Drilling and fracturing integrated machine

An all-in-one machine and splitting rod technology, applied to rotary drilling rigs, drilling equipment and methods, drill pipes, etc., to achieve the effects of improving work efficiency, reducing volume, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

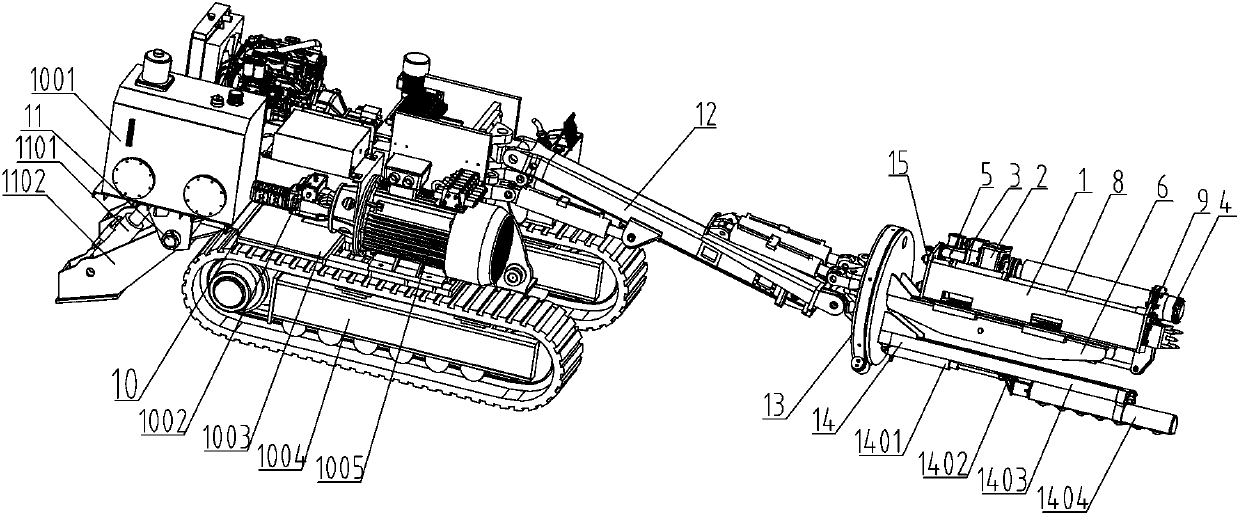

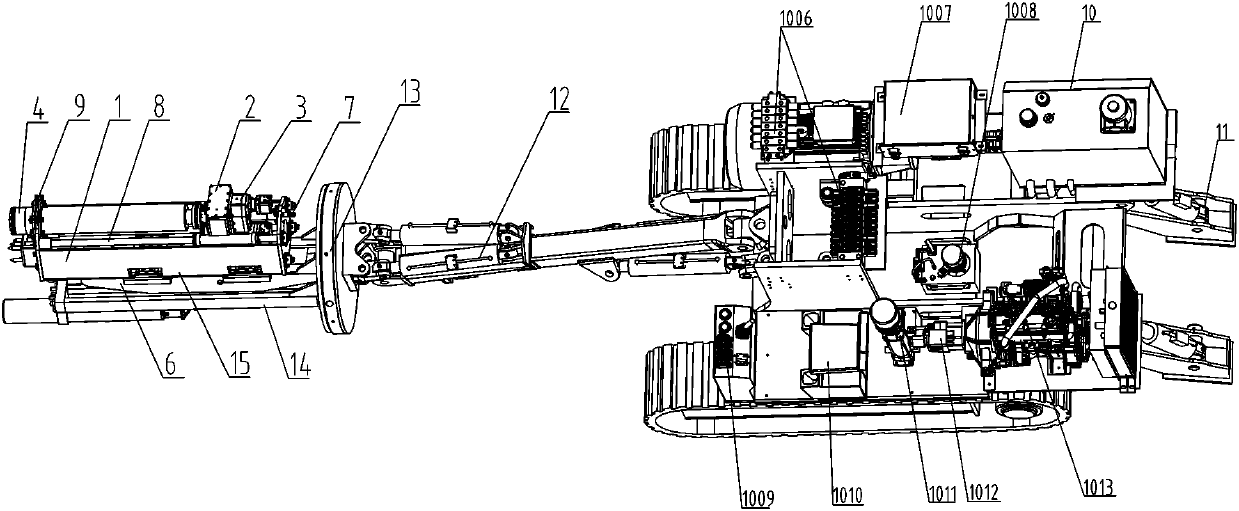

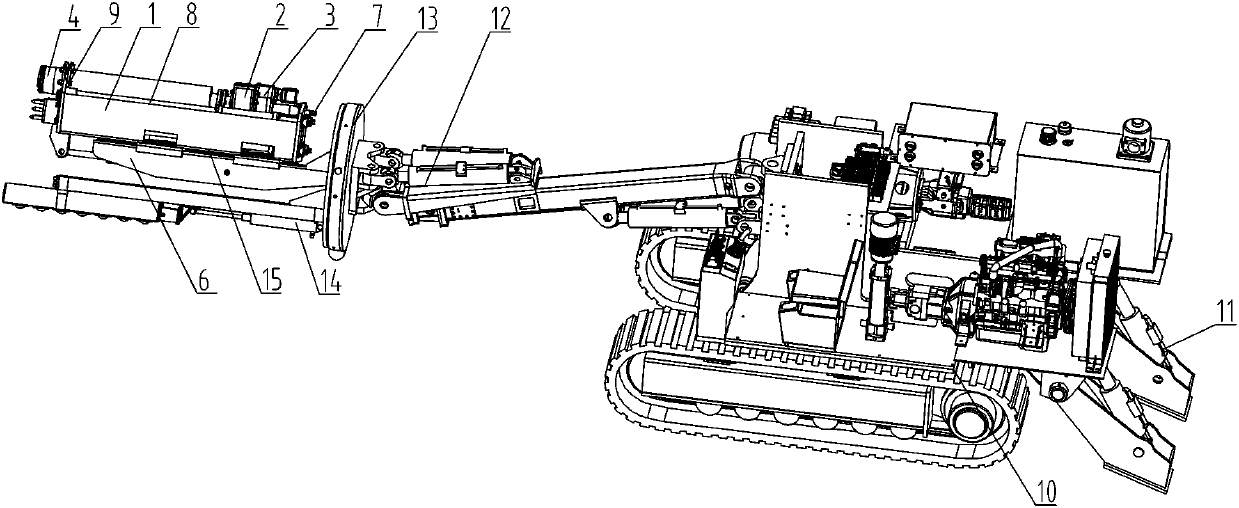

[0058] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0059] see Figure 1-10 , a drilling and splitting integrated machine, which includes a chassis system 10 for carrying the entire device, and a rear support device 11 for positioning and supporting the entire vehicle body is installed at the rear of the chassis system 10, and is characterized in that: the chassis system The head of 10 is equipped with a working arm 12 through a support frame, and the end of the working arm 12 is equipped with a rotary deceleration device 13, and a drilling device 15 for drilling is fixedly installed on the side wall of the rotating disk of the rotary deceleration device 13. And the splitting device 14 that is used to split the rock mass. The all-in-one machine of the above-mentioned device realizes its steering transposition through the rotary deceleration device without moving the body after drilling, and then automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com