solve the problems of slow wireless charging charging rate, insufficient battery life, long cycle, etc., to achieve uncertain charging time, improve charging speed, storage Powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

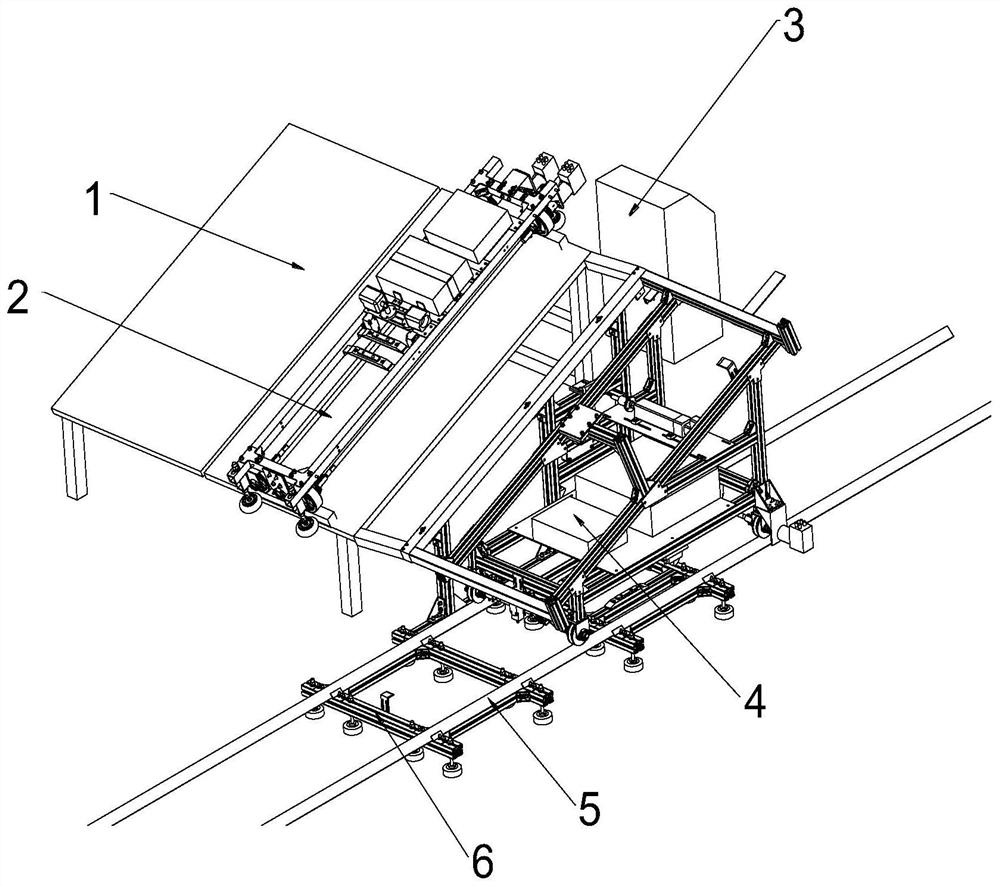

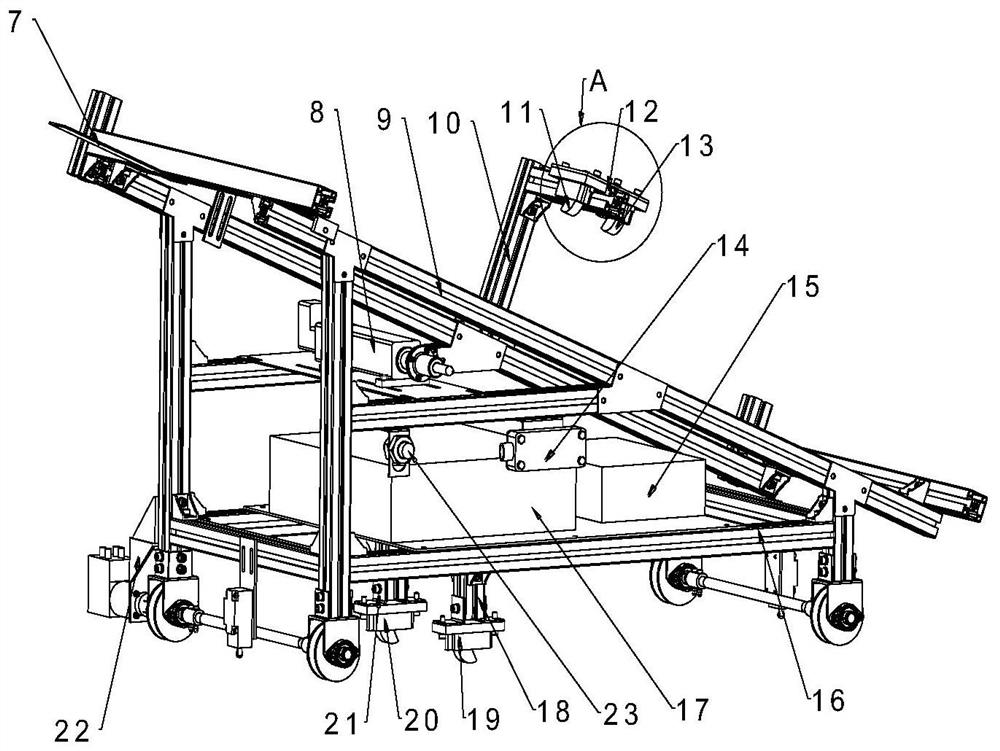

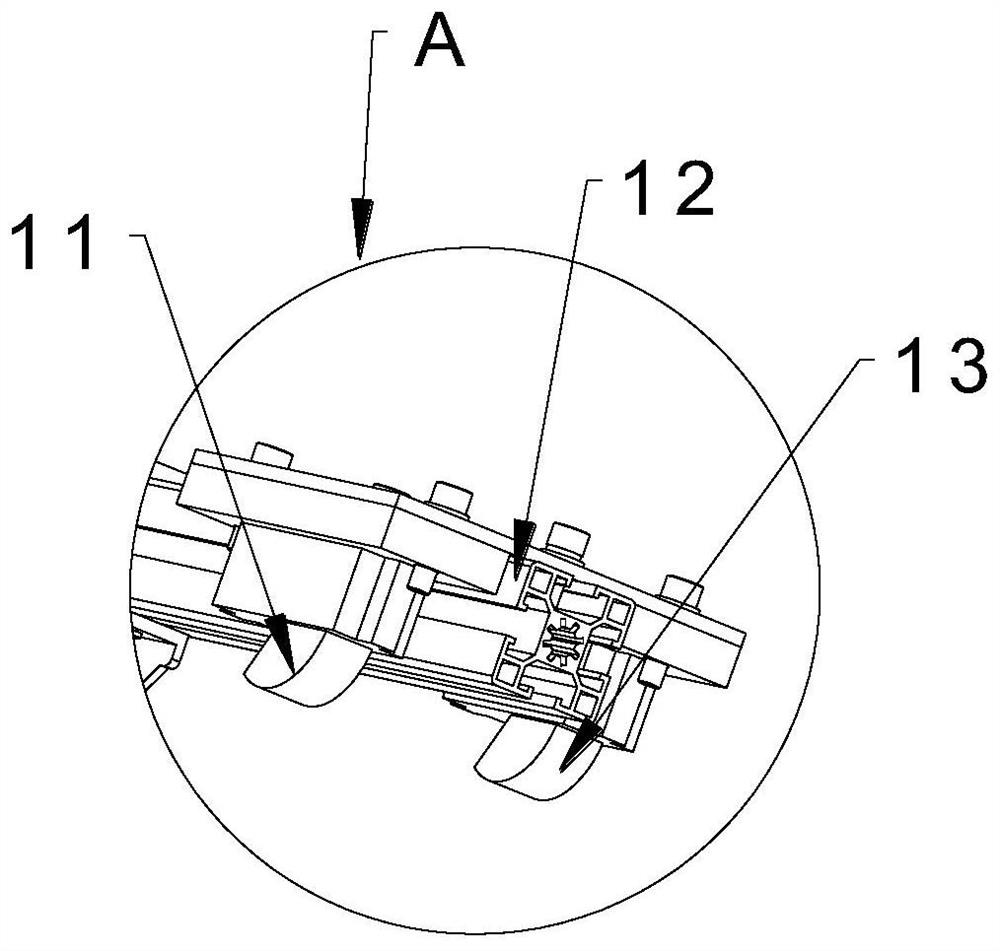

[0050] see Figure 1 to Figure 7 , the present invention is: a photovoltaic module cleaning robot contact type solar storage fast charging system, which includes a photovoltaic module 1, a cleaning trolley 2, a line change trolley 4, a light storage power supply 3, a line change track 5, a track frame 6, and a light storage power supply system, charging system for line-changing trolley and charging system for cleaning trolley;

[0051] Wherein, several track frames 6 are distributed on the sides of each row of photovoltaic modules 1, and line-changing tracks 5 are arranged on them, and the line-changing tracks 5 are parallel to the edges of photovoltaic modules 1; the cleaning working mode of the whole robot system is: The line-changing trolley 4 carries the cleaning trolley 2 and walks on the line-changing track 5, and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com