Preparation of nickel disselenium-graphene composite material and application for sodium electricity

A composite material, nickel diselenide technology, applied in graphene, selenium/tellurium compounds, nanotechnology for materials and surface science, etc., can solve problems such as poor battery rate performance, active material shedding, poor conductivity, etc. , achieving good cycle stability and rate performance, simple production control, and improved dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of the nickel diselenide-graphene composite material of this embodiment specifically includes the following steps:

[0025] (1): Add graphene oxide to 30mL of deionized water, prepare a graphene oxide solution with a concentration of 10mg / mL, add hydrazine hydrate, stir until the dispersion is uniform, add 2mmol selenium dioxide, 1mmol nickel nitrate and perform ultrasonic dispersion again ;

[0026] (2): Put the mixture obtained in step (1) into a hydrothermal synthesis kettle and keep it at 160°C for 10 hours;

[0027] (3): After the reaction is cooled, the product in the hydrothermal synthesis kettle is separated by suction filtration, washed with deionized water, and freeze-dried to obtain the nickel diselenide supported graphene composite material.

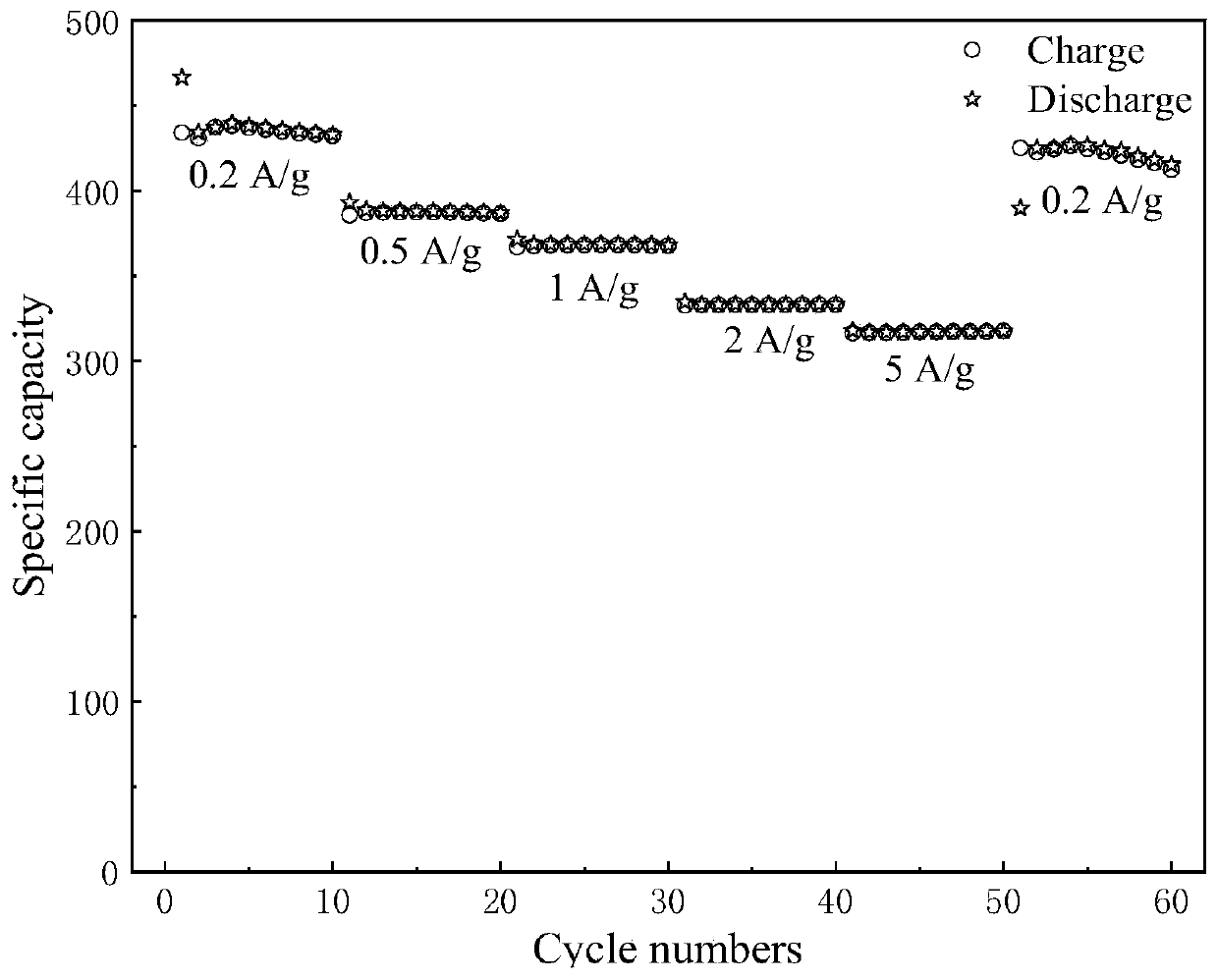

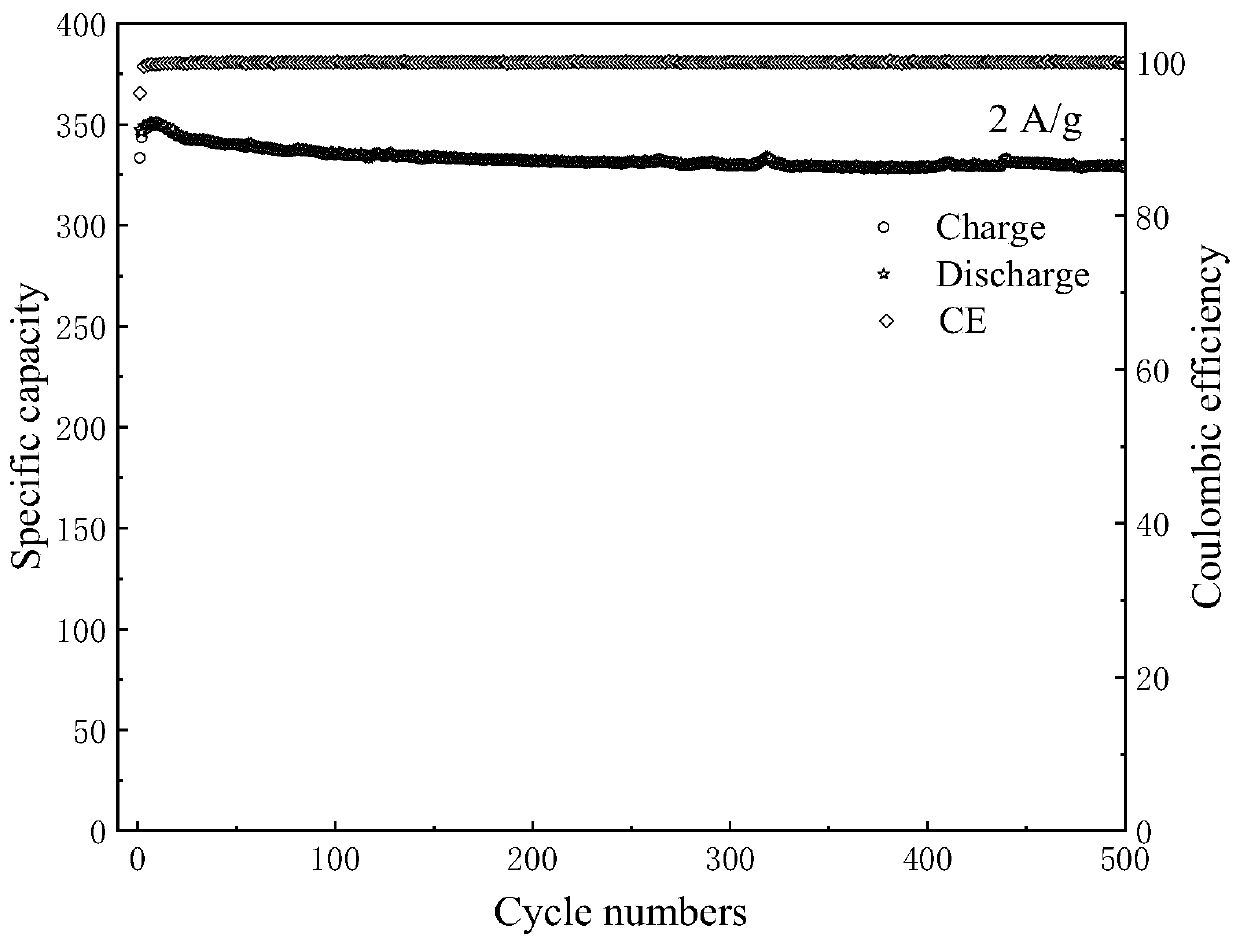

[0028] Using the nickel diselenide-graphene composite material prepared in Example 1 as the negative electrode material of a sodium ion battery: take the nickel diselenide-graphene composite material with a mas...

Embodiment 2

[0032] The preparation of the nickel diselenide-graphene composite material of this embodiment specifically includes the following steps:

[0033] (1): Add graphene oxide to 30mL of deionized water, prepare a graphene oxide solution with a concentration of 5mg / mL, add hydrazine, stir until the dispersion is uniform, add 2mmol selenium dioxide, 1mmol nickel chloride and perform ultrasonic dispersion again ;

[0034] (2): Put the mixture obtained in step (1) into a hydrothermal synthesis kettle and keep it at 140°C for 15 hours;

[0035] (3): After the reaction is cooled, the product in the hydrothermal synthesis kettle is separated by suction filtration, washed with deionized water, and freeze-dried to obtain the nickel selenide-supported graphene composite material.

[0036] The nickel diselenide-graphene composite material prepared in Example 2 was used as the negative electrode material of the sodium ion battery: the nickel diselenide-graphene composite material with a mass ratio of...

Embodiment 3

[0038] The preparation of the nickel diselenide-graphene composite material of this embodiment specifically includes the following steps:

[0039] (1): Add graphene oxide to 30mL of deionized water, prepare a graphene oxide solution with a concentration of 20mg / mL, add dimethylhydrazine, stir until the dispersion is uniform, add 2mmol selenium dioxide, 1mmol nickel sulfate and perform ultrasound again dispersion;

[0040] (2): Put the mixture obtained in step (1) into a hydrothermal synthesis kettle and keep it at 180°C for 5 hours;

[0041] (3): After the reaction is cooled, the product in the hydrothermal synthesis kettle is separated by suction filtration, washed with deionized water, and freeze-dried to obtain the nickel diselenide supported graphene composite material.

[0042] The nickel diselenide-graphene composite material prepared in Example 3 was used as the negative electrode material of the sodium ion battery: the nickel diselenide-graphene composite material with a mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com