Threaded cylindrical pin fixed type automatic feeding and polishing device

An automatic feeding and polishing device technology, which is applied in the direction of grinding/polishing equipment, surface polishing machine tools, grinding feed movement, etc., can solve the problems of low work efficiency and inability to automatically load materials, so as to improve efficiency and improve Effect of Polishing Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

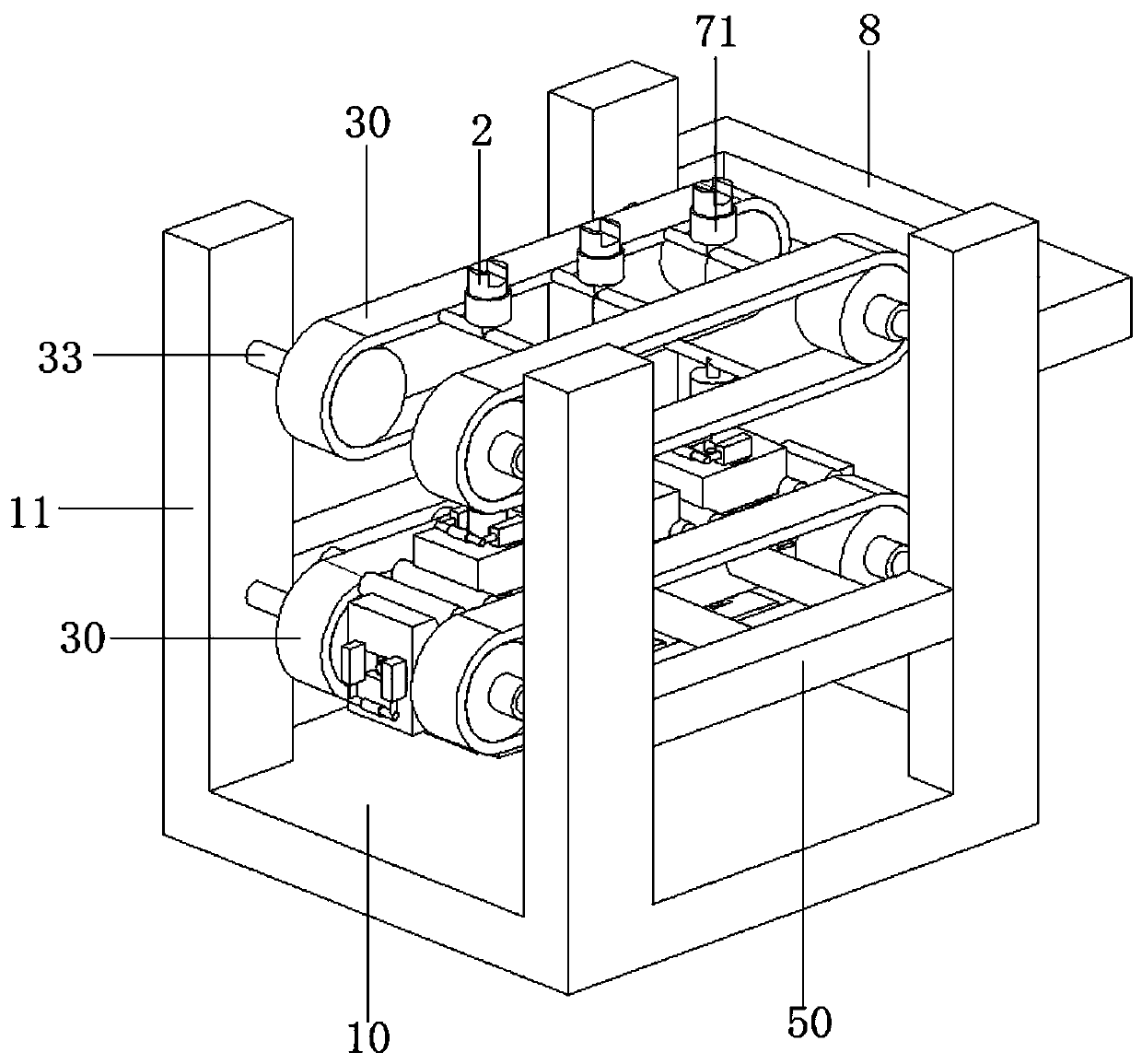

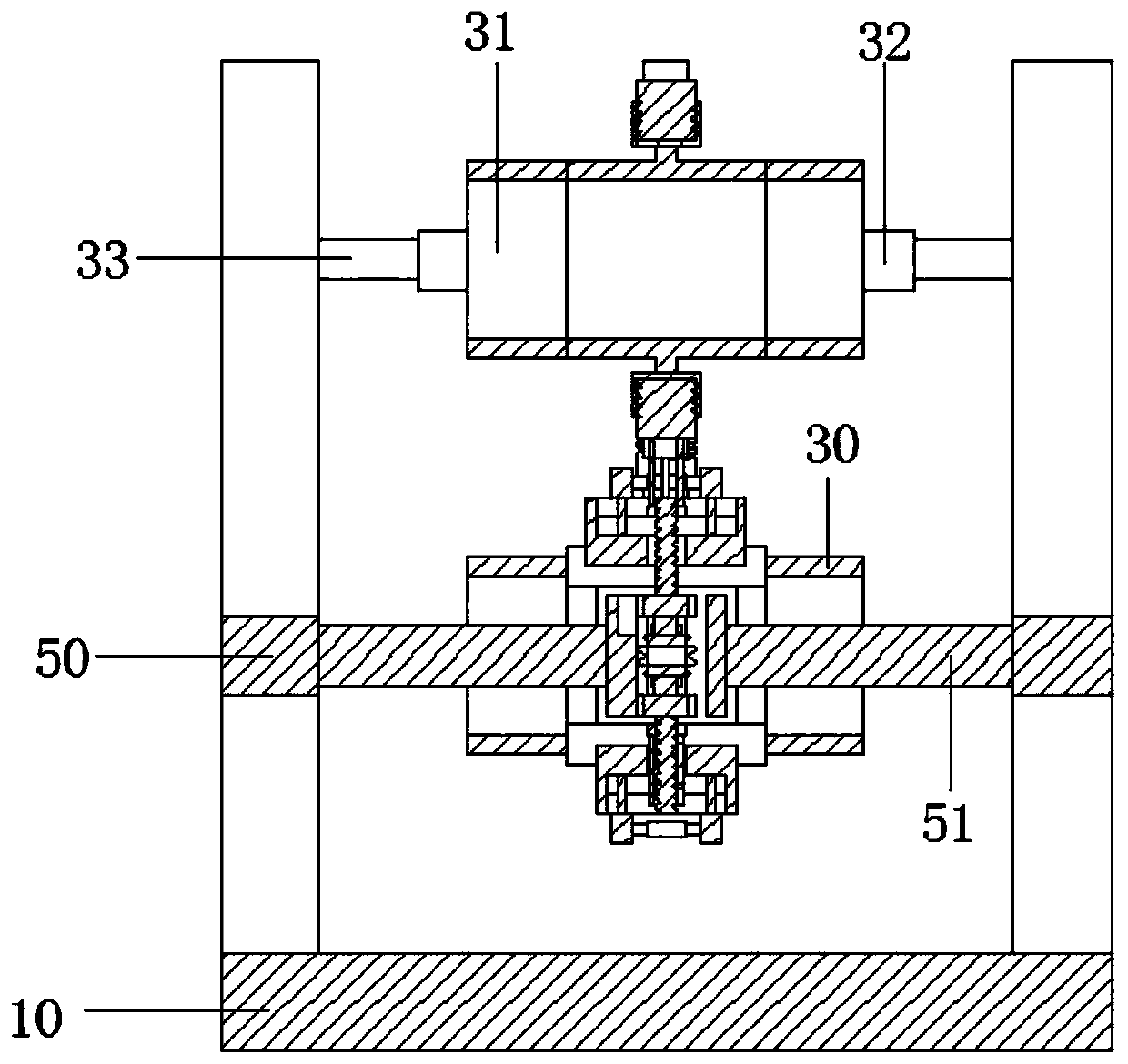

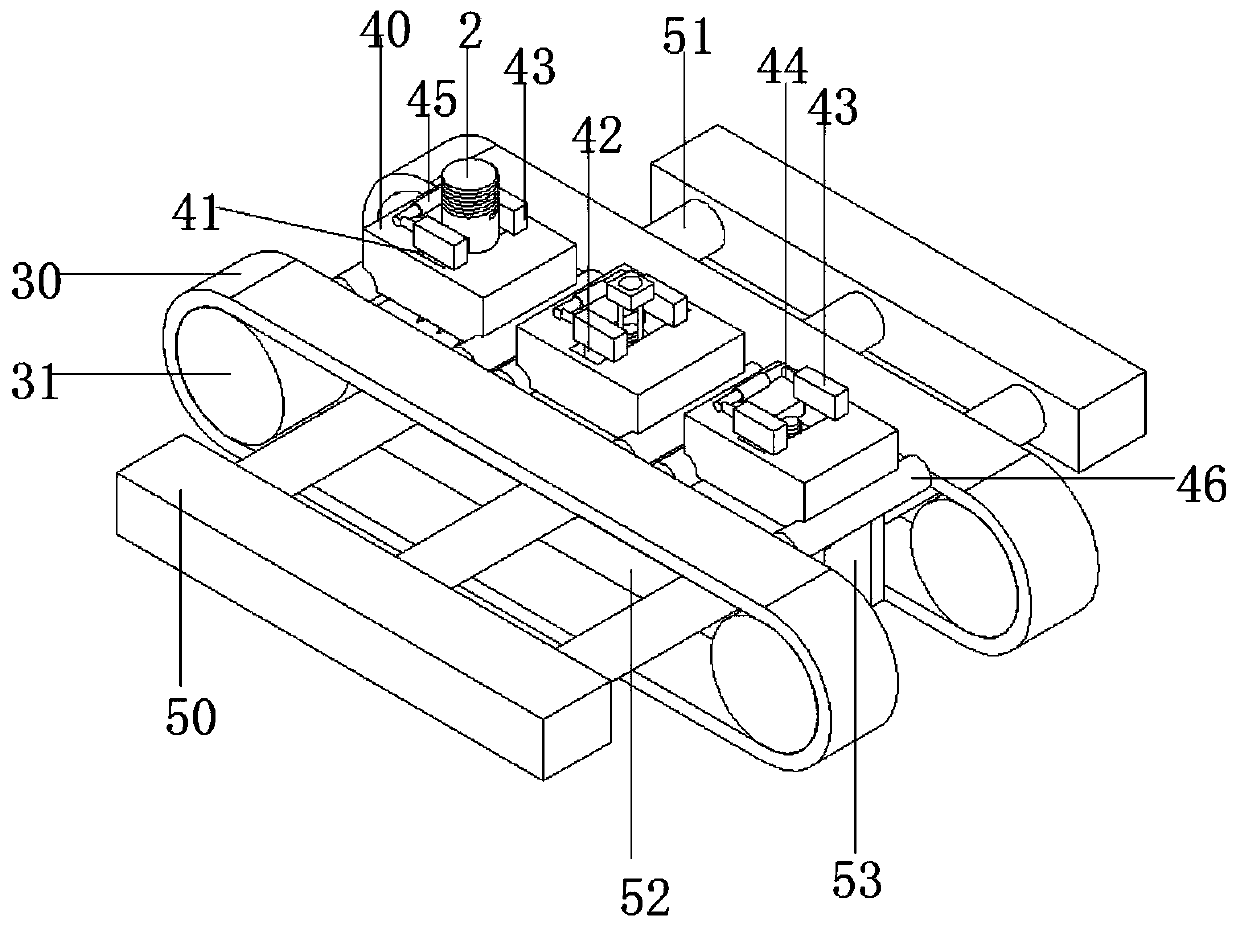

[0037] see Figure 1-11, the present invention provides a technical solution: a threaded cylindrical pin fixed automatic loading and polishing device, including a frame, a threaded cylindrical pin 2, a transmission part, an installation part, a power part, a transmission part, a fixed part and a polishing part 8, the frame It includes a base plate 10 and four sets of vertical plates 11. The vertical plates 11 are equidistant and symmetrically fixed on the four corners of the top of the base plate 10. The threaded cylindrical pin 2 includes a threaded part 20 and a smooth part 21. The center of the bottom end of the smooth part 21 is provided with a pin hole 22. , the transmission part includes two sets of double-cycle chains 30, the installation part includes a mounting plate 40 and two sets of connecting columns 46, the center of the bottom end of the mounting plate 40 is provided with a through groove 47, the horizontal section of the through groove 47 is a square, and the po...

Embodiment 2

[0044] see Figure 1-11 , wherein the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as those in Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between the second embodiment and the first embodiment is that the bottom plate 10 is a counterweight bottom plate and the bottom is a friction surface, there are two sets of support plates 50 and they are symmetrically fixed between the vertical plates 11, and there are three sets of connecting rods 51 and Equidistantly arranged at the center of the side of the support plate 50 .

[0045] The working process of the present invention is: place the threaded cylindrical pin 2 to be polished on the installation part, and use the double-ended threaded telescopic rod 45 and the slider 42 to adjust the gap between the two sets of fixed splints 43 according to the diameter of the threaded cylindrical pin 2 The distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com