Panel gas treatment method based on treelike oriented long drilled holes gradually increased step by step in zones

A step-by-step, long-drilling technology, applied in gas discharge, earthwork drilling, safety devices, etc., can solve the problems of plane and profile drainage blind areas, low drilling utilization rate, unbalanced drainage, etc., to improve Governance efficiency, the effect of non-blind area extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

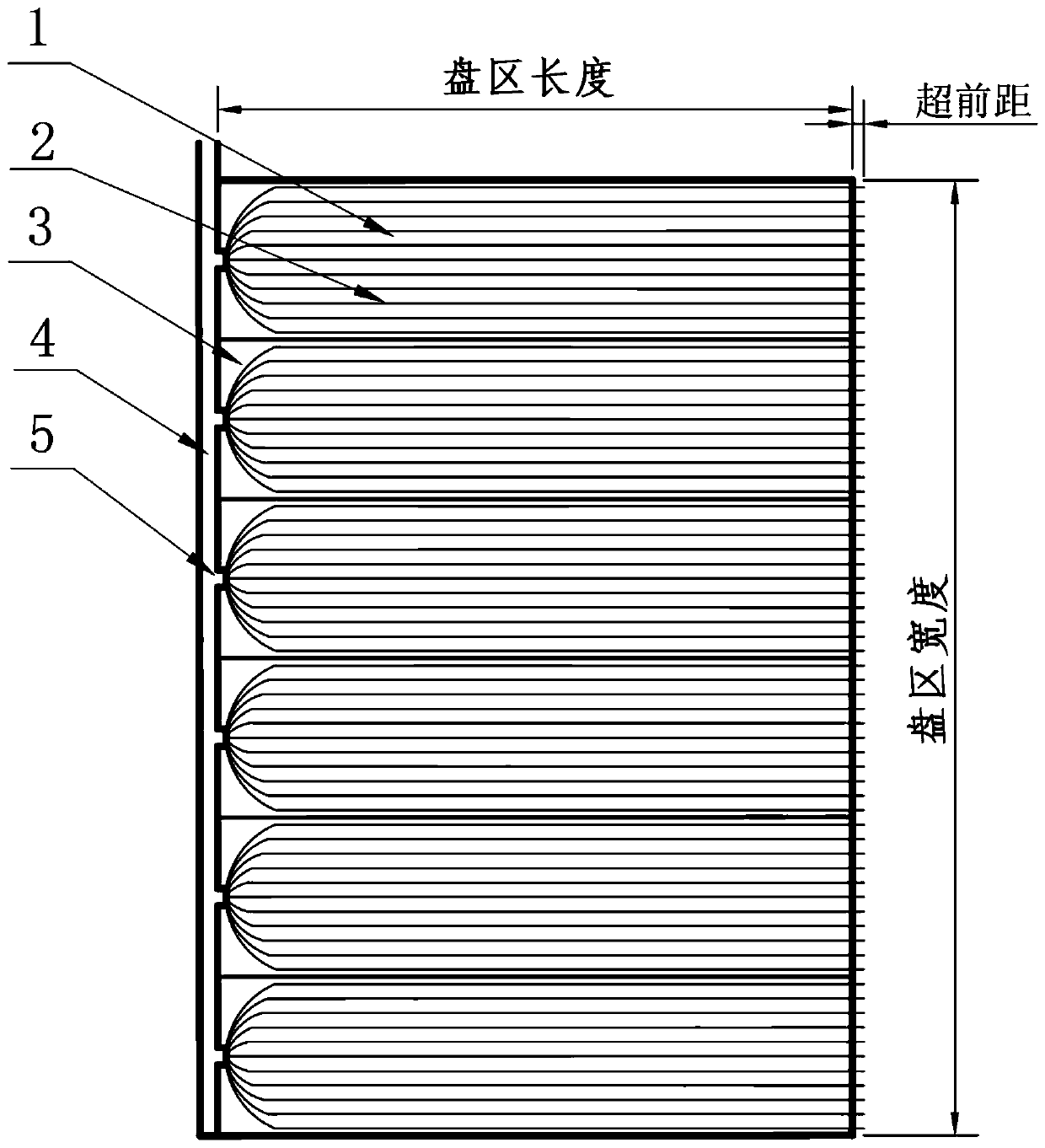

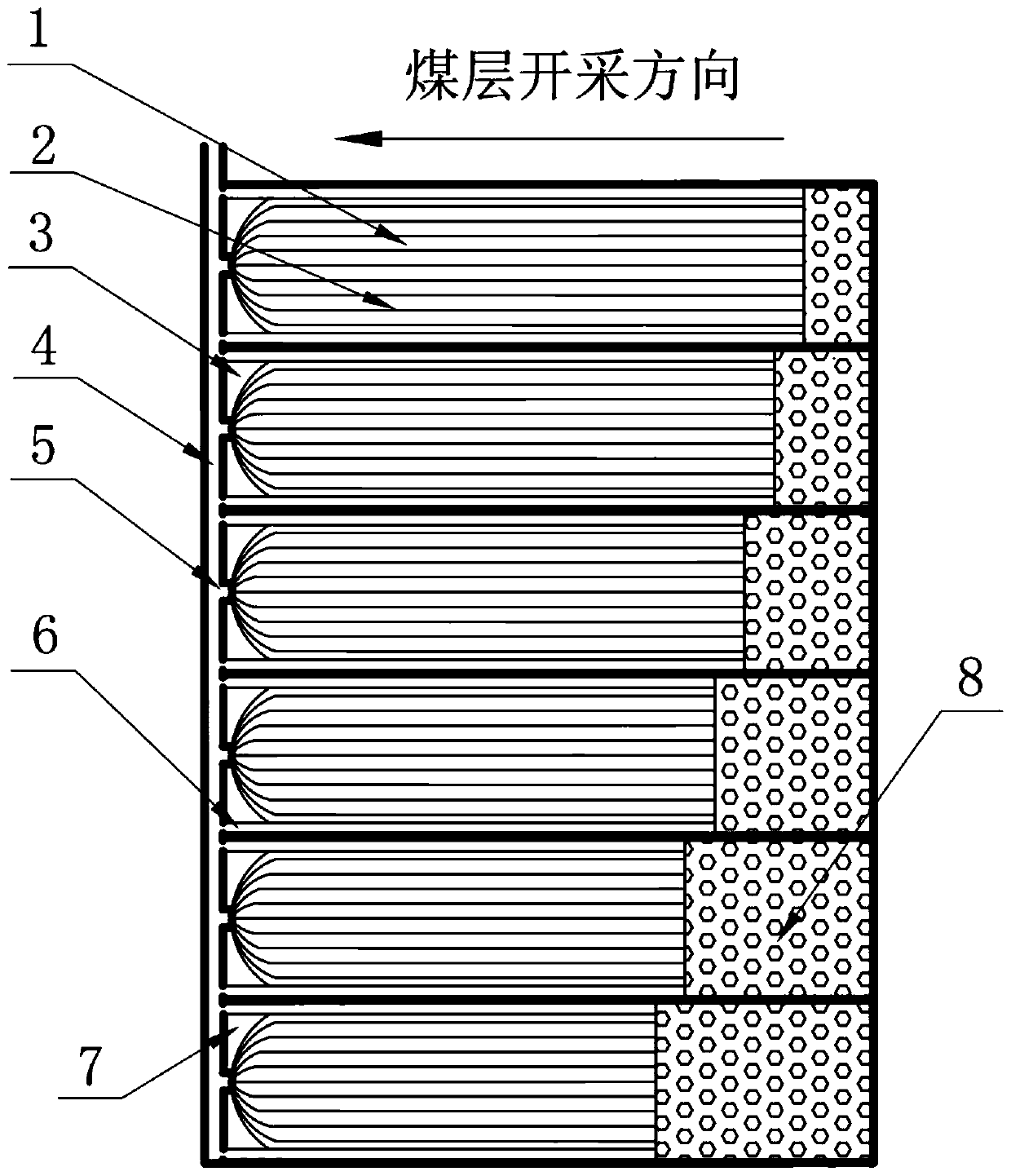

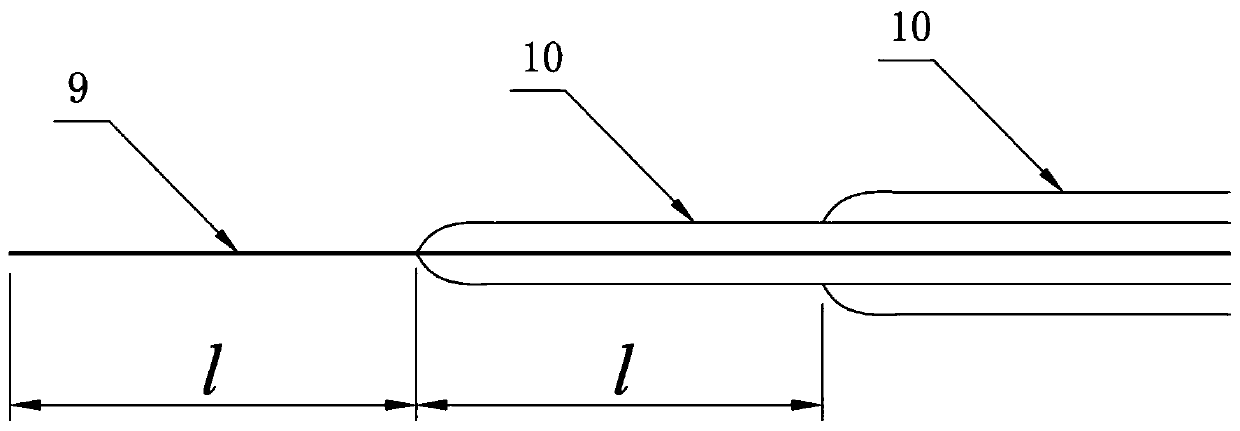

[0043] see figure 1 and 2 , shows the panel gas control method based on the partition step by step tree-like directional long drilling of the present invention.

[0044] The panel gas control method based on step-by-step incremental tree-like directional long drilling includes the following working steps:

[0045] Step 1: Set up the panel area and the mining face. Specifically, the width of the panel area 1 can be determined in the direction perpendicular to the direction of the coal seam according to the mine boundary; The strike direction determines the length of the panel 1; a plurality of mining working faces 3 are arranged in the panel 1 parallel to the strike direction of the coal seam.

[0046] Step 2: Carry out the excavation of the main roadway of the panel and the layout of the drilling site. The main tunnel 4 of the panel 1 is excavated at the edge of the panel 1 along the width direction of the panel 1 , and a plurality of drilling sites 5 are arranged at interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com