Temperature regulation pre-treatment working system

A pretreatment and work-making technology, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., to achieve the effect of creating economic benefits, energy saving and emission reduction economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

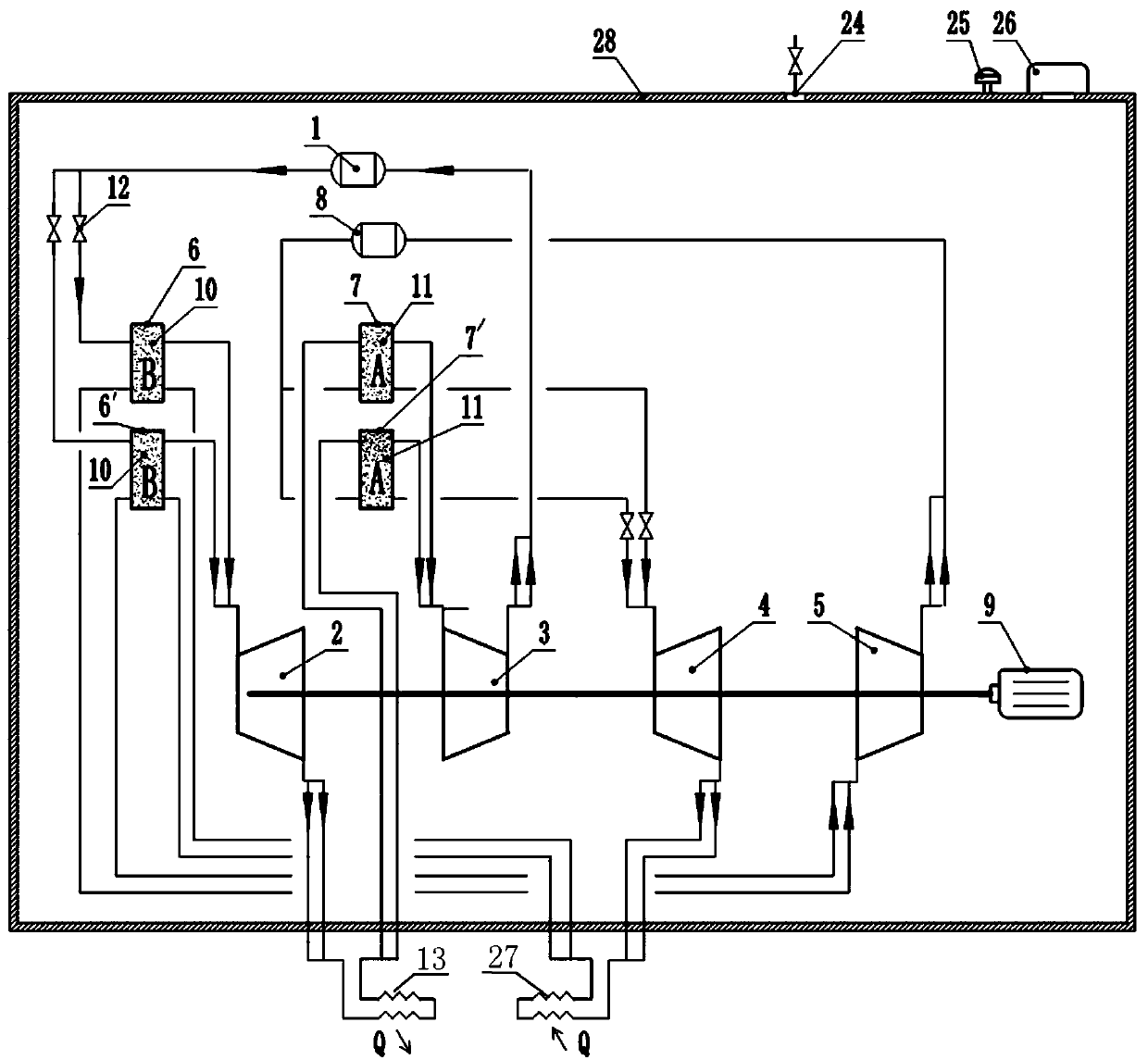

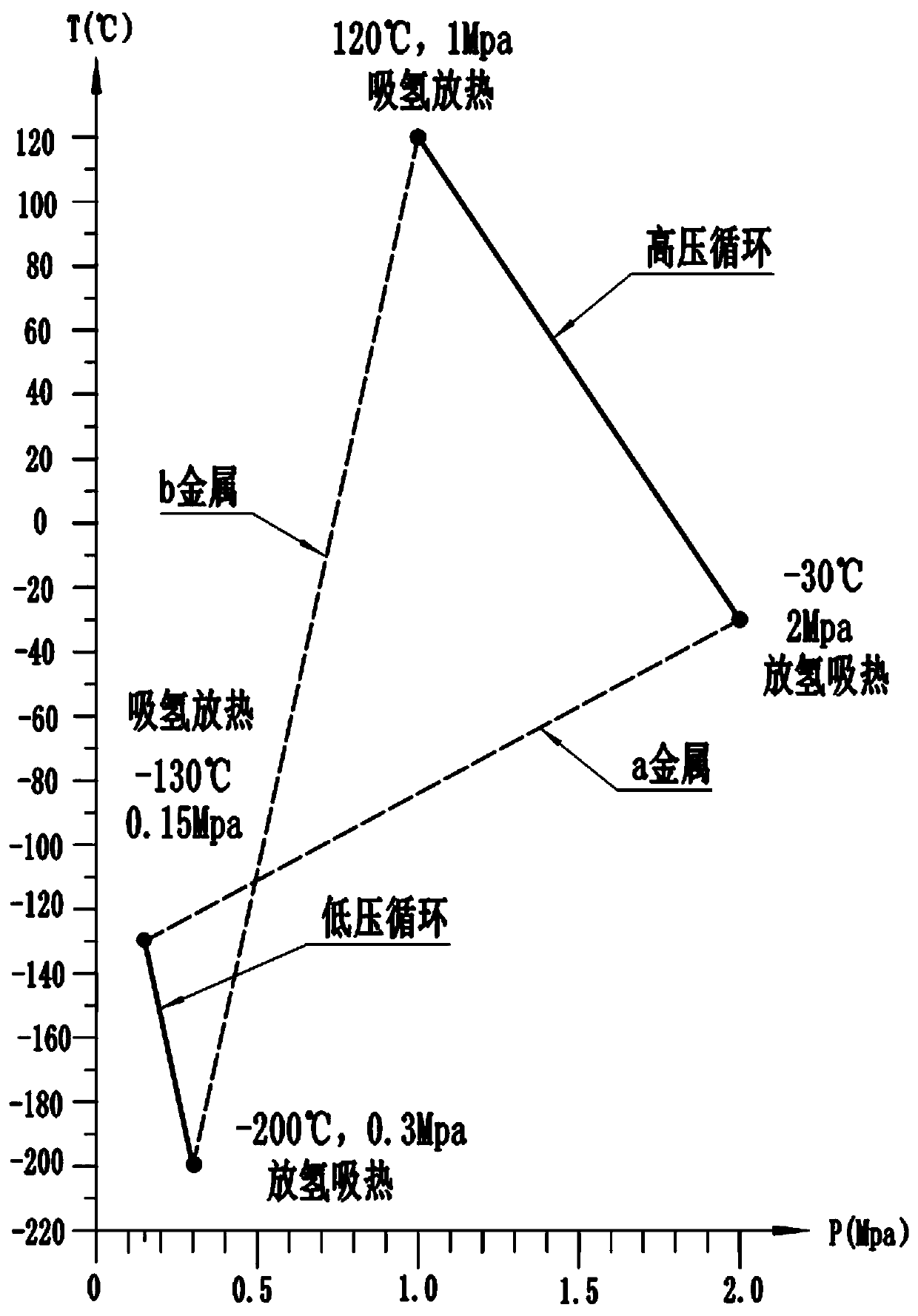

[0029] The invention provides a work system using a hydrogen reaction bed for temperature adjustment pretreatment, such as figure 1 As shown, the working system includes a high-pressure tank 1, a high-pressure expander 2, a high-pressure compressor 3, a low-pressure expander 4, a low-pressure compressor 5, No. 1 temperature changer 6, No. 2 temperature changer 7, and No. 3 temperature changer 6', No. 4 temperature changer 7', low pressure tank 8 and generator 9.

[0030] Specifically, No. 1 temperature changer 6, No. 2 temperature changer 7, No. 3 temperature changer 6' and No. 4 temperature changer 7' are respectively provided with a hydrogen absorption inlet, a hydrogen absorption outlet, a hydrogen discharge inlet and a hydrogen discharge outlet.

[0031] The outlet of high-pressure tank 1 is connected to the hydrogen suction inlet of No. 1 temperature changer 6 and No. 3 temperature changer 6' through valve 12, and the hydrogen suction outlet of No. 1 temperature changer 6...

Embodiment 2

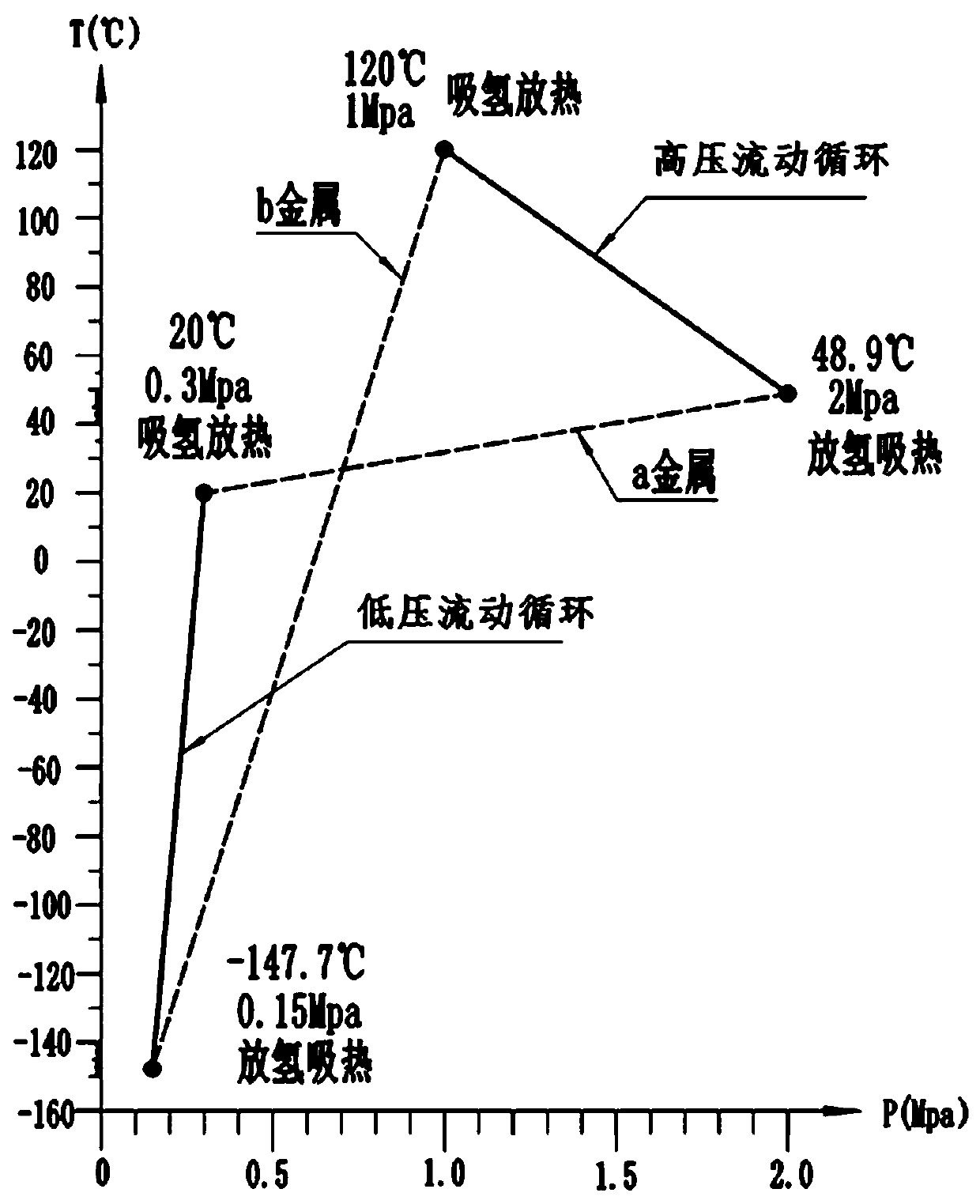

[0055] The working process of this embodiment is completely the same as that of Embodiment 1, the difference is that the working parameters of the system are adjusted. Among them, the B metal hydrogen storage material absorbs hydrogen and releases heat at temperatures below 120°C and above 1 MPa, and releases and absorbs heat at temperatures above -147.7°C and below 0.15 MPa. A metal hydrogen storage material releases hydrogen and absorbs heat above 48.9°C and below 2MPa, and absorbs hydrogen and releases heat below 20°C and above 0.3MPa. The four state points are as follows: image 3 shown.

[0056] In this embodiment, the specific process of a time sequence when the power system is working is: 2MPa at the outlet of the high-pressure tank 1, the high-pressure hydrogen at 34°C first enters the No. 1 temperature converter 6, and the B metal hydrogen storage material absorption part in the No. 1 temperature converter 6 Hydrogen releases a large amount of heat to raise the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com